Researchers in Switzerland have devised an ultrafast biomass splitting process using flash light irradiation to convert dried biomass powders such as banana peel into valuable gases and solids, including hydrogen and biochar.

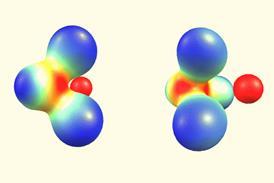

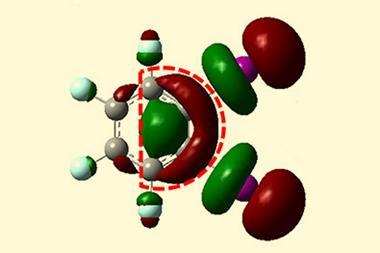

‘The process works through heating molecules under flashes of intense white light to split molecules into smaller gaseous ones and solids,’ explains Hubert Girault at the Swiss Federal Institute of Technology Lausanne. Xenon lamps produce bright white light that closely mimics natural sunlight and enables the temperature to reach over 1000°C for a few milliseconds.

Banana peel contains plenty of carbon, hydrogen and oxygen in the form of carbohydrates, water and proteins. The banana peel is initially dried at 105°C for 24 hours to remove moisture before being ground and sieved to create a thin powder. Then, in just 14.5 milliseconds, exposure to a flash of a xenon lamp generates 100 litres of hydrogen (along with carbon monoxide, some light hydrocarbons and 330g of solid biochar) per kilogram of banana peel powder. Girault says that ‘if all the banana peels of the world were used to produce hydrogen through photo-pyrolysis, the annual production would be 40 kilotonnes, ie the theoretical annual production of a 300 megawatt electrolyser,’ – such high-power commercial electrolysers don’t exist at present.

It’s not only bananas that are ripe for conversion; the process also works with corncob, orange peel, coffee beans and coconut shell, with the potential for a range of other materials that include industrial wastes. Girault’s team is already seeing positive results from experiments splitting rubbers and cooking oils.

‘This is a novel thermochemical route for producing hydrogen from biomass waste without the need to provide additional heat to the reactor, like in conventional pyrolysis, which can increase costs and greenhouse gases,’ comments Ioanna Dimitriou, an expert in the thermochemical conversion of biomass and waste at the University of Nottingham, UK. ‘It also produces high yields of biochar – currently, a promising soil sequestration solution that can achieve significant climate benefits.’

The main problem with the process is the low efficiency of xenon lamps. ‘We’re not going to do an industrial scale-up using xenon lamps, but this academic study illustrates that it is interesting to combine photochemistry with high temperature chemistry, and I believe the future is in solar photo-pyrolysis,’ says Girault. Dimitriou adds that as the processes develop, comprehensive life-cycle analyses and economic assessments will fully assess the environmental and economic benefits of the technology.

‘If you have a flash lamp on your bench, you can do high temperature chemistry without requiring expensive high temperature reactors,’ concludes Girault. ‘There is a whole world of chemistry to be explored here.’

No comments yet