Novel hydrogen-bonded coating protects living cells in bioengineering applications

A highly permeable shell made for living cells could substantially extend their lifetime in bioengineering applications, including aiding bone repair, say US scientists.

Vladimir Tsukruk and colleagues at the Georgia Institute of Technology, Atlanta, in collaboration with a team at Wright-Patterson Air Force Base have developed a coating that offers cell survivability of around 80 per cent up to six days. Current coatings allow a lifespan of only a few days and a survivability rate of 20-30 per cent.

Living cells are used in applications such as biosensors and tissue engineering. For example, stem cells can be incorporated into a bone fracture or a wound to encourage tissue regeneration. In such hostile environments, the cells require a protective coating that doesn’t block the diffusion of nutrients that keep the cells alive. Tsukruk says that weak permeable shells are not easy to assemble. ’They become unstable and decay within a few hours,’ he says. Robust shells are made by alternating cationic and anionic polymer layers, but the cations’ positive charge can kill cells.

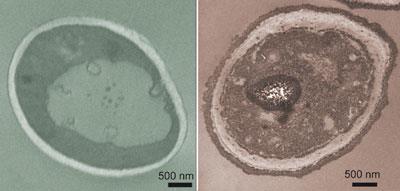

Tsukruk’s team developed their coating using hydrogen bonding rather than ionic forces, which causes less disruption to the cell. The coating combines tannic acid, a naturally occurring weak acid with antioxidant and antibacterial properties, and poly(N-vinylpyrrolidone), a neutral non-toxic polymer. Both components are known to be biocompatible and they form a pH stable shell with a porous surface structure, which is permeable to essential cell nutrients.

’The chemical and practical procedure must be compatible with the cell viability,’ says Francesca Cavalieri of the University of Rome ’Tor Vergata’, Italy, who specialises in designing polymer structures such as microcapsules for drug delivery and tissue engineering. She agrees that Tsukruk’s use of hydrogen bonding is minimally invasive but warns that ’an increase in temperature could break the hydrogen bonding interaction and disassemble the multilayer film’.

Tsukruk’s group hopes to develop their research further to remove all cationic components from the coating to further increase cell viability.

Erica Wise

Link to journal article

Hydrogen-bonded LbL shells for living cell surface engineeringVeronika Kozlovskaya, Svetlana Harbaugh, Irina Drachuk, Olga Shchepelina, Nancy Kelley-Loughnane, Morley Stone and Vladimir V. Tsukruk,?Soft Matter, 2011, 7, 2364DOI:10.1039/c0sm01070g

No comments yet