Self-healing coatings inspire improvements to the electrodes

Laura Howes /Washington, DC, US

Capsules coated onto electrodes could mitigate potential problems with lithium ion batteries by turning the batteries off when they overheat and ’healing’ the electrodes when they crack and degrade, according to a researcher in the US.

Scott White from the University of Illinois at Urbana-Champaign says that in his lab self-healing materials have inspired a new concept for battery safety and self-repair.

Lithium ion batteries are already common in portable electronic applications, such as mobile phones, where their high energy density sets them apart from alternatives. And they are likely to become even more widely used as electric and hybrid cars grow in popularity. But they have some drawbacks. Most worryingly perhaps for consumers, the batteries can overheat and catch fire or explode.

Another problem is the longevity of the batteries - the anode is degraded by successive rounds of lithium deposition and removal, and eventually the battery simply stops working.

White says coating the electrodes with capsules could help in both cases.

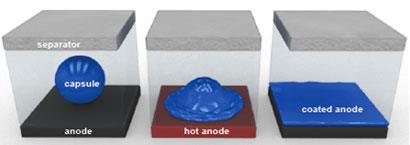

His solution to the safety problem involves capsules made of a surprisingly simple material: polyethylene. If the battery heats up 105?C, the capsules melt and the polyethylene covers the electrode, halting ion conduction and thereby shutting down the battery.

His solution to the longevity problem is capsules that release ’healing’ fluid. In this case, the capsules are more like eggs, with a brittle shell containing a liquid centre, a gallium-indium alloy. The same process that degrades the electrode shell causes the shell to crack, and this releases the liquid metal, which coats the anode and restores its function almost instantaneously.

According to White, both these approaches could be integrated into the manufacture of batteries and would not add significantly to the cost. In addition, his work might be applied to other battery systems. ’This is a translatable technology that can be modified,’ he adds.

No comments yet