Nanotecture is gearing up to commercialise a new nanoporous material that it believes will find uses in a wide range of electricity storage applications

University of Southampton,UK, spin-out Nanotecture is gearing up to commercialise a new nanoporous material that it believes will find uses in a wide range of electricity storage applications.

The company, formed in 2003, has initially focused its efforts on optimising the material for use in supercapacitors - and so far has managed to develop supercapacitors that can store three times the specific energy of a standard capacitor at a given power and deliver it three times as fast.

The company believes supercapacitors containing the new materials will find use in a number of applications including starting ’big-rig’ trucks, powering flash modules in mobile phones and in collecting the energy generated by regenerative braking systems like the kinetic energy recovery system (KERS) used in many of last year’s Formula 1 cars.

The key to the material’s appeal is its high porosity, which according to chief executive, Bill Campbell, leads to higher energy storage capabilities and increased power density - and the higher the power density, the faster the charging/discharging process. This means that supercapacitors made from such materials will quickly and efficiently accept the charge from a regenerative braking system, while the current generation of batteries would only be able to accept a small portion of that charge and would waste much of the energy as heat.

Breaking the mould

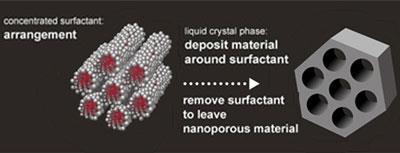

The material is made using a process the company calls liquid crystal templating, in which a surfactant is used to create a template around which the conducting material nickel hydroxide is deposited.

When surfactant molecules are dissolved in water they align themselves so that they minimise the contact between the water and their hydrophobic tails and maximise the contact their hydrophilic polar head groups have with the water. As surfactant concentration and temperature are varied a number of different ordered structures are formed.

According to Kate Amos, Nanotecture’s materials group leader, the liquid crystal hexagonal rods that form at intermediate concentrations are the perfect template around which to deposit materials so that they contain nanopores.

Once the target material is deposited, for instance by the reaction between nickel chloride and sodium hydroxide, the surfactant can be washed away to leave micron sized particles that contain regular pores of around 2nm in diameter - leading to a material with a 100 fold increase in surface area.

Campbell says the firm’s liquid crystal templating approach to material science is ’unique’, and that it has gained interest from a number of different parties. While he is confident of signing up the company’s first client before the end of the year, he warns that it could take 18 to 24 months before any product based on the technology would be commercially available.

But, he says, that is still a relatively short time-scale for such a disruptive technology, which is mainly due to the fact that the materials are easy to handle and do not need any specialist equipment or safety measures to be put in place.

’One of the great things about this approach is because the particles are micron-sized, we neatly side-step the health and safety concerns associated with using nanoparticles,’ says Campbell.

According to a 2009 Frost & Sullivan report entitled World Ultracapacitor Markets, ’with the best of both power and energy density, [Nanotecture’s] type of ultracapacitor promises great strides [forward] for the ultracapacitor market.’

A number of private investors have also been convinced by the technology, with the company having raised $12 million (?8 million) so far. Campbell believes the firm currently has enough money to support its activities and 15 members of staff for the next year - an enviable position for many a start-up considering the recent recession. However, with the company now moving from ’test device development to specific product development’, he did warn that it would be 3 to 4 years before the company was likely to record a profit.

Matt Wilkinson

No comments yet