Modified nanotubes catalyse milder, safer and more selective butadiene synthesis

A catalyst consisting of modified carbon nanotubes makes an important industrial reaction milder, safer and more selective, according to researchers in Germany.

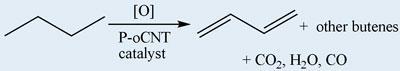

Dangsheng Su and chemists at the Fritz Haber Institute of the Max Planck Society, Berlin, found that by oxidising the surface of carbon nanotubes and adding a dash of phosphorous, they created stable catalysts that could oxidatively strip hydrogen from butane gas more selectively, and under milder reaction conditions, than the complex metals usually employed. The reaction is used to make 4-carbon alkenes including butadiene - a feedstock chemical for several useful polymers such as synthetic rubber and plastic.

Industry currently uses transition metal oxide catalysts (such as vanadium/magnesium oxide complexes) to produce butadiene and other alkenes from butane. To boost activity, these reactions use high temperatures and lots of oxygen, but the conditions can oxidise alkene products, leading to low selectivity for butadiene.

The new process not only runs at lower temperatures (400?C), but requires far less oxygen. The nanotubes compare favourably with the best metal oxide-based catalysts on the market for converting butane into butenes, Su says - and they were nearly twice as selective for butadiene, the most useful component of the mix.

’This marks the first time that n-butane has been activated by a metal-free process,’ Su says, though so far the reaction has only been run at laboratory scale. And he adds that ordinary air could be used in place of pure O2, making the reaction safer. ’Our catalyst has great potential to produce alkenes under very selective, mild and safe conditions.’

’I think this work will have a big impact in the area of alkane activation and catalysis in general,’ says Daniel Resasco, an expert in carbon nanotubes and catalysis at the University of Oklahoma. ’Normally, getting such high selectivity of alkenes in reactions like this is difficult because the alkenes are more reactive than the starting alkane. But it seems that nanotubes are able to do this very effectively.’

Key to the nanotube catalysts’ success, Su’s team found, is that after being refluxed in nitric acid, their surface is covered with ketonic carbonyl groups (C=O), which activate C-H bonds in butane and are recycled during the reaction. Adding small amounts of phosphorous further improves the alkene yield. The team think the phosphorous covers up nanotube defects, preventing them reacting with oxygen and producing electrophilic oxygen species that would destroy the alkene products.

Carbon nanotubes have found roles as catalysts before, such as in converting ethylbenzene into styrene. But butane is less reactive than ethylbenzene, so the researchers were surprised to find that it worked so well.

If carbon nanotubes find success in catalysing an important reaction like this on an industrial scale, Resasco adds, then it may spur research into this area, which will in turn further cut the cost of making nanotubes.

Lewis Brindley

Enjoy this story? Spread the word using the ’tools’ menu on the left.

References

et al, Science, 2008, DOI: 10.1126/science.1161916

No comments yet