Multi-element nanoparticles can now be made with a more diverse array of metals, thanks to a new technique developed by researchers in China. These materials could find use in a wide range of applications due to their interesting and tuneable electronic, chemical and physical properties.

Over the last two decades, there has been growing interest in creating high-entropy alloys – materials made of multiple metallic elements. By mixing elements with different characteristics, researchers hope to discover materials with interesting new properties – for example, they might be better catalysts under environmentally-friendly conditions.

Until now, high-entropy alloy nanoparticles required their components to have compatible properties, such as similar atomic radii or melting points. But now, a team led by researchers at Wuhan University and the Southern University of Shenzhen has found a way to produce nanoparticles that contain elements that were previously difficult to mix together.

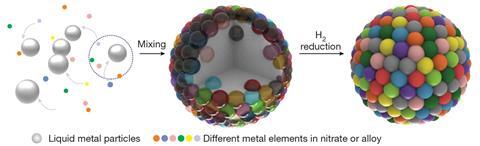

The approach involves using liquid gallium as a matrix to combine many other metals that were otherwise immiscible. In one example, the team produced nanoparticles containing an even distribution of 17 different elements – gallium, iron, nickel, copper, zinc, scandium, vanadium, manganese, magnesium, zirconium, platinum, rhodium, ruthenium, iridium, hafnium, molybdenum and niobium. The elements included in the nanoparticles have melting points ranging from 303–3683K.

References

G Cao et al, Nature, 2023, DOI: 10.1038/s41586-023-06082-9

No comments yet