Personalised medicines are revolutionising the pharmaceutical industry, offering more targeted therapeutics to patients in need. Arcinova is integrating digitalisation with flow chemistry to enhance and expedite their manufacture

Medicines manufacturing is going through a remarkable revolution driven by the targeting of rare diseases that affect perhaps less than 200,000 patients worldwide. Variation in genetic make-up and environmental influences mean that blockbuster, one-size-fits-all medicines may be more effective for some individuals than others. The increased stratification of more widespread diseases is generating the need for personalised medicines in sub-populations of patients.

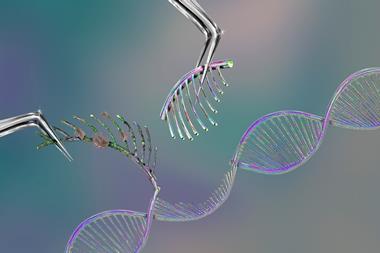

This is especially true with regard to some of the most complex diseases, such as cancer. For example, studies on the genetic makeup of breast cancer patients found that around 5–10% exhibited a mutation in the BRCA1 and BRCA2 gene, putting them at higher risk of developing breast and ovarian cancer.1 In 2018, the FDA approved the first treatment specifically for breast cancer patients with inherited BRCA1 and BRCA2 gene mutations. As research advances, there is a growing demand for more personalised medicines that are specifically designed to target small patient populations that possess defined biomarkers.

as a stand-alone solution, flow chemistry seems like the answer to the problem of manufacturing personalised medicines

To prepare for this imminent revolution in pharmaceutical development, manufacturing production must be refined to increase efficiency. Fortunately, as the industry moves towards its data-driven fourth revolution – Chemistry 4.0 – chemists are increasingly taking advantage of the wealth of digital tools available to control and inform reactions in a way that optimises the outcome.

A personal problem

Genetic variation and environmental factors determine the usage of personalised medicines. This means that their distribution is often location-specific and that they need to be manufactured in far smaller batches than mainstream therapeutics. In addition, targeted pharmaceutical treatments often require highly potent small-molecule drug substances. As a consequence, the amount of drug substance required for a personalised drug candidate has reduced significantly. This, alongside the increasing complexity of new drug substances generally, has led to increased demands on chemical manufacture. In order to respond to these challenges, pharmaceutical manufacturers are looking at innovative technologies to enhance processes and increase efficiency.

Going with the flow

One way in which pharmaceutical manufacturers can enhance the production of personalised medicines is with flow chemistry. In contrast to traditional batch processing, flow chemistry uses a single reactor system into which the starting materials flow and each product becomes a reactant for the next stage of the process. This can increase the safety and efficiency of drug manufacture, as smaller reaction volumes mean that it is easier to control and monitor the progress of a reaction. This is also an advantage if the intermediate compounds are unstable, which can often be the case when dealing with more potent and complex therapeutics.

As a stand-alone solution, flow chemistry seems like the answer to the problem of manufacturing personalised medicines. However, for flow chemistry to reach its full potential and aid the transformation of the industry to supply complex and targeted drugs in smaller quantities, digitalisation also needs to be embraced. That is why contract development and manufacturing organisations (CDMOs), such as Arcinova, have looked at implementing this philosophy to enhance flow chemistry, increasing the efficiency of drug substance development and expediting the production of personalised medicines.

The revolution will be digitalised

Digital technologies have a lot to offer the pharmaceutical industry. With the more repetitive tasks taken over by automation and computational technologies, chemists are left with more time to continue solving problems in the field. Recent innovations in this area are focused on improving process performance and control.

Design of experiments process optimisation

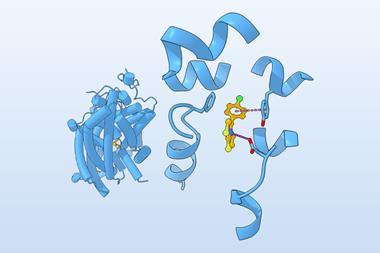

Computer modelling not only derives unbiased correlations and analysis of results but also helps to identify the fastest and most effective pathway for a reaction to follow. The statistical approach, known as design of experiments (DoE), is the process of generating and testing a reaction model by understanding the mathematical relationship between process inputs and outputs. As mathematics and statistics have evolved, it is now possible to use algorithms to provide the same model of the best reaction pathway using fewer experiments. This has enabled rapid understanding of processes and ultimately increased efficiency in the field.

Process analytical technologies (PAT)

The algorithms used for DoE have also prompted the development of automated reaction equipment. Process analytical technologies (PAT) have been used in pharmaceutical and chemical industries to monitor reaction progress in real-time, feeding the data back to a computer that can analyse the outcome. One example of this is Fourier-transform infrared (FT-IR) spectroscopy probes within the reactor. These instruments collect live data on the temperature, pressure and concentration of reagents needed to optimise the current reaction. This provides manufacturers with evolving data that they can use to confirm the progression of the reaction and increase overall confidence in the final outcome.

Feedback loops

Advancements in DoE and the use of automated reaction equipment tie neatly together into the concept of experimental feedback loops. These loops optimise reactions over time by automatically changing conditions as the reagents flow through the reactor. By continually learning from experimental data, feedback loops can search through the process space, optimising for the yield, purity and, increasingly, the environmental sustainability of the final product.

A winning formula

Arcinova is already implementing these technologies through their award-winning Flowinova Project. In collaboration with a team of researchers from the University of Nottingham, the project has primarily focused on how continuous flow manufacture can be used to perform certain chemical reactions at scale. Automation and feedback loop technology have also allowed for reactions to be optimised in real time, rapidly providing therapeutics at a higher purity and therefore expediting their time-to-market. Through the implementation of digitalised tools, the Flowinova project has successfully shown that it’s possible to carry out the manufacture of complex, targeted medicines in quantities that are much better suited to the demands for personalised medicines.

It is possible to utilise the wealth of digital tools available to the chemical industry to enhance methodologies that are already in place

Arcinova applied this innovative approach to the process development of the ketamine metabolite hydroxynorketamine, which had an original synthesis route consisting of seven stages. Developing 1kg of final product would ordinarily have required 40 batches in 20L equipment across the development workflow. By utilising a data-driven approach to process development, Arcinova were able to make significant improvements to the first four stages, increasing the yield from 60% to 95%. This resulted in only eight batches being needed – instead of 24 – and a reduction in timescale to less than 4 weeks for manufacture, thereby doubling the quantity of material in half the time.

Future thinking

In light of the current demand and shift towards personalised medicines, digitally enhanced flow chemistry presents a potent solution to address production limitations. As demonstrated by the success of the Flowinova Project, it is possible to utilise the wealth of digital tools available to the chemical industry to enhance methodologies that are already in place. Chemistry 4.0 continues to gain momentum, and it is anticipated that the emphasis on this data-driven approach to drug manufacture will only grow in the coming years. By improving efficiency in the industry and increasing cost-effectiveness, patients will ultimately be provided with faster access to more tailored medicines.

References

1. Olopade, O.I. et al. (2008) Advances in breast cancer: pathways to personalized medicine, Clin Cancer Res, 14: 7988-7999. doi: 10.1158/1078-0432.CCR-08-1211

No comments yet