Cylindrical solar cells have better efficiencies throughout the day, independent of the angle of the sun

Scientists in china have manufactured cylindrical dye-sensitised solar cells (DSSCs) capable of generating a stable electrical output at different times of the day. Compared to their traditional flat counterparts, if correctly positioned so that the sun moves around their axis, their output is far less dependent of the angle of the sun.

The International Energy Agency predicts that by 2050 solar power could meet up to 16% of global energy demand. Photovoltaic cells are a key element of this vision and come in several different types, though they share common challenges such as efficiency, stability, cost and manufacture without the use of toxic or rare materials.

DSSCs are thin film solar cells that are easy to make, cheap, lightweight and have varying degrees of flexibility and transparency. They have a lower efficiency than some other types of thin film solar cell, compensated for by their low cost, which makes them ideal for smaller applications, such as rooftops and portable electronics. A major disadvantage of the DSSC is its reliance on a liquid electrolyte, requiring careful sealing around the edges of a flat DSSC panel. Higher temperatures can lead to liquid expansion and seal failure, releasing the hazardous electrolyte and damaging the cell.

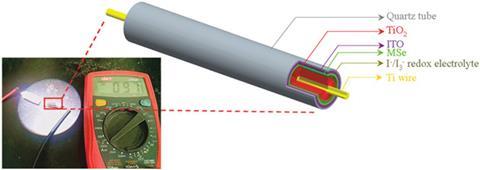

Qunwei Tang and co-workers at Ocean University of China, Qingdao, are experts at developing new materials for DSSCs. Inspired by a pendant lamp with hanging cylindrical rods as light diffusers; they designed and manufactured a cylindrical DSSC housed within a cheap, commercially available quartz tube. They first coated the inside of the quartz tube with the transparent conductor, indium tin oxide, followed by a transparent metal selenide counter electrode. Meanwhile a titanium nanowire supporting dye-loaded titania runs through the centre of the tube, serving as the anode. The void between the two is filled with liquid electrolyte and the ends of the tube are sealed with an ethylene vinyl acetate copolymer. This results in a far more stable cell than a flat DSSC panel where all four sides need to be sealed along their entire length.

‘The power conversion efficiencies of state-of-the-art solar cells with planar architectures are highly dependent of the incident angle of sunlight,’ says Tang. ‘Also sealing the electrolyte between two planar components is very difficult. Our design overcomes both of these problems which is significant.’

Ming He, an expert in polymer solar cells and DSSCs at Georgia Institute of Technology, US, thinks that the short lifetime of DSSCs in ambient conditions is a key factor limiting their commercial application. ‘This cylindrical architecture integrated with tube-shaped electrodes renders DSSCs with excellent resistance to electrolyte leakage and eventually leads to long-term stability.’

Tang and co-workers are now optimising their design and plan to extend it to perovskite solar cells, to protect them from moisture-induced degradation.

References

This article is free to access until 22 March 2016

Q Tang et al, Chem. Commun., 2016, DOI: 10.1039/c5cc10105k

No comments yet