Lithium supplies in Europe and the US will not meet demand for electric vehicle batteries by 2030, despite significant predicted increases in production over this time, new research suggests.

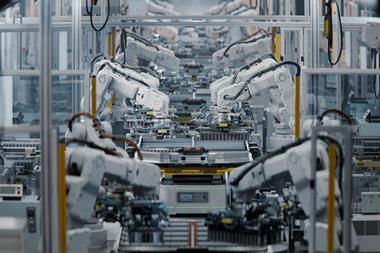

China is predicted to continue its control of the market with greater access to imported lithium and better refining capacity than other regions, as well as a large domestic electric battery industry.

‘China is currently completely dominating,’ explains André Månberger, study co-author and senior lecturer at Lund University in Sweden. Because of this ‘it will become difficult for US and Europe to increase their imports drastically in a short period of time’, he says.

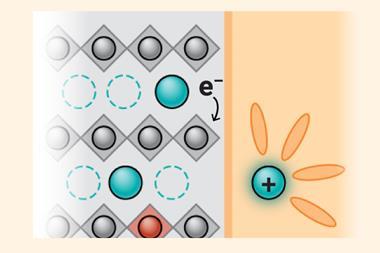

In 2015, the 17 UN Sustainable Development Goals were published. Increasing use of electric vehicles can help achieve seven of these goals. However, lithium is critically important to electric vehicle production so ensuring an adequate supply is essential.

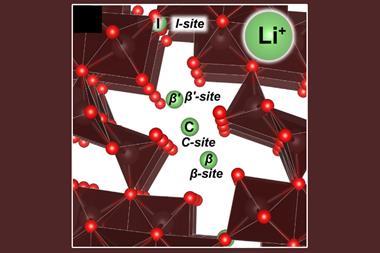

Although global lithium demand is primarily in China, the US and Europe, most natural lithium resources are not in these regions. Australia has the largest known lithium deposits, producing around 50% of the world’s supply. Although China announced it had discovered a large lithium deposit in the Qinghai-Tibet Plateau earlier this year, it still needs to import most of the metal.

Jack Lifton is co-chairman of the Critical Minerals Institute in the US and a leading expert on the economics and markets of critical minerals like lithium. He says China has been more organised about planning its electric vehicle industry than the US or Europe.

‘They went out and bought mines everywhere around the world. For example, they currently co-own the largest hard rock lithium mine in the world in Australia,’ he says. ‘Over the last 20 years, they developed the capability and capacity to transform these mineral resources from the mine to end user components from which they could make batteries and then electric motors.’

Since 2015, when electric vehicle sales accounted for 1% or less of the market in all three regions, production and sales of these vehicles has increased enormously with electric vehicles now accounting for around 50%, 20% and 10% of Chinese, European and US market share, respectively.

The current study predicts that lithium demand will increase in the next five years in all three regions. Production of lithium is also expected to increase from a maximum of 585,000, 12,000 and 34,000 tonnes in China, Europe and the US, respectively, in 2025 to a maximum of 1.2 million, 325,000, and 610,000 tonnes in 2030. In most cases, domestic supply is not predicted to meet demand, with Europe having the biggest potential deficit of around 718,000 tonnes in 2030 in a low supply scenario.

Lifton points out that an important issue with meeting lithium demand by 2030 is that the price of lithium has recently collapsed, leading many mining companies to scale back or close mines. ‘The probability of profitability has to be greater than 50% for them to start something,’ he emphasises. ‘Mining is a hugely expensive undertaking, especially for these less common metals.’

Månberger and colleagues suggest some possible solutions could include promoting research into sodium-based, reduced lithium or smaller batteries, as well as increased recycling of lithium, but acknowledge that the technology for these processes will take time to mature.

Lifton thinks it will be hard to break China’s dominance of the lithium and electric vehicle market any time soon. ‘In five years, the Chinese will be as dominant in battery materials as they are today. Even if everybody started to develop their lithium deposits this minute, in five years, they wouldn’t be in production yet. The Chinese have about a one generation lead on us.’

References

Q Xia et al, Cell Rep. Sustainability, 2025, 2, 100404 (DOI: 10.1016/j.crsus.2025.100404)

No comments yet