The forgotten innovator whose work led to the Quickfit trademark

The flask is equipped with a mechanical stirrer, possibly one of Hershberg’s (Chemistry World, May 2011, p60), which are seldom seen in small-scale synthetic labs these days. The glass stirring rod passes through a mercury seal. But most striking of all is the absence of ground glass. All of the connexions are made through rubber bungs that Levy must have laboriously drilled using a cork borer (Chemistry World, March 2008, p81). That the photograph was taken a few years after the second world war is a testament to the slow spread of standard ground glass joints that had then existed in Britain for over 30 years.

My colleague Alwyn Davies, one of Levy’s contemporaries who came to University College London as an undergraduate in 1944, does not remember using ‘Quickfit’ glassware until much later. ‘It was too expensive,’ he says. But could its slow adoption also have been a reflection of a certain conservatism? ‘Why should we spend money on this new stuff when we got on just fine with the old?’

Interchangeable ground glass joints had been around since about 1915, when they were introduced in the UK by the firm of WG Flaig (Chemistry World, December 2019, p68). By the late 1920s standards for the joints were being introduced across Europe and the US as more and more synthetic chemistry was being done not only in universities but also in industrial research and product development labs. One such firm was Triplex Safety Glass, Britain’s leading manufacturer of laminated safety glass, crucial as car crashes rose in step with vehicle sales. The company had research labs next to its main factory in King’s Norton on the outskirts of Birmingham. One of its employees would change British scientific glassware forever.

Leslie Vivian Donald Scorah was born in Barnsley on 9 June 1902. His father was a coal merchant, and the family lived in a typical small terraced house not far from the centre of town. Scorah studied chemistry at Sheffield and did a Master’s project on the synthesis of six-membered rings containing sulfur with the organic chemist George Macdonald Bennett in around 1925. After Scorah graduated he was hired by the National Physical Laboratory in Teddington. He didn’t spend much time there.

In May 1929 Scorah started as assistant chemist at Triplex. The main thrust of his work was to develop better adhesive polymers for use in laminated glass. In 1932, Scorah’s supervisor, John Wilson, asked him to find a way to make acrylic acid. Scorah made significant progress and informed his boss, who passed on the information to the Board, suggesting that the work be patented. The Board ignored this while Scorah continued to work on the problem, exploring acrylate esters and their polymerisation.

All of Scorah’s work involved organic synthesis so he must have been acutely aware of the hassle of using corks and bungs to connect glassware together. Could it be that Wilson and Scorah devised the project to make standard joints? Or did Triplex’s director Leslie Cunningham spot the opportunity, as company histories suggest?

We may never know, but in 1933, Scorah and Triplex filed four patents describing methods to make interchangeable conical joints for glassware. As Scorah wrote in one of the patents, grinding stoppers individually was tedious and often gave poor results. Instead Scorah proposed making conical joints on a lathe, adopting the 1:10 taper relative to the diameter that became the British standard in the same year. This meant making the joint first using a mandrel (for sockets) or mould (for cones), and then grinding in a second stage. By making the basic shape with sufficient precision, the grinding process would need to take off no more than three thousandths of an inch from the glass. The process could be done directly on an existing flask or with pieces of glass tubing.

In another patent, Scorah argued that existing stoppers were a pain. Typically made with a flat key-like end, the sealing surfaces invariably picked up contamination when the stopper was set aside on the bench. He proposed a stopper that could be set on its end to keep the ground glass section clean. We have hundreds of these elegant stoppers in our drawers and yes, we stand still them on their ends.

Triplex’s boss Cunningham was quick to recognise the value of these ideas. By the time the patents had been confirmed, a trademark was registered: Quickfit, its logo a double-walled stylised letter Q. A new subsidiary company, Quickfit and Quartz, was established to supply the burgeoning laboratory glassware market. The business took off, and would later become part of a new venture (QVF), making industrial pipelines with subsidiaries across Europe. The drains of my own chemistry building, erected in 1970, were assembled entirely out of QVF borosilicate pipe.

Yet just as Quickfit and Quartz got going, on 30 April 1934, Scorah left Triplex. Was this related to Quickfit? Was he miffed that he had been sidelined from exploiting his invention? Or was he just bored?

Whatever were the reasons, he set up his own scientific supplies company with a workshop at the back of his house, across the tracks from Triplex. In the 1950s his second cousins, Norma and David Stevenson, then aged five and 10 years old, visited the house with its high gable above the entrance and stained glass in the windows. They remember a cluttered workshop with benches and long windows, almost like a conservatory, where Scorah demonstrated some glassblowing.

In 1935 there is a brief mention of Scorah attending the Chemical Society meeting in Birmingham to exhibit ‘a large number of pieces of laboratory apparatus of his own manufacture, having standard, interchangeable ground-glass joints.’ No doubt he made his own joints as the one image I have seen of LVM Scorah glassware has no logo, only his name. One wonders how he imagined being able to compete with a giant like Quickfit and Quartz. Relations with his former employer were in any case about to sour.

Scorah had signed a confidentiality agreement six months after he started working at Triplex, which assigned to his employer all the intellectual property he developed while working for the firm. Despite this, in 1935 Scorah filed a patent relating to acrylic acid. When Triplex realised the importance of the method, it sued. The case has entered the annals of employment law. The prosecution argued that the work had been done when he had been employed in Triplex’s labs, and he was duty bound to hand over the intellectual property. The defence countered that Scorah had done everything by the book. He had reported his work, suggested that the patent be registered, but Triplex hadn’t bothered. He was now an independent businessman entitled to profit from his invention.

The ruling was very carefully worded. Yes, there was a duty to allow individuals to use the fruits of their labour, but equally ‘no employee is entitled to filch his employer’s property, in whatever form that property may be’. Scorah lost. The judge awarded the company the patent but did not impose punitive damages, adding ‘I have seen the Defendant in the witness-box. He is, I have no doubt, a person of skill and knowledge in his own profession, but obviously he is not a person of skill and knowledge in the law.’

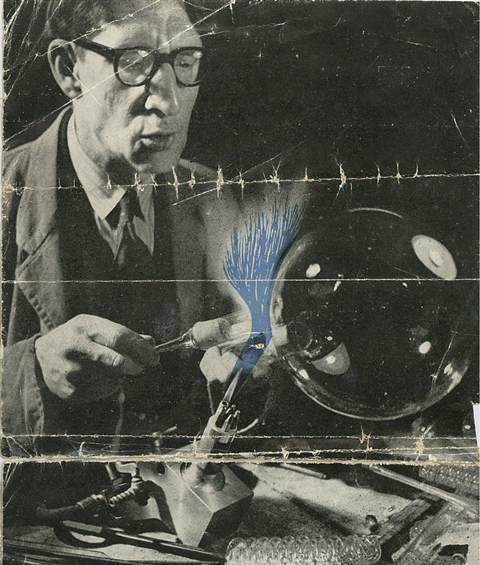

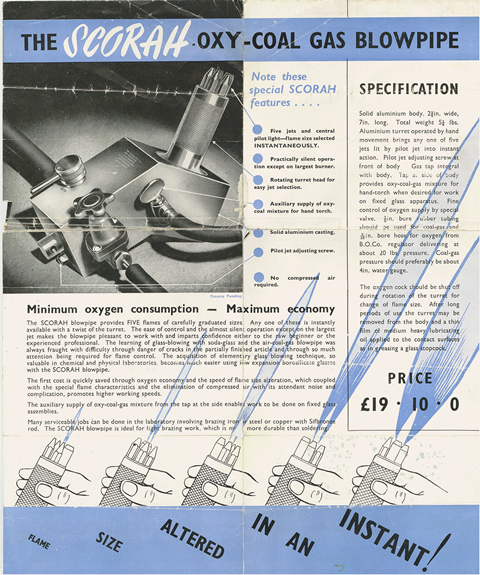

From then on Scorah minded his own business, patenting from time to time, but only in relation to glassblowing. In 1949 he patented a new form of glassblowing torch, a turret burner, with five separate nozzles arranged in a circle around a central pilot light. The size of the flame could be controlled by rotating a collar to bring different nozzles into position.

When Jim Huckfield, a young glassblower, was asked to set up a workshop for Birmingham’s Chemical Engineering Department in 1958, he chose a Scorah burner. He headed to King’s Norton to collect it. He remembers the door being opened by an old lady, probably Marion, Scorah’s sister. The office was a mess of papers and the workshop at the back of the house was a bit shambolic. To Huckfield, Scorah seemed ancient, hunched and eccentric (though he would only have been in his 50s), and asked myriad questions before finally deciding that the young man was worthy of owning a Scorah torch. But when Huckfield strapped the heavy burner to the back of his motorcycle, Scorah became quite agitated. Only when Huckfield convinced him that the burner would be safe did Scorah relent.

Scorah never married and died in 1982, still living at the same house he shared with his sister (he’d also bought the house next door for them and his mother in 1945). His probate record suggested that he had profited little or not at all from Quickfit. The houses were sold after Marion’s death in 1995. What happened to the workshop? The owners of the handsome but decaying Victorian house have not replied to enquiries.

Few of us really notice the Quickfit trademark that sits on the side of much of our glassware. Quickfit and Quartz, like many other legendary firms, was eventually absorbed into SciLabWare as part of the endless mergers and acquisitions that have ‘rationalised’ the British laboratory equipment industry. Scorah, in spite of his enormous impact, has been forgotten. But his joints are an invention so influential and so widely recognised that perhaps a campaign should be started to get a blue plaque erected at his old home and workshop in King’s Norton.

I have just one favour to ask. If you happen to find a Scorah burner in an attic, could I have it? Or even a set of cork borers. They’ll have a good home.

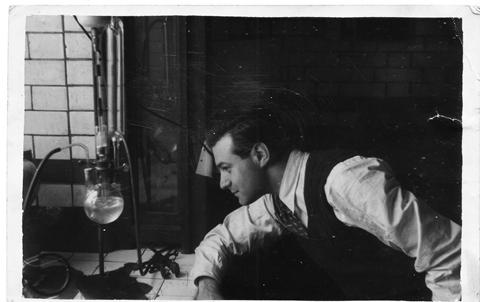

A few years ago, one of my department’s alumni, Isidore Levy, gave me a photograph dating from his PhD work around 1949. The photograph shows a handsome young man, in shirtsleeves, wearing a tie and a waistcoat, leaning with his forearm on the edge of a tiled fumehood, starting intently at a reaction. If the absence of safety glasses grabs your attention, it is the glassware that is at once strangely familiar, yet on close inspection, totally alien.

The three necked flask is equipped with a mechanical stirrer, possibly one of Hershberg’s, which are seldom seen in small-scale synthetic labs these days (I rescued one from a bin a few weeks ago). The glass stirring rod passes through a mercury seal. But most striking of all is the absence of ground glass. All of the connections are made through rubber bungs that Levy must have laboriously drilled using a cork borer. That the photograph was taken a few years after the second world war is a testament to the slow spread of standard ground glass joints that had existed in Britain for over 30 years.

My colleague Alwyn Davies, one of Levy’s contemporaries who came to University College London as an undergraduate in 1944, does not remember using ‘Quickfit’ glassware until much later. ‘It was too expensive,’ he says. But could its slow adoption also have been a reflection of a certain conservatism? ‘Why should we spend money on this new stuff when we got on just fine with the old?’

Interchangeable ground glass joints had been around since about 1915, when they were introduced in the UK by the firm of W G Flaig. By the late 1920s standards for the joints were being introduced across Europe and the US as more and more synthetic chemistry was being done not only in universities but also in industrial research and product development labs. One such firm was Triplex Safety Glass. Riding on the wave of the growing automotive market, Triplex was Britain’s leading manufacturer of laminated safety glass, crucial as car crashes rose in step with vehicle sales. Triplex had formed a joint venture with glassmaker Pilkington, and sales were expanding rapidly. The company had research labs next to its main factory in King’s Norton on the outskirts of Birmingham. One of its employees would change British scientific glassware forever.

Northern light

Leslie Vivian Donald Scorah was born in Barnsley in Yorkshire, UK on 9 June 1902. His father was a coal merchant, and the family lived in a typical small terraced house not far from the centre of town. Scorah studied chemistry at Sheffield and did a Master’s project on the synthesis of six-membered rings containing sulfur with the organic chemist George Macdonald Bennett around 1925. That Bennett recommended Scorah for associate membership of the Institute of Chemistry (the precursor to the Royal Society of Chemistry) suggests that Bennett rated him as chemist. After Scorah graduated he was hired by the National Physical Laboratory in Teddington. He didn’t spend much time there.

John Wilson, a fellow graduate of Sheffield who had been decorated for bravery in the first world war, lured Scorah back North. In May 1929 Scorah started as assistant chemist at Triplex with Wilson as his supervisor. The main thrust of his work was to develop better adhesive polymers for use in laminated glass. Scorah and Wilson developed new rubbery olefin/methacrylate copolymers to improve the adhesion of the safety film to the glass on either side. In 1932, Wilson asked Scorah to find a way to make acrylic acid. Scorah made significant progress and informed his boss, who passed on the information to the Board, suggesting that the work be patented. The Board ignored this while Scorah continued to work on the problem, exploring acrylate esters and their polymerisation.

Only connect

All of Scorah’s work involved organic synthesis so he must have been acutely aware of the hassle of using corks and bungs to connect glassware together. Could it be that Wilson and Scorah devised the project to make standard joints? Or did Triplex’s director Leslie Cunningham spot the opportunity, as company histories suggest?

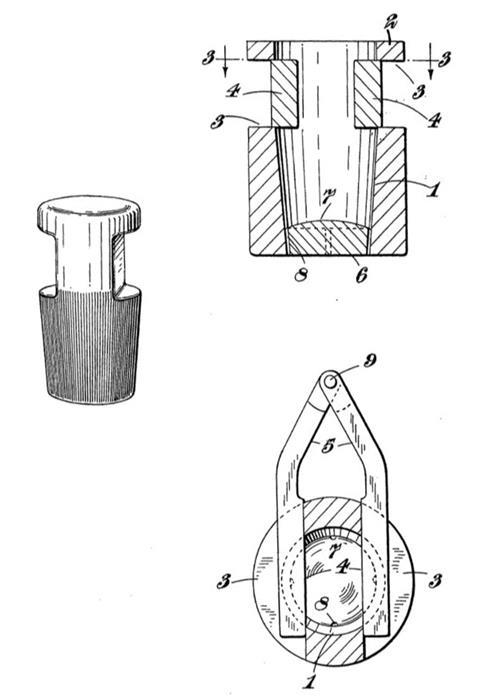

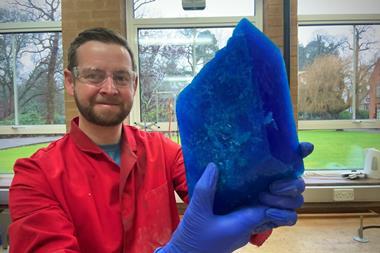

We may never know, but in 1933, Scorah and Triplex filed four patents describing methods to make interchangeable conical joints for glassware. As Scorah wrote in one of the patents, grinding stoppers individually was tedious and often gave poor results. Instead Scorah proposed making conical joints on a lathe, adopting the 1:10 taper relative to the diameter that became the British standard in the same year. This meant making the joint first using a mandrel (for sockets) or mould (for cones), and then grinding in a second stage. By making the basic shape with sufficient precision, the grinding process would need to take off no more than three thousandths of an inch from the glass. The process could be done directly on an existing flask or with pieces of glass tubing.

A diagram in the first patent shows the process in action. The neck of a round bottom flask, held in the jaws of a lathe, was spun and heated in a flame. A mandrel made from porous cast iron (better to hold the abrasive) was also heated, but rotated in the opposite direction, then pressed into the neck, producing the desired taper. After cooling, the mandrel would be wetted and coated with a little carborundum and the process repeated to generate the final surface.

In another patent, Scorah argued that existing stoppers were a pain. Typically made with a flat key-like end, the sealing surfaces invariably picked up contamination when the stopper was set aside on the bench. He proposed a stopper that could be set on its end, to keep the ground glass section clean. Thus a hollow stopper with a pair of flat faces could be made by dropping a gob of molten glass into a pre-heated one-piece mould that included a conical portion and a domed base; the molten gob was then blown into shape while held by a pair of ‘tongs’ to form a pair of parallel surfaces for the chemist to grip onto. Again, the final sealing surface would be ground in a second step. We have hundreds of these elegant stoppers in our drawers and yes, we stand still them on their ends to keep them clean.

The rise of Quickfit

Triplex’s boss Cunningham was quick to recognise the value of these ideas. By the time the patents had been confirmed, a trademark was registered: Quickfit, its logo a double-walled stylised letter Q. A new subsidiary company, Quickfit and Quartz, was established to supply the burgeoning laboratory glassware market. With a factory at Stone, near Stoke-on-Trent in Staffordshire, the firm used borosilicate glass produced either by Chance Brothers or by the Newcastle-based Jobling. Jobling held the licence for Corning’s Pyrex glass, which rivalled Schott’s Duran brand. The many ads taken out by Quickfit and Quartz in trade magazines through the 1950s have wonderful pictures of the factory and its facilities.

The business took off. By 1948, Arthur Vogel’s Practical Organic Chemistry devoted five pages to interchangeable joints, listing seven firms as suppliers of such glassware and adding that ‘if the merits of ground glass apparatus were more widely known … it would find a place in every laboratory’. For Vogel, there were many advantages: contamination by rubber was a problem, boring corks and bungs took time, ground glass joints were inert to corrosive liquids and vapours, apparatus could be assembled in a flash, interchangeability made for flexibility as well as ease of repair, and the joints eliminated narrow pinch points, making chemistry safer and distillation more consistent.

Quickfit and Quartz would later become part of a new venture (QVF), making industrial pipelines, QVF, with subsidiaries across Europe. The drains of my own chemistry building, erected in 1970, were assembled entirely out of QVF borosilicate pipe. But Scorah was not involved in the growth of the company, having left Triplex on 30 April 1934. Was this related to Quickfit? Was he miffed that he had been sidelined from exploiting his invention? Or was he just bored?

Whatever were the reasons, he set up his own scientific supplies company with a workshop at the back of his house, across the railway tracks from Triplex. In the 1950s his second cousins Norma and David Stevenson, then aged five and 10 years old, visited the house with its high gable above the entrance and stained glass in the windows. They remember a cluttered workshop with benches and long windows, almost like a conservatory, where Scorah demonstrated some glassblowing.

In 1935 there is a brief mention of Scorah attending the Chemical Society meeting in Birmingham to exhibit ‘a large number of pieces of laboratory apparatus of his own manufacture, having standard, interchangeable ground-glass joints.’ He avoided using Jobling’s Pyrex glass, choosing instead Phoenix borosilicate glass made by the British Heat Resisting Glass Company, a company now mostly remembered for its cookware. No doubt he made his own ground glass joints as the one image I have seen of LVM Scorah glassware (on sale on eBay) has no logo, only his name. One wonders how he imagined being able to compete with a giant like Quickfit and Quartz. Relations with his former employer were in any case about to sour.

Legal battle

Scorah had signed a confidentiality agreement six months after he started working at Triplex, which assigned to his employer all the intellectual property he developed while working for the firm. Despite this, in 1935 he filed a patent relating to acrylic acid. When Triplex realised the importance of the method, it sued. The case has entered the annals of employment law. The prosecution argued that the work had been done when he had been employed in Triplex’s labs. Under the terms of his contract of employment he was duty bound to hand over the intellectual property. The defence countered that Scorah had done everything by the book. He had reported his work and suggested that the patent be registered, but Triplex hadn’t bothered. He was now an independent businessman entitled to profit from his invention.

The ruling was very carefully worded. Yes, there was a duty to allow individuals to use the fruits of their labour, but equally ‘no employee is entitled to filch his employer’s property, in whatever form that property may be, whether it is in the form of a secret process or goodwill or in some other form.’ Scorah lost. The judge awarded the company the patent but did not impose punitive damages, adding ‘I have seen the Defendant in the witness-box. He is, I have no doubt, a person of skill and knowledge in his own profession, but obviously he is not a person of skill and knowledge in the law.’

Burning with ideas

Judging from the glassware I’ve seen Scorah must have been very skilled indeed. From then on he minded his own business, patenting from time to time, but only in relation to glassblowing. Grace’s Guide for 1951 makes reference to a tradename ‘Chemikano’, presumably a play on Meccano and the interconnectivity of his joints.

In 1949 he patented a new form of glassblowing torch, a turret burner, with five separate nozzles arranged in a circle around a central pilot light. The size of the flame could be controlled by rotating a collar to bring a different nozzles into position. His burner features in a 1978 textbook of Glassblowing for Laboratory Technicians. The glassblower Paul Le Pinnet used one when he was a trainee at Manchester University and fell in love with it. ‘The Scorah lamp consisted of a heavy aluminium block in which was what amounted to a large tapered key on which was mounted a series of jets. As you rotated the jets various holes within the block introduced gas or oxygen to the various jets. … The flame it produced using towns [sic] gas was a wonderfully slender laminar flow flame which seemed to lick around the glass.’ Above all it was almost completely silent, in contrast to the ‘cannon-burners’ that Le Pinnet had used previously.

The torch was a game-changer. When Jim Huckfield, a young glassblower, was asked to set up a workshop for Birmingham’s Chemical Engineering Department in 1958, he chose a Scorah burner. He headed to King’s Norton to collect it. He remembers the door being opened by an old lady, probably Marion, Scorah’s sister. The office was a mess of papers and the workshop at the back of the house was a bit shambolic. To Huckfield Scorah seemed ancient, hunched and eccentric (though he would only have been in his 50s), and asked myriad questions before finally deciding that the young man was worthy of owning a Scorah torch. But when Huckfield strapped the heavy burner to the back of his motorcycle, Scorah became quite agitated. Only when Huckfield convinced him that the burner would be safe did Scorah relent.

Scorah’s Oxy-Coal Gas Blowpipe persisted until the arrival of North Sea gas when rival torches designed for the new fuel were sold by Jencons, Jennings and other suppliers. I have a Jencons torch in my lab. Our glassblower uses Jennings’.

A forgotten legacy

Scorah never married and died in 1982, still living at the same house he shared with his sister (he’d also bought the house next door for them and his mother). His probate record suggested that he had profited little or not at all from Quickfit. The houses were sold after Marion’s death in 1995. What happened to the workshop? The owners of the handsome but decaying Victorian house have not replied to enquiries.

But Quickfit had taken on a life of its own. The British Standard of 1934 for the cones and sockets was revised in 1950 and again in 1972. There were four series A to D, of which the B series is the one most commonly seen in labs today, the familiar B10, B14, B19, B24 etc., the other series differing in the lengths of the joints. The specifications in different countries have gradually converged, the joints being described by the diameter of the widest part of the cone, followed by the length of the ground section: 24/40 is 40 mm long, 24 mm across.

Few of us really notice the Quickfit trademark that sits on the side of much of our glassware. The words ‘Made in England’ have vanished, a sign of the times. And Quickfit and Quartz, like many other legendary firms, was eventually absorbed into SciLabWare as part of the endless mergers and acquisitions that have ‘rationalised’ the British laboratory equipment industry. Scorah, in spite of his enormous impact, has been forgotten. But his joints are an invention so influential and so widely recognised that a perhaps a campaign should be started to get a blue plaque erected at his old home and workshop in King’s Norton.

I have just one favour to ask. If you happen to find a Scorah burner in an attic, could I have it? Or even a set of cork borers. They’ll have a good home.

Acknowledgements

I am hugely indebted to Alan Gall (Archivist, Institute of Science & Technology, Sheffield), for advice and for putting me in contact with LDV Scorah’s family – David Stevenson, Norma Hyde (née Stevenson) and Hilary and Ian Firth – who shared the brochure and other memorabilia. Paul Le Pinnet and Jim Huckfield shared memories of using the blowpipe. David Allan of the RSC Library unearthed details of Scorah’s early career. And glassblowers John Cowley, Reece Bramley and Ian Pearson (BSSG) provided leads, references and ideas.

The story of Quickfit, part one: Friedrich's joints

In the first article in a special Classic Kit series on Quickfit, Andrea Sella tracks the origin of standardised ground glass joints to 1900s Prussia

- 1

- 2

Currently

reading

Currently

reading

Scorah’s Quickfit

No comments yet