Still going wrong! Case histories of process plant disasters and how they could have been avoided

Still going wrong! Case histories of process plant disasters and how they could have been avoided

Trevor Kletz

Oxford: Gulf Professional 2003 | Pp 230 | ?29.95 | ISBN 0750677090

Reviewed by John Cronin

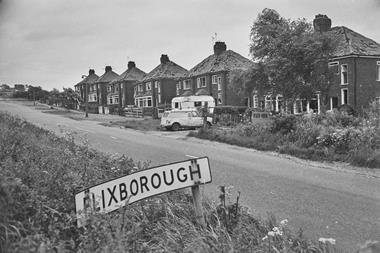

It is a sad fact that our awareness, control and regulation of industrial hazards is often gained through painful experience, following some spectacular disaster. Flixborough, Seveso, Bhopal and Piper Alpha were all salutary process industry examples - in each case the escalation pathway and accident risk were not fully recognised until after the event.

Despite best intentions, the potential for catastrophic accidents, and the cost justification for additional mitigation, are often frustratingly difficult to demonstrate. Our perception of risk is strongly influenced by direct or vicarious experience - this is why documented details of real case histories are invaluable.

Trevor Kletz has dedicated his career to raising awareness in the field of industrial process safety. His earlier publication What went wrong? provided a rich collection of anecdotal experience, gleaned through his erstwhile stewardship of ICI’s internal safety newsletter, and supplemented by external contributions. Still going wrong! builds on the success of this theme, by reporting new and varied case histories and considering the underlying management system failures, in addition to the immediate causes of accidents.

The book kicks off with an explanatory overview, followed by a short but useful glossary comparing UK and US management and technical nomenclature, as used within process accident histories.

In general, the case histories are classified by procedure type (eg methods, maintenance, change), error type (eg communications, knowledge) or consequence type (eg leaks, explosions). Specific chapters detail accidents resulting from combinations of design and operational faults, accidents in other industries and oversights in accident investigation.

This book is an interesting and useful reference on a subject that remains very relevant to today’s chemical and process industries. It will be welcomed by professionals, academics and regulators concerned with continued safe operation in high hazard environments.

No comments yet