The paper on which this story was based has now been retracted by the authors.

Guided evolution has been used to create enzymes that can functionalise carbon–hydrogen bonds with unprecedented selectivity, so that they are able to precisely amidate their substrates. These new enzymes can be expressed in bacteria and used to make a wide range of lactams – important antimicrobial molecules.

Conventional C–H functionalisation in synthetic chemistry requires reactions that can be tricky to perform and tend to use toxic heavy metal catalysts. The use of enzymes for this kind of reaction offers several advantages as they are easily produced by bacteria and there is often a naturally occurring enzyme that already performs a similar reaction which can be repurposed.

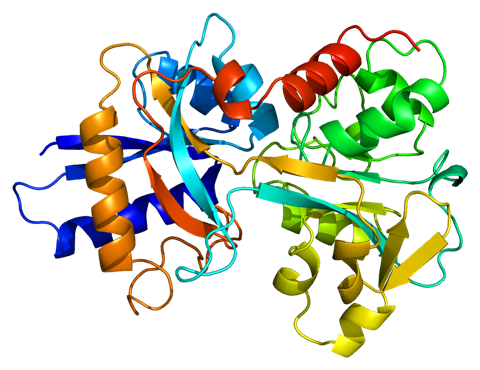

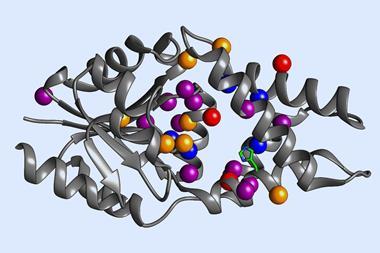

Cytochrome P450 is one such enzyme that naturally replaces the hydrogen in a carbon–hydrogen bond with an oxygen. The team of directed evolution pioneer and chemistry Nobel laureate Frances Arnold tackled the tricky problem of C–H functionalisation by inducing mutations in the genes producing bacterial cytochrome P450 so that they could form a variety of carbon bonds. Successive rounds of mutation, testing and refinement were used to improve the new enzymes.

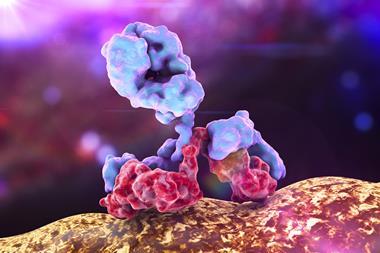

‘We are transforming a carbon–hydrogen bond to a carbon bonded to an amide group,’ explains co-author Inha Cho. The goal of this work was to create lactams and the enzyme can convert a carboxylic acid into a nitrene precursor which can then be cyclised to form a lactam. ‘We are making a variety of lactams, including β-lactams which are important in developing antibiotics because they block receptors in bacterial walls, causing them to disintegrate and die.’

After many rounds of directed evolution Cho and colleagues have produced new cytochrome P450 enzymes that are exceptionally efficient at performing the carbon–hydrogen amidation transformation. By periodically adding the enzyme and substrate over 50 hours they achieved yields of approximately 50% and turnovers of around one million.

Cho says that the method has the potential to produce large libraries of β-lactam containing products with a range of potential antibiotic activities, including some which bacteria are not yet resistant too.

However, while the enzymes are functioning efficiently Cho says there is still room for improvement. ‘The type of lactams we created are still rather simple, and the enzyme does not work well in aerobic conditions.’ To make this method available to all chemistry labs or to scale it up for industry the reaction will need to perform well in air. She also aims to evolve enzymes that target specific C–H bonds within a molecule, so that a single type of substrate can produce different products depending on the enzyme.

References

I Cho, Z-J Jia and F H Arnold, Science, 2019, 364, 575 (DOI: 10.1126/science.aaw9068)

No comments yet