Improved sterling recovery cuts environmental impact of solar cell recycling

Burning is better than shredding when it comes to recycling the silver from printed polymer solar cells, new research suggests.

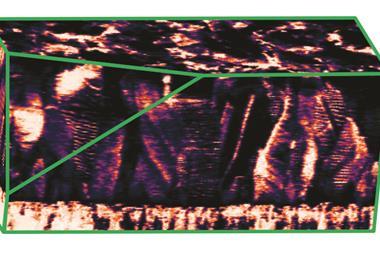

Printed organic photovoltaic cells require the precious metal silver for electrodes, and demand for solar power, and therefore silver, is increasing. Scientists from the Technical University of Denmark (DTU) had previously discovered that by shredding solar cells and soaking them in nitric acid they could recycle up to 95% of the silver that they used when producing the cells. Now, they’ve improved this method – by incinerating the cells first.

In solar cells, plastic foil protects silver from the environment. Incinerating the cell allows easier access to the silver, so the extraction takes less time and uses a weaker solution and smaller volume of nitric acid. ‘We get the same amount of silver, with much less acid, and we reduce 24 hours to 2 hours. That’s what’s causing the footprint to be that much smaller,’ explains Roar Søndergaard, part of the DTU team. They estimate the environmental impact of the silver recycling process to be 20% lower than the previous method.

There’s a further potential benefit to incinerating the solar cells; the plastic burns well and gives out plenty of heat. ‘So we thought if we can burn it and have the organic material contributing to electricity, then you could burn the solar cell to facilitate access to the silver,’ says Søndergaard.

The next step is testing this out at a larger scale in an incineration plant. ‘A modern incineration plant should be able to accommodate this kind of burning. We don’t see any hindrances with this,’ says Søndergaard. A further challenge is to centralise the solar cell incineration to collect the ashes and extract the silver. ‘You need to build a logistics chain to bring the solar modules back to the incineration plants, but it’s a good step in the right direction,’ says Giovanni Nisato, a business and technology development manager from the Swiss Center for Electronics and Microtechnology. Fengqi You, a process systems engineer from Northwestern University, US, adds, ‘Future work on a rigorous life cycle assessment with a more complete life cycle would confirm the superb environmental performance of this process.’

References

This article is free to access until 30 March 2016

R R Søndergaard et al, Energy Environ Sci., 2016, DOI: 10.1039/c6ee00021e

No comments yet