Another step closer to dial-a-molecule reactors

Flow reactors are edging towards self-regulation, thanks to researchers in the UK.

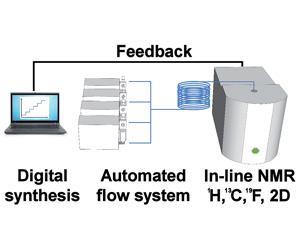

Inspired by previous self-optimised flow systems with in-line analytical monitoring, Lee Cronin’s group at the University of Glasgow has extended this concept so that multinuclear and 2D NMR can be performed in the fume hood.

In addition to performing in-line 1H, 13C, 19F and 2D NMR analysis, the team has combined in-line 1H NMR with computational techniques to make a self-optimising reactor. Their benchtop technology integrates NMR monitoring into a flow system using simple plastic tubing and non-deuterated solvents.

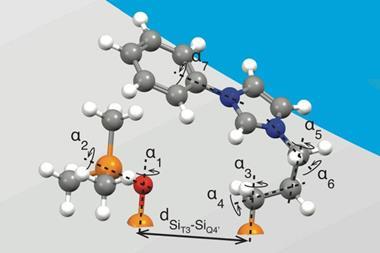

In tests, the reactor followed an acid-catalysed reaction between a benzaldehyde and aniline by integrating specific peaks in the NMR spectra to assess the reaction yield. This data was fed back to automatically adjust the reaction parameters and maximise the yield in real time. This is a key requirement in the concept of ‘dial-a-molecule’ synthesis: the ability to automate optimisation of a reaction through feedback control.

‘Benchtop NMR provides a crucial benefit over previous self-optimising systems using ATR-IR, GC and HPLC as the signals are directly proportional to analyte concentration,’ comments Richard Bourne, a researcher at the University of Leeds working at the interface between chemistry and chemical engineering. He adds that this simpler calibration ‘could lead to an unprecedented increase in the speed at which chemical and process understanding is generated.’

Previous systems integrating in-line NMR spectroscopy had been limited to bypass configurations, flow cells in high-field magnets or microfluidics. Cronin’s approach, however, takes advantage of a compact permanent low-field magnet that can be used even around other magnetic equipment or materials.

Flow chemistry expert Peter Seeberger, from the Max Planck Institute of Colloids and Interfaces in Germany, is impressed by the technology: ‘Incorporating in-line NMR analytics into an organic chemist’s toolbox is going to have a big impact on how quickly and easily complex reactions can be optimised. These initial studies show great potential for this technology and I’m excited to see what comes out of this work.’

‘We hope that people will be inspired to use spectroscopy to monitor reactions in-flow and use it to dynamically control the reaction process parameters,’ explains Cronin. His team plans to advance the technology by combining multiple spectroscopies with more advanced algorithms.

References

This article is open access. Download it here:

No comments yet