When a consumer buys an item, they expect it to contain precisely what is stated on the label. As such, the quality control measures that ensure that expectation is met permeate all of our lives. A quality error can lead to major concerns for customers – whether a peanut allergen goes undetected in a foodstuff, or the purity of a chemical is inaccurately defined. This also applies to impurity reference standards, which are used to test for the presence of impurities in a substance.

In a pharmaceutical context, if the identity, purity or specification of an impurity reference standard is not correctly defined, it could compromise the safety of product manufacturing downstream. Even in small quantities, drug contamination can have a negative impact on drug efficacy or patient health. Similarly, quality-related issues in research could completely invalidate scientific findings. In both cases it can lead to incorrect conclusions, at the very least wasting a customer’s time and money, and ultimately damaging trust.

Toronto Research Chemicals (TRC) is a world leader in manufacturing complex organic chemicals for the biomedical industry, including impurity reference standards. In this article, we delve into TRC’s approach to problem solving and quality control for the production of reliable impurity reference standards, and the importance of science for a safer world.

Collaborating to deliver a reliable product

Bringing a high-quality impurity reference standard to a customer is very much a team effort. Initially, the planning team will investigate synthetic routes for a molecule, while the production team is responsible for manufacturing. Then, once synthetic chemists have settled on a synthesis method that yields the correct compound at the desired purity, the analytical team conduct identity and purity tests to verify the findings. It doesn’t end there. At TRC, the quality assurance (QA) team then analyses the data, comparing with known information in the literature and applying their own experience and expertise. This helps to ensure that the identity and purity of the compound are truly what they are supposed to be.

Collaboration is the cornerstone of chemical production, and this is even more true when confronting unusual situations or particularly challenging cases.

Obstacles in impurity reference standard production

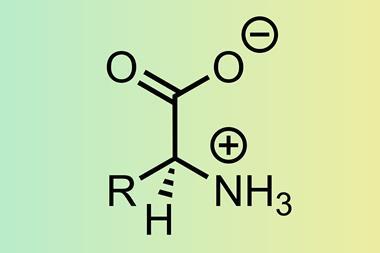

A chemical supplier faces numerous challenges. For example, TRC has an extremely diverse catalogue, with upwards of 150,000 molecules that are used in many areas of industry and research. These range from simple, stable small molecules to complex, unstable macrocycles. For known compounds with adequate scientific literature already in place, the process is simpler. For unknown compounds, chemists are in uncharted territory and so must investigate the structure to determine whether, for example, the chemical is moisture- or light-sensitive, and take appropriate steps for handling it accordingly. If moisture-sensitive, it will need to be handled in a chemically inert environment, such as in an atmosphere of argon or nitrogen gas.

If the structure is uncertain and there is no supporting literature to help, the team will need to devise tests to confirm the chemical structure and other relevant characteristics, such as purity. This requires highly skilled employees and it is for this reason that TRC analytical and QA teams have a strong grounding in organic chemistry.

The toolkit for chemical problem solving

A standard ‘menu’ of testing at TRC includes proton nuclear magnetic resonance (1 H NMR) spectroscopy, mass spectrometry and Fourier transform infrared spectroscopy (FT-IR) to help assign structure. Specific rotation or chiral high-performance liquid chromatography (HPLC) help to determine stereochemistry as needed. Subsequently, HPLC or gas chromatography (GC) and elemental analysis can help to determine chemical purity.

Additional tests may be conducted to provide further verification of the identity or purity of materials. Even if the techniques have little reference to the majority of TRC’s catalogue, as part of TRC’s dedication to quality the company is always willing to add additional techniques and equipment to its facility. For example, thermogravimetric analysis (TGA) can help determine the volatile components present by monitoring the weight change, and in some cases x-ray crystallography can help to determine the atomic and molecular structure of a chemical. Thorough testing and a willingness from the analytical team to adapt and apply new methodologies are key to ensuring the quality of material delivered to customers.

Key qualities for a reference standard supplier

Transparency and willingness to take extra steps to ascertain that the material is correctly defined are key attributes for a chemical supplier. Not every customer requires 99.9% pure material, but the purity must be accurately represented. In addition, a Certificate of Analysis (CoA) detailing the tests performed, as well as the purity information, is as much a product as the chemical, and is something that should be sought out. After-sales support is another key service – helping customers to work out any issues they may have and allay concerns. Robust SOPs and a strong quality management system (QMS) are also desirable. TRC believed these were in place, and actively pursued and succeeded in recently becoming ISO 9001 certified, validating their assumption of being a company with the proper processes, policies and documentation in place.

Going the extra mile

Chemistry is full of surprises, and not all of them are pleasant. That’s why in addition to looking for experience, certifications and transparency, a customer should search out a supplier willing to go above and beyond. For example, at TRC chemists recertificate material as needed. Even months after delivery, if they find that the material has degraded, TRC chemists take professional pride in performing their duty of informing the customer.

In one case, the team at TRC manufactured a compound that had little to no supporting literature or data available. In theory, there were three possibilities for the final structure according to the synthetic route. As these were almost indistinguishable regioisomers of each other, 1 H NMR, mass spectrometry and elemental analysis yielded almost identical results. To overcome this problem, the analytical team turned to its NMR experts, who devised a specialised 15 N NMR technique. Using this technique, the QA team was able to rule out two of the three potential structures, and verify that there was no need for concern before releasing it to the customer.

Bringing it together: a dedicated team of chemical problem solvers

A wide array of expertise, skills and equipment is necessary to maintain TRC’s approach to quality in chemical synthesis. However, these are not the only ingredients for success: the dedication of the team is the deciding factor. A strong knowledge base and an openness to learn are vital. In some cases, the team takes on extremely difficult projects which can turn into time-intensive labours of love so the passion and skills the team acquires from these types of projects are hugely beneficial in the long run. Supported by a steadfast team of chemists, the value of this rigorous approach to quality control is clear to customers. By partnering with a reliable supplier well equipped to proactively solve problems in the chemical space, the industry can rest assured that their impurity reference standards do not introduce potentially disastrous inaccuracies into their processes. It is science at its best, working to ensure a safer world.

XueJing Zheng - Analytical chemistry manager, TRC

XueJing has a BSc in Organic Chemistry, and a MSc in water science analytical chemistry. She has 15 years of experience in pharmaceutical chemistry analysis and chemical analysis. She joined in TRC-LGC in 2009 and her current role is Analytical chemistry manager, responsible for testing TRC’s chemical materials.

Toni Rantanen - Quality manager, TRC

Born in Finland, Toni found his passion for science in high school and gravitated towards synthetic chemistry, lured by interesting smells, explosions and colours. He obtained his MSc degree from the University of Helsinki and performed the experimental part of his MSc thesis with Prof. Henning Hopf at TU Braunschweig (Germany). Toni returned to Germany for his PhD studies with Prof. Carsten Bolm at RWTH Aachen. Afterwards, in 2007 he landed in Canada for postdoctoral studies with Prof. Victor Snieckus at Queen’s University in Kingston.

Toni joined Toronto Research Chemicals in 2014 as a synthetic chemist. In 2015 he took on a role as a lab supervisor, and subsequently in 2019 he stepped into the shoes of quality manager. Despite 15+ years of experience in the field, interesting chemistry as well as working for a company that is constantly evolving continue to motivate him. Toni’s talented direct reports have learned to love and hate his favourite questions of ’why?’ and ’what do you think?’.

When not problem-solving, Toni enjoys camping, badminton, kayaking and adventuring with his wife. He also enjoys cooking, which is just like synthetic chemistry, only you get to eat the results!

No comments yet