Inaugural picture of what happens when materials are bashed together reveals unexpected level of molecular transfer

Computational simulations developed by an international team of scientists have for the first time cast light on molecular-level details about mechanochemical cocrystallisation in a model organic system. Despite the solid crystalline nature of the system, the work revealed significant levels of molecular transfer when cocrystals were pushed together under solvent-free conditions.

Mechanochemistry uses mechanical force – rather than heat, light, electricity or solvents – to initiate a chemical reaction. The field has garnered significant attention as a way of making new materials by simply bashing reagents together in a ball mill. However, a fundamental description of mechanochemical reactions has been hard to come by. Whilst mechanistic models for the fluid state exist, allowing us to image gas-phase and solution-state reactions, little is currently known about solid-state collisions involving crystals.

Team member Michael Ferguson, at the National University of Cuyo in Argentina, says there is a benefit to studying mechanochemical reactions in lieu of traditional solvent-based approaches. ‘The idea behind mechanochemical reactions is that you can do these reactions much faster, so that you can actually screen for cocrystals. With a solvent-based approach, there’s a lot more work-up, a lot more cleaning, whereas with mechanochemistry, you can do the reaction in a fraction of the time,’ he comments.

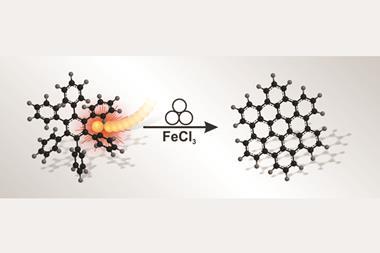

The multidisciplinary project, led by Jorge Kohanoff and Stuart James at Queen’s University, Belfast, UK, and Mario del Pópolo at the National University of Cuyo, combines chemistry, physics and molecular dynamics to seek a better idea of what happens at the molecular level when crystals undergo solvent-free collisions. They applied computational modelling to indentations between crystal particles to mimic the early stages of their interactions.

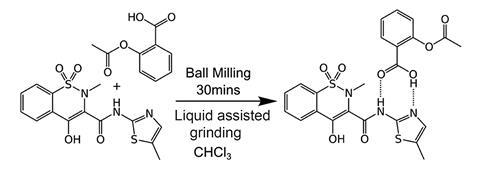

The team ran collision simulations using crystals of aspirin and meloxicam, two common anti-inflammatory drugs, which interact via a hydrogen bond that can be modelled using classical mechanics. ‘We took two blocks of the crystals and cut them into spheres, and we pushed them together so that they would indent upon each other. Then we pulled them back apart to see what the effects of that were,’ explains Ferguson. The team observed solid-state molecular transfer between the crystals, with a surprising number of molecules jumping from one sphere to another just by pushing and pulling.

‘What struck me was that the crystals behave like putty – they almost seem like plasticine and they’re amorphous at these contacts. When you pull them apart there’s a connective neck of molecules in between the two crystals,’ adds James.

Chemical modelling expert Graeme Day, from the University of Southampton, UK, is impressed by the amount of mixing observed between the cocrystals. ‘One indentation of these two particles together and then pulling them apart led to so much of the material getting transferred across. That was one surprising aspect of the study and really stood out,’ he notes. ‘It makes you wonder what happens after these particles react together a few times and you have a build-up of a lot of this mixed amorphous phase. Also, there are lots of other possible cocrystals out there. Would you observe the same amount of mixing or lack of solvent effects if you looked at other cocrystal formers?’

James agrees that studying events on a larger scale is the next step towards being able to model crystalline product phases. ‘I would like to see, over the next few years, this develop to the point where it actually becomes useful in informing us how best to do mechanochemical reactions experimentally,’ he says. ‘I see this as being near the start of a new research area.’

No comments yet