Materials research borrows technique from drug discovery

Scientists have deployed high throughput techniques traditionally used in drug discovery to double the number of porous liquids that have been characterised.1 Their pool of new porous liquids includes materials with higher gas uptake and use greener solvents than those previously reported.

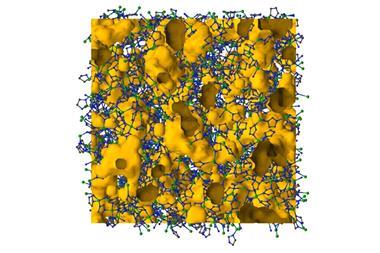

Porous liquids comprise organic cages, which have hollow centres accessible through small windows. Solvents too bulky to fit through those windows dissolve the cages to generate a fluid with pockets of empty space preserved within. The materials can capture greenhouse gasses, remove contaminants from the air, and have the added benefit of flowing through a system for fast separation.

Chemists led by Stuart James, of Queen’s University Belfast, UK, isolated the first permanently porous liquid in 2015.2 Since then, there have only been a few reported examples due to challenges in finding a viable combination of building blocks for their construction.

In a new study, a UK-based team has expanded the number of known porous liquids using a robotic workflow. The group, under the direction of Andrew Cooper and Rebecca Greenaway at the University of Liverpool, discovered 29 new examples.

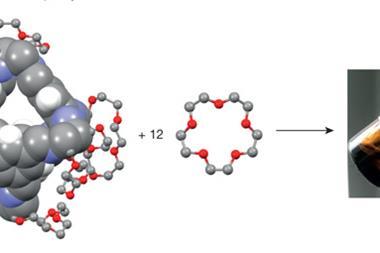

One successful synthesis combined 1,3,5-triformylbenzene with 1,2-diamino-2-methyl-propane and (R,R)-1,2-diaminocyclohexane to create a mixture of organic cages. By varying the identity of the precursor amine and the ratio of the mixture, the group screened 61 cage mixtures and then tested the solubility of successful reaction products in 14 different solvents. With such a large number of variables, Greenaway says that manually synthesising then testing all the possible combinations would likely take half a year in the lab. Instead, the team instructed robots to dispense solutions of each cage precursor into reaction vessels where they heated and agitated the reactions in parallel. For successfully formed cages, a second robot tested their solubility in a variety of bulky solvents. The robot-aided method boosts the efficiency of the discovery process by reducing the time spent on trial and error testing and as a result, the chemists rapidly explored many more combinations than would have otherwise been possible.

‘The science of discovery is about designing the tools and methods to find the unknown,’ comments Jeffrey Moore, a materials scientists at the University of Illinois, US. ‘This work demonstrates an effective strategy to discover the scarcely known property of porous liquids.’

‘This is the first time we have been able to study how changing the components of the liquid affects its overall properties, such as what gasses we can put into the system. Now that we have developed the high throughput methodology, it can be applied to many other porous liquid systems and streamline future discovery,’ comments Greenaway. ‘We have reported more systems in this one study than in the entire literature so far.’

Armed with their new porous liquids and their properties, the group aims to use the information to design function-specific porous liquids.

References

1 R Kearsey et al,Chem. Sci., 2019, DOI: 10.1039/c9sc03316e (This article is open access.)

2 N Giri et al,Nature, 2015, 527, 216 (DOI: 10.1038/nature16072)

No comments yet