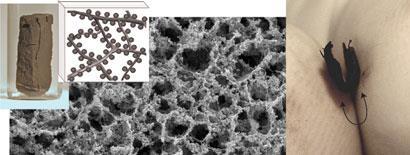

Researchers make magnetic foams and flexible magnetic gel sheets using a cellulose scaffold and magnetic nanoparticles

Flexible lightweight magnetic materials based on cellulose fibres and magnetic nanoparticles have been developed by European scientists. The material can be made into a soft, porous foam or stiffer, paper-like sheets, and could find applications from microwave shielding to fighting banknote fraud.

The international team was led by Lars Berglund at the Royal Institute of Technology (KTH) in Stockholm, Sweden; Olli Ikkala from Helsinki University of Technology in Finland; and Josep Nogu?s from the Catalan Institute of Nanotechnology near Barcelona, Spain. Nogu?s explains that the biggest advantage of the material is that it stays flexible even when it is dried. ’People have made flexible ferrogels - wet polymer gels with magnetic particles inside,’ he says, ’but when you dry them they become very brittle.’

This flexibility comes from the cellulose fibril scaffolding, which is made by bacteria and forms a gel. ’The cellulose fibre gel is freeze dried, then dipped into a solution of iron and cobalt ions,’ says Nogu?s. Warming the whole lot up precipitates the metals which can be converted to magnetic nanoparticles and then freeze dried again. ’Freeze drying means that it doesn’t collapse when you take it out into air,’ adds Nogu?s.

This makes the material extremely lightweight, since up to 98 per cent of its volume is air, but also means that lots of nanoparticles can be included in the structure without aggregating together since they are grown firmly attached to the cellulose structure. This means the magnetisation of the material is quite strong, so it can be moved with relatively weak, household magnets.

Wendelin Stark from the Swiss Federal Institute of Technology (ETH) in Zurich, points out that many magnetically contractible materials often lack the ability to unfold once the magnetic force is removed. ’In this case, the fibrils take up a lot of the strain and then give it back when the force is released,’ he says, ’it’s like incorporating a spring as a material element.’

Because it is so lightweight, Nogu?s thinks that the foam material could perhaps be useful for microwave shielding in mobile phones, cars or aeroplanes, where weight is a significant concern. ’Other shielding materials like metal sheets can be very heavy,’ he says, adding that the flexibility could also make it useful for moving parts like magnetic switches and actuators. By compressing and collapsing the porous structure, the team have also made a form of magnetic paper, which they propose could be incorporated into banknotes to make them harder to counterfeit.

Phillip Broadwith

References

et alNature Nanotechnology, 2010, DOI: 10.1038/nnano.2010.155

No comments yet