During the Cop28 world climate conference the glitzy yachts moored in Dubai Marina shared their berths with a very different vessel: the world’s first ship that can be powered by ammonia. However, global maritime rules mean that despite the ship being ready to set sail fuelled by ammonia, it’s not currently allowed to.

For an industry that contributes almost 3% of global greenhouse gas emissions and carries 80% of the world’s trade, taking the carbon out of shipping has long been a challenge.

Now Fortescue Future Industries (FFI), the green technology arm of Australian mining company Fortescue, has converted two of the engines on an offshore supply vessel to run on green ammonia. The fuel is produced by combining nitrogen from the air with hydrogen produced through the electrolysis of water. It produces no carbon emissions when burnt. Ammonia is already shipped around the world to produce fertiliser so industry is familiar with handling this hazardous chemical.

Fortescue’s ship the Green Pioneer is designed as a technology demonstrator, to push both regulators and ship engine manufacturers to embrace ammonia. The ship couldn’t use ammonia to fuel its journey to Dubai from its home in Singapore, however, because no regulations permit it. No ports will accept ammonia-powered ships, although the Port of Antwerp–Bruges announced at Cop28 that it will bunker ammonia vessels from 2025. Green shipping corridors will have to be developed so that ports are set up to refuel these vessels at each end of the voyage.

Andrew Hoare, FFI’s head of shipping, told a hydrogen summit at Cop28 that the advance ‘unlocks the regulations, as it hasn’t been done before. We’ve actually helped the regulator the [International Maritime Organisation] … to write the regulations that will ultimately regulate us. If we had done nothing, it would not be possible to move these products in a green fashion for many, many years.’

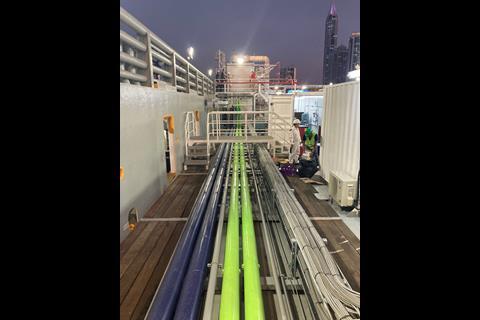

Together with experts from other companies, FFI has spent 18 months developing all the processes and systems required to run the ship, including the gas fuel delivery system. ‘There’s not a single piece of technology on that ship that is completely novel and new. You just use great minds, great brains and bolt it together,’ said Hoare.

The fuel tanks hold about 40m3 of ammonia – enough for a two-week voyage. The ammonia in the tanks is pressurised to 200kPa, but to be fed into the engine the pressure is reduced and the ammonia is warmed using waste heat from the engine.

While there are no CO2 emissions from burning ammonia it does release nitrogen oxides (NOx) that contribute to global warming. Instead of using urea as a NOx scrubber, ammonia is added. The unburnt ammonia mixes with the NOx in the presence of a catalyst to produce nitrogen, oxygen and water vapour. FFI says NOx emissions from its engines are lower than burning diesel, and efforts to reduce them further continue.

Ammonia has a lower energy density than diesel, so engines consume around twice as much by volume. FFI says the higher volume of fuel required is already leading to a new approach to ship design, with a focus on the use of lighter materials.

No comments yet