A less labour-intensive bench-top flow method of carrying out organic reactions has been investigated by scientists in the UK.

A less labour-intensive bench-top flow method of carrying out organic reactions has been investigated by scientists in the UK.

Philip Hodge and co-workers at the University of Manchester have used a bench-top flow system to carry out asymmetric Michael reactions. The advantage of this system is that it allows the products of the reaction to be isolated more quickly and easily than traditional methods.

In recent years, one of the most common methods of simplifying isolation has been to attach one of the reactants to an insoluble polymer bead. Once the reaction is complete the species supported on the polymer is easily separated from the others by simple filtration.

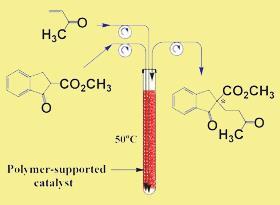

The stirring or agitation involved during reactions can damage the polymer beads. However, by using a flow system (where reactants are allowed to ’flow’ through a column of polymer beads - see figure), the need to stir the reaction is eliminated and the intact polymer beads can be recycled and used again. Flow systems also have the advantage of being able to allow automation of processes.

In Hodge’s system cinchona alkaloid catalysts are supported on gel-type polymer beads and the reactants are passed through the flow system. This gives a high yield of product and when using cinchonidine as catalyst the relative amount of each mirror image form (enantiomer) of product is comparable with those obtained from the batch process.

According to the researchers the potential for further development in this area is huge and Hodge is now working towards developing scavengers that can remove unreacted starting material from flow systems.

Richard Kelly

References

F Bonfils, I Cazaux, P Hodge and C Caze, Org. Biomol. Chem., (DOI: 10.1039/<MAN>B515241K</MAN>)

No comments yet