Kairos Power, a Californian startup, has received approval for the construction in Tennessee of its Hermes demonstration reactor, which uses molten fluoride salt – rather than water – as a coolant. Molten salt-cooled reactors are considered inherently safer, more flexible and more efficient than their water-cooled equivalents as they operate at much lower pressures. The startup has received authorisation from the Nuclear Regulatory Commission (NRC) for the pilot plant, the first time in 50 years that a non-water-cooled reactor has successfully gone through the construction permit application process, which took nearly two years to complete. ‘Kairos Power is thrilled to have achieved this major regulatory milestone as we make final preparations to start construction at the Hermes site next year,’ said Mark Laufer, Kairos Power’s chief executive.

Kairos’s fluoride salt-cooled, high-temperature reactor uses an efficient and flexible steam cycle to convert heat from fission into electricity. The molten salt differs from a water coolant in that it remains liquid at high temperatures (~600°C) at atmospheric pressure. These molten coolants are considered safer than their water counterparts because the salt remains liquid without pressurisation up to nearly 1400°C, compared with water-cooled systems which only operate at about 300°C at 1.5MPa.

A pressurised water reactor circulates water around the reactor core under high pressure to prevent boiling, both cooling the nuclear fuel and acting as a moderator that absorbs neutrons to help regulate the reaction. The water in the core is heated by nuclear fission and then pumped into a heat exchanger where a separate source of water is boiled to produce the steam that powers the turbines that generate electricity.

Molten-salt reactors pump low-pressure liquid salt rather than high-pressure water through the system so they can operate at higher temperatures, increasing efficiency and economy when generating electricity. The concept is not entirely new, however, as a molten-salt reactor was operational in the 1960s but it could not continue due to budget cuts and proliferation concerns. Since then several types of fluoride salts have been studied for molten-salt reactors with nuclear energy back in the limelight as a low-carbon source of power. ‘Molten salt’s got similar liquid properties to water, you can pump it, it’ll flow through pipes, it has really good heat capacity … salt is cheap, it’s very stable, it’s not toxic,’ explains Nicholas Smith, deputy director of the National Reactor Innovation Centre.

Flibe, the name given to a mixture of lithium and beryllium fluorides, has been custom designed for the Hermes reactor by Oak Ridge National Laboratory researchers. ‘Extensive experience and design information exists from the early US reactor development programme that studied and tested liquid-fuelled molten salt reactors,’ writes Kairos, adding that flibe is compatible with high-temperature structural materials. Additionally, Flibe is not broken down by radiation, does not react violently with air or water and can carry more heat than the same volume of water. ‘In Kairos Power’s reactor, there is no need to provide for make-up coolant since the coolant cannot boil away and … [this] allows more cooling capability under accident scenarios compared to water-cooled reactors,’ Kairos explain.

Radioactive pebbles

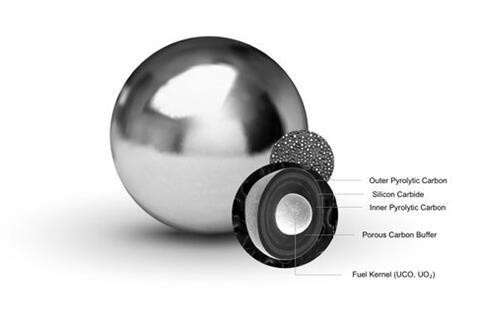

The Hermes reactor will use tri-structural isotropic particle fuel (Triso) pebbles – the most robust nuclear fuel on earth – to heat the flibe coolant. In these pebbles, the uranium fuel is nested inside a graphite-coated silicon carbide structure about the same size as a tennis ball. ‘They’re using a Triso pebble instead of solid fuel rods, which has got safety benefits … the uranium is contained – you’ve got another layer of defence inherently there,’ Smith explains. ‘If one of the pebbles breaks open most of the fission products are soluble in the salt. They don’t just escape the way you know they would in a water system.’

This project is backed by the Department of Energy’s Advanced Reactor Demonstration Program to support industry’s development of advanced nuclear reactors in the US. The $100 million (£79 million) project is expected to be completed by the end of 2026 with the goal of establishing the viability of molten-salt technology. While this pilot plant will not generate electricity, Kairos has ambitions for larger 100MW reactors that will aid decarbonisation. ‘We have made a big step forward on our path to deploying clean, safe, reliable and affordable energy in East Tennessee and beyond,’ Laufer says.

‘I’d love to see the Kairos project successfully come online and start producing power … and have enough success with that first of a kind reactor that another follows,’ says Smith. Molten salt reactors ‘open up a lot of opportunity not just for decarbonisation, but directly using heat from power production’, he adds.

Correction: The permit process in the first paragraph was updated on 7 February 2024

1 Reader's comment