Carbon nanotube and silicone composite used to make clever actuator

Scientists in China have flexed their muscles with a new steam-driven actuator made from a carbon nanotube and silicone rubber composite. Potential applications of this design include artificial hearts, sensors and soft robots.

Actuators convert energy in various forms directly to mechanical energy, in this case behaving like muscles in response to a stimulus. The biomedical community anticipates using actuators to replace damaged muscles. However, actuators’ complexity and poor durability have hindered their foray into the clinical world.

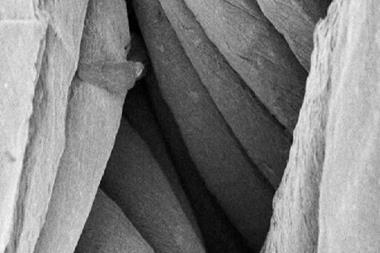

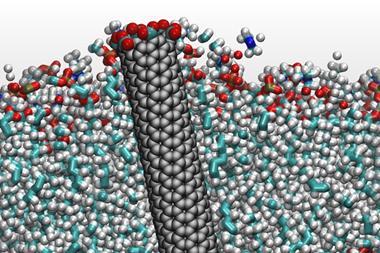

Changhong Liu, Shoushan Fan and colleagues at Tsinghua University introduced an actuator based on phase transitions of water to overcome these limitations. The actuator is made of highly elastic silicone. A carbon nanotube film acts as the electrical heater embedded within the chamber. When a voltage is applied, this interior heater boils water enclosed in the chamber, creating steam. This can inflate the top, thin membrane to six times its original size. Cutting the voltage returns the actuator to its previous state.

There are several advantages of this scheme over both ionic and pneumatic actuators including its easy fabrication, low weight, low driving force, and large volume expansion.

To prove its potential in the biomedical field, the team created an artificial circulation system. Two actuators expanded and contracted to push water through the system with valves in place to ensure water flows in one direction, akin to blood in a heart. While the voltage controls actuation speed and growth, the inherently slow cooling of air causes a significant lag time while the actuator returns to its initial state.

George Spinks, an expert in materials engineering from the University of Wollongong, Australia, warns that ‘a clear limitation of the current system is the very low energy conversion efficiency … which will drain batteries quickly and limit usefulness of these actuators in portable devices.’

Despite the challenges, Changhong remains positive for the future of this simple method. ‘We think mass production of this new type of actuator is feasible as it is easy to fabricate and the raw materials are easy to collect.’ Improvements are already underway and they hope to report these new findings early this year.

References

This article is free to access until 09 March 2016

Z Zhou et al, J Mater. Chem. B., 2016, DOI: 10.1039/c5tb02715b

No comments yet