Purposeful imperfections programme predictable buckling into soft robotic materials

Researchers in the Netherlands have made headway in creating soft robots that can interact with delicate objects by designing a series of materials that buckle and deform in a predictable manner.

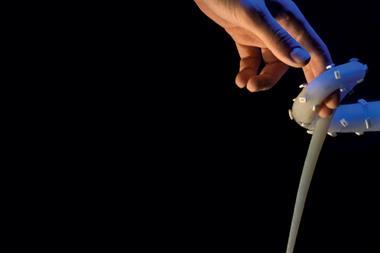

Robotic machinery usually evokes images of large machines carrying heavy loads. Such applications require hard materials that do not bend or break under pressure. Machines for prosthetic devices and robotic surgery, however, require a softer touch.

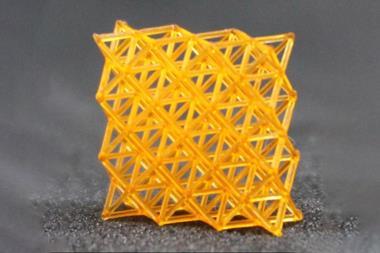

Now, a team led by Amir Zadpoor from Delft University of Technology has devised a system for creating soft robotic materials that builds the macroscopic properties directly into the fabric of the material. Zadpoor says finding materials that have such deformable properties in nature is not possible. ‘No material off the shelf could give you these properties; you really have to design it. With what we are making, there is no distinction between the material and the device.’

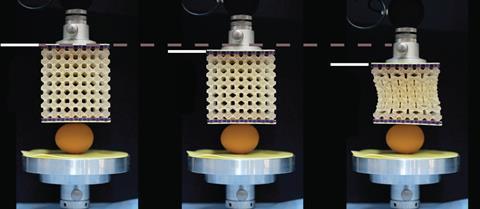

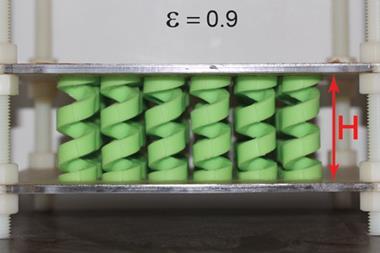

Zadpoor’s team used computational models to design 3D unit cells with different mechanical properties, for example flexible or stiff, that could combine in different ratios to deliver a range of materials with different properties. The designs could then be 3D printed precisely as designed. Through delicate geometrical designs, the group were able to demonstrate an unusual (and perhaps unintuitive) double-sided buckling, where the material bulges outwards in two directions under applied force in one direction.

The medical applications of such soft materials are obvious. However, it’s not just in surgery and prosthetics that these materials could have an impact; the group showed how these materials could act as a force switch, preventing excessive force being applied to an egg once a threshold had been reached, with the material deforming instead of the egg cracking. ‘You could even think about a robot that sorts tomatoes,’ adds Zadpoor.

Julia Greer, a materials expert at California Institute of Technology, US, says that the designs deliver exceptional control. ‘These types of buckling modes open new horizons in using architected materials and this work ties together many of the concepts of folding, origami, symmetry and mechanical properties.’

References

This paper is open access

S Janbaz et al, Mater. Horiz., 2019, 6, 1138 (DOI: 10.1039/c9mh00125e)

No comments yet