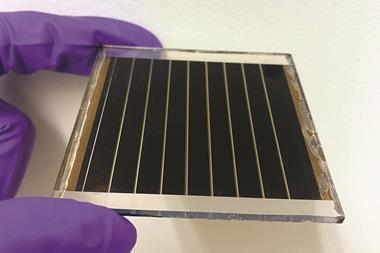

Two groups have independently created perovskite-on-silicon tandem solar cells that surpass 30% efficiency. The two designs use different techniques to minimise losses, but together constitute an important milestone on the road to proving the value of perovskite top layers to silicon solar cells. In the year since the cells were first reported, several other groups have gone on to produce cells of equal or slightly higher efficiency.

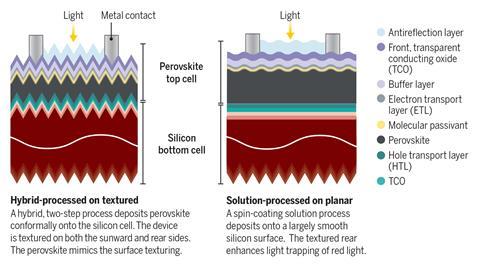

Commercial silicon solar cells generally reach efficiencies of over 24%, and one laboratory device has generated 26.8%. The theoretical maximum for silicon is about 29.5%, so significant further efficiency gains will need to come elsewhere. An obvious target is perovskite-on-silicon tandems: silicon’s bandgap is 1.12eV – the extra energy in higher-frequency photons is wasted as heat. A perovskite top layer with a bandgap around 1.7eV could theoretically increase the efficiency to 45%, but the actual gains have been much less dramatic, with previous record efficiencies all falling short of 30%.

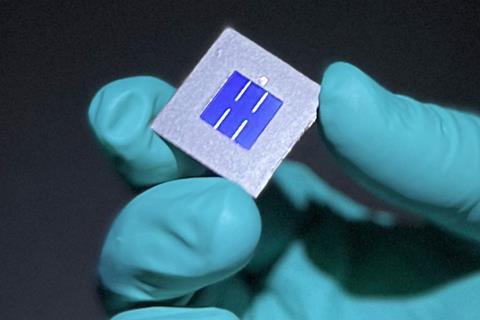

A significant limitation is recombination of electrons and holes at defects in the perovskite and especially around the fullerene normally used to extract electrons from the surface. In one of the new papers, researchers in Germany added piperazinium iodide to their perovskite. This ionic liquid, which contains both electron-donating and electron-accepting functional groups, has previously been shown to reduce recombination at charged defects.1 In the new work researchers led by Steve Albrecht at the Helmholtz Centre for Materials and Energy added the ionic liquid to a different perovskite and, using various spectroscopic techniques, showed that it facilitates swift charge extraction by forming a dipole between the perovskite and the fullerene, thereby suppressing recombination. They used this to produce a solar cell with a certified power conversion efficiency of 32.5%.2

In the other paper, Xin Yu Chin at EPFL and the Swiss Centre for Electronics and Microtechnology, together with colleagues around the world, mitigated not only the problem of defect recombination but also the physical issue that the most efficient silicon solar cells have chemically or physically textured surfaces to minimise their reflectivity. The usual solution deposition production process flattens this.

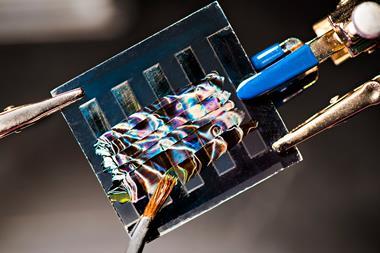

Chin and colleagues began by self-assembling a layer of [4-(3,6-dimethyl-9H-carbazol-9-yl)butyl] phosphonic acid into a coating on indium tin oxide-covered textured silicon. This formed the hole-transport layer. They then thermally evaporated caesium bromide and lead iodide onto the surface. Finally, they deposited formamidinium bromide and formamidinium iodide, sometimes mixed with 2,3,4,5,6-pentafluorobenzylphosphonic acid from solution, and thermally annealed the resulting mixture to form an organic–inorganic perovskite on the textured surface.3

When the researchers analysed the crystal structure of the finished perovskite, they did not find any phosphonic acid even in the samples to which it had been added. They did, however, find far fewer defects in the samples made with the additive. They concluded that it had slowed down crystallisation – producing larger grain size – before being expelled from the final crystal structure. This expelled phosphonic acid helped prevent recombination at defects and the fullerene contact.

The Swiss group’s cell, which was reported slightly earlier, has an efficiency of 31.25%. Chin says that, as with any with any laboratory technique, industry will decide whether the multi-step process used to produce the perovskite on a textured surface is industrially viable and notes that thermal evaporation is used to produce organic LEDs. ‘The most important part is that we were the first to break 30%, which has been kind of a psychological barrier for industry to decide whether the technology is worth pursuing in further research for commercialisation,’ he says.

‘Last year many groups were looking at each thinking “Who’s going to break this barrier first?” and now lots of groups are well above 30%,’ says materials scientist Stefaan De Wolf of King Abdullah University of Science and Technology in Saudi Arabia, whose group has achieved a certified efficiency of 33.7% in a tandem cell whose details await publication. He says that despite each cell comprising a perovskite on top of a silicon wafer ‘the way the device looks and the way it is processed is quite different’.

References

1 F Li et al, J. Am. Chem. Soc., 2020, 142, 20134 (DOI: 10.1021/jacs.0c09845)

2 S Mariotti et al, Science, 2023, DOI: 10.1126/science.adf5872

3 XY Chin et al, Science, 2023, DOI: 10.1126/science.adg0091

No comments yet