Yfke Hager takes a look at the growth in green chemistry jobs and talks to the chemists whose research doesn’t cost the Earth

All over the world, companies are realising that what’s good for the planet is also good for business. Reducing waste buoys the balance sheets, and consumers and employees alike recognise the importance of reducing companies’ environmental impact. As industry and academia seek greener processes and technologies, opportunities abound for chemists.

When William Hesketh Lever first introduced Sunlight Soap in the 1890s, part of his vision was ‘to make cleanliness commonplace’. His company, Lever Brothers, went on to become one of the founding companies of Unilever, with a mission to clean up the world. Today, Unilever remains true to Lever’s principles, but cleanliness now applies across the business: to processes, as well as products. Under its Sustainable Living Plan, Unilever is committed to achieving three goals by 2020: to help more than one billion people take action to improve their health and well-being; to halve the environmental footprint of the making and use of its products; and to obtain all of its agricultural raw materials from sustainable sources.

‘It’s an ambitious plan,’ says Paul Jenkins, research director for structural materials and process science at Unilever, ‘but it will support the needs of consumers now and many generations into the future.’ He explains that chemists working at Port Sunlight, the company’s historic base near Liverpool, UK, are exploring ways to create useful building blocks from biowaste rather than using petrochemical-derived ingredients. ‘As an example, polymers are often used as thickeners for low-fat mayonnaise,’ says Jenkins. ‘But we have replaced polymers with citrus fibre from waste orange and lemon peel that would otherwise go to landfill.’

Leading by example

According to James Clark, director of the Green Chemistry Centre of Excellence at the University of York, UK, large companies like Unilever play a critical role in the development of sustainable technologies. ‘Large companies rely on upstream providers for the bulk of their raw materials,’ he notes. ‘And, due to their size, it’s vital that these companies lead the way by encouraging their providers to obtain these resources more sustainably.’ Clark believes that two driving forces for sustainability will become important in the near future. ‘First, new techniques will need to be developed for salvaging valuable resources from waste,’ he says. ‘And second, we need to start designing products in a way that enables us to recover valuable components more easily at the end of the product’s life.’

Across the pond, scientists at companies and governmental institutes are already rising to that challenge. The US Environmental Protection Agency Green Chemistry Challenge Awards recognise advances in sustainable technologies. Buckman International won this year’s Designing Greener Chemicals Award. The company has a long history of sustainability research, says Philip Hoekstra, technical director in Buckman’s research department. ‘The company was founded around 60 years ago, but even then it looked to replace the chemistry used at that time with something safer and better for the environment,’ he says. The award was for using enzymes to increase the number of fibrils that bind wood fibres together, resulting in stronger paper without the need for additional chemicals or energy. ‘Enzymes really fit the bill for sustainable technology,’ says Hoekstra. ‘They’re safe for workers to use and aren’t derived from petroleum-based materials.’

As a business strategy, Buckman’s greener process sets them apart from the competition, but Hoekstra adds ‘we also wanted to be good stewards of the environment. The drive for sustainability fell out naturally from that’. In pharma, there is also a strong business case for sustainable development, says AstraZeneca’s Louis Diorazio, a principal scientist who leads the company’s green chemistry network.

Together, we are pushing the boundaries of what is scientifically feasible

‘Externally, customers like to see companies actively reducing waste and their impact on the environment. From an internal perspective, working sustainably helps to drive down costs. The most expensive part of any process is often also associated with the greatest waste and environmental impact.’

Hoekstra agrees that it makes sense to follow the money: Buckman’s award-winning process allows papermaking with less wood fibre and higher percentages of recycled paper, resulting in significant cost savings. ‘Sustainable technology is like a three-legged stool,’ says Hoekstra. ‘It has to be safe for people, safe for the environment and profitable.’

A focus on green chemistry also fuels scientific advances. ‘As scientific challenges go, sustainability is a pretty good one,’ says Diorazio. ‘Designing an optimal process is a stimulating challenge that really drives innovation within the company.’ And that can help a company attract and develop the best scientists, he adds. Many areas of expertise are required to develop sustainable processes; the green chemistry network at AstraZeneca sees environmental specialists, pharmaceutical development chemists, chemical engineers and medicinal chemists all working together to improve drug manufacturing. ‘You’ve got to enjoy solving problems and discovering new science,’ says Diorazio.

Learning on the job

The first requirement for a career in sustainable chemistry, says Hoekstra, is that you have to be a good chemist. ‘We can teach the green part to those who are new to industry,’ he says, ‘as long as they know what they are doing from a chemistry perspective.’ Jenkins concurs that expertise in synthetic chemistry is essential, but he adds ‘our chemists also need to have an understanding of biology, since they work on biologically derived materials, and chemical synthesis may not always be the best route to a product’. Being able to work collaboratively is another asset. ‘Chemists need to work in an interdisciplinary space alongside people with different skill sets to deliver the best product to consumers,’ says Jenkins.

Most industries offer on-the-job training to develop their employees’ sustainable chemistry skills and awareness. ‘All our pharmaceutical development scientists are offered training in sustainable chemistry, and green chemistry is actively promoted within the company,’ says Diorazio. ‘For example, we are encouraged to use a solvent selection guide that highlights the environmental impact of each solvent, to help our scientists pick the one that is most sustainable and compatible with their chemistry.’ Similarly, at Unilever an R&D academy provides scientific and professional development.

Green, green grads

As interest in green chemistry grows, academic courses specifically tailored to sustainable chemistry are increasing in number. One of the first was the MSc in green chemistry and sustainable industrial technology at the University of York, which started a decade ago. ‘When the Green Chemistry Centre was set up as a hub for sustainable chemistry, it occurred to us that there was a training gap,’ explains Clark, who is the course director. Encouragement followed in the form of a grant from the Engineering and Physical Sciences Research Council and industry funding from GlaxoSmithKline and BP, and the MSc was born.

‘We saw a growing need for green chemistry skills across a range of industries,’ says Clark, ‘and this is reflected in the career paths of our graduates, who have gone on to careers at environmental consultancies, environmental protection agencies and even retail companies, where they measure the environmental footprints of products.’ The one-year course consists of lectures, workshops and seminars covering the principles, application and commercialisation of green chemistry, and a six-month industrial research project.

‘Collaboration with industry is a key component of the course,’ says Clark. He points to the Chem21 project as an example of the way collaborations will shape the future of sustainable chemistry. Initiated in October 2012, Chem21 will see leading academics working in green chemistry at 10 universities pairing up with scientists at six pharmaceutical companies to generate sustainable pharmaceutical manufacturing techniques. The project will investigate reducing solvent volumes, designing catalysts based on common rather than precious metals and devising new, greener routes to pharmaceutical ingredients. ‘This is a good example of the way things are heading,’ says Clark.

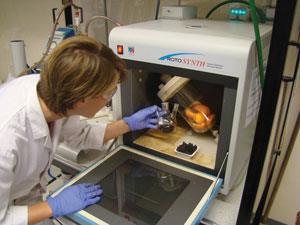

Other collaborations between academia and industry are already starting to bear fruit. The University of Liverpool, Unilever and sugar producer AB Sugar recently joined forces to establish a micro-biorefinery at the Centre for Materials Discovery at The University of Liverpool. The aim of the collaboration is to derive polymer building blocks from renewable biomass feedstocks. ‘Working alongside university scientists offers great opportunities for our chemists,’ says Jenkins. ‘Together, they are pushing the boundaries of what is scientifically feasible.’

No comments yet