In the early 1900s, a Thuringian family firm developed standard ground glass joints, now commonly referred to as Quickfit

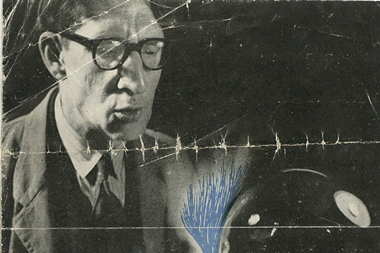

There aren’t many films based on chemistry. My favourite is the Ealing comedy ‘The Man in the White Suit’, a dystopian story of an obsessive chemist who invents an indestructible fibre. Written before microplastics and industrial off-shoring, it eerily documents a bygone age. The stark black and white photography captures misty urban-industrial landscapes, deep chiaroscuro shows factory interiors, and detailed closeups capture polymer processing and weaving.

In a key moment that chemists should watch in slow motion, a clutch of managers enters the technical laboratory of the factory. A slow panning shot reveals a world of volumetric glassware, and a chemist pipetting by mouth while others tinker with flasks and clipboards. A brooding apparatus featuring a glass spiral, glass tubes and flasks sits in a corner, accompanied by a peculiar bubbling musical leitmotif, at once mocking and sinister, and the obligatory dry ice ‘smoke’.

Yet chemists will note that despite the familiarity of the glassware, something is slightly off. Even in the 1950s there is no sign of the standard ground glass joints – known in the UK as Quickfit – that are ubiquitous in our labs. Today we take these joints completely for granted, but their arrival took decades.

Glass blows up

The rise of chemistry in the 19th century was made possible by the industrial growth of glass equipment firms, some of which originated in the high Renaissance. Specialist scientific glassblowing emerged in Thuringia, the region around Jena in the southern part of Prussia, where a cadre of highly skilled glassblowers gradually shifted from ornamental work, making chandeliers and wine glasses, to the technical.

The first of these scientific glassblowers may have been Franz Ferdinand Greiner (1808–1855) from the village of Stützerbach. Greiner began making thermometers in the 1830s after meeting the itinerant glassblower Wilhelm Berkes, eventually making 64 different models in addition to lab glassware and even chemical toys. His success resulted in many local firms switching to scientific work. Among the most famous Thuringian glassblowers are Hermann Geissler, the inventor of the eponymous pump and discharge tubes, and Otto Baumbach, who made the delicate glassware that Ernest Rutherford used to prove that radioactivity involved transmutation.

The first of these scientific glassblowers may have been Franz Ferdinand Greiner (1808–1855) from the village of Stützerbach. Greiner began making thermometers in the 1830s after meeting the itinerant glassblower Wilhelm Berkes, eventually making 64 different models in addition to lab glassware and even chemical toys. His success resulted in many local firms switching to scientific work. Among the most famous Thuringian glassblowers are Hermann Geissler, the inventor of the eponymous pump and discharge tubes (Chemistry World, May 2019, p70), and Otto Baumbach, who made the delicate glassware that Ernest Rutherford used to prove that radioactivity involved transmutation.

The rise of the electric lamp industry at the end of the 19th century gave further impetus to the industry and resulted in a sudden demand for skilled glassblowers across Europe. The firm of Greiner & Friedrichs (the relation to the earlier Greiner is uncertain) was established in 1852. James Dewar famously entrusted them with the manufacture of vacuum flasks which, to Dewar’s chagrin, they marketed under the name Thermos. The firm also made Conrad Röntgen’s first x-ray tubes. Among the many glassblowers who worked with or were trained by the firm was Otto Schott, who conducted some of his experiments on glass composition in collaboration with them. This collaboration led to the hard and chemically resistant Jena glass, whose logo was the pride of many a British distributor in the 1920s.

The rise of the electric lamp industry at the end of the 19th century gave further impetus to the industry and resulted in a sudden demand for skilled glassblowers across Europe. The firm of Greiner & Friedrichs (the relation to the earlier Greiner is uncertain) was established in 1852. James Dewar (Chemistry World, August 2008, p75) famously entrusted them with the manufacture of vacuum flasks which, to Dewar’s chagrin, they marketed under the name Thermos. The firm also made Conrad Röntgen’s first x-ray tubes. Among the many glassblowers who worked with or were trained by the firm was Otto Schott (Chemistry World, May 2015, p37), who conducted some of his experiments on glass composition in collaboration with them. This collaboration led to the hard and chemically resistant Jena glass, whose logo was the pride of many a British distributor in the 1920s.

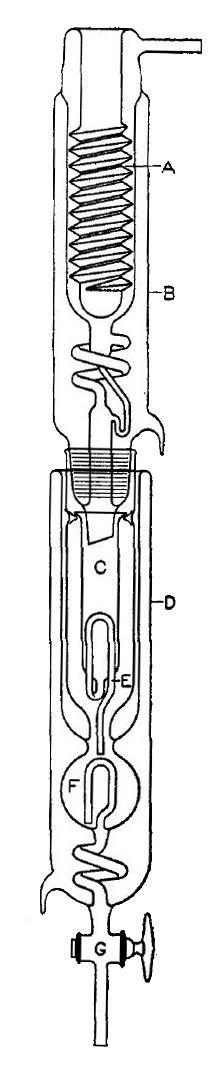

The owner of the firm, Ferdinand Friedrichs, had two sons, Fritz and Josef, both of whom would enter the business. Little is known about Josef but Fritz studied inorganic chemistry in Stuttgart and then researched binary mixtures of water, ammonia and/or hydrazine at the Carnegie Institute at Cornell University in the US. He was already a fine glassblower at this time. He had published several papers on new glassware, including one describing the only device that still bears his name: a condenser with an angular screw-threaded core, which caused the solvent vapour to follow a spiral path upwards.1 Friedrichs would reuse the screwthread design in several other devices including a gas washing device and a modified Kaliapparat. Several of Friedrichs’ inventions also included ground glass joints.

The owner of the firm, Ferdinand Friedrichs, had two sons, Fritz and Josef, both of whom would enter the business. Little is known about Josef but Fritz studied inorganic chemistry in Stuttgart and then researched binary mixtures of water, ammonia and/or hydrazine at the Carnegie Institute at Cornell University in the US. He was already a fine glassblower at this time. He had published several papers on new glassware, including one describing the only device that still bears his name: a condenser with an angular screw-threaded core, which caused the solvent vapour to follow a spiral path upwards.1 Friedrichs would reuse the screwthread design in several other devices including a gas washing device and a modified Kaliapparat (Chemistry World, September 2009, p69). Several of Friedrichs’ inventions also included ground glass joints.

Ground state

The US and British patent literature from this period contains numerous methods to make ground glass stoppers and connections. Machines for making bottle necks and stoppers make up most of these, but there are also a few attempts to connect tubing with a variety of shaped joints, sometimes with gaskets. Glassblowing texts of the period also refer to methods for making ground glass joints and close-fitting stopcocks. It was a fairly laborious process that typically involved making the two halves separately and then carefully grinding them together with silicon carbide to achieve a good fit. The joints and the valves worked well but were not interchangeable; breakages were disastrous as both parts had to be replaced and the joint reground from scratch.

During the first world war, Friedrichs served as an artillery officer, but he returned to the family firm after the armistice. Austria-Hungary’s defeat brought hard times to the industry, which was also struggling with the limitations of ground glass. More progress was made in the US, where Solomon Acree, an agricultural chemist who had studied in Berlin, proposed a set of steel dies that could be used to make interchangeable glass joints on a lathe.2

Acree’s paper was followed a few months later in Angewandte Chemie by a manifesto written by Johannes Dathe, the secretary of a committee set up by the German Chemical Society to standardise glassware.3 Dathe explained that the myriad devices on sale in Germany were both highly confusing for the buyer and very impractical. Every manufacturer had different screw threads and wing-nuts on their clamps. Flasks and condensers were all of different diameters so you couldn’t even use the same cork from one experiment to the next. Hose connections never matched. Such a system made life impossible not just for chemists in the lab but also for wholesalers and distributors who had to stock endless variants. Above all, the lack of standardisation was a massive constraint on profitability, especially if German products were to break in to that huge emerging market, the US.

With his unique experience of laboratory chemistry and industrial manufacture, Friedrichs was a valuable member of the standardisation committee. He wrote five articles in successive issues of Angewandte Chemie laying down standard dimensions for glassware.4 Stopcocks, filters, extractors, separating funnels and condensers were all addressed and a gradual convergence towards standard laboratory equipment across Germany began. Greiner & Friedrichs was now one of the major producers in Stützerbach, and references to its products appear in most of the contemporary guides and textbooks of synthetic techniques, such as Houben–Weyl.

Standard issue

In 1924, another firm in Stützerbach, Wilhelm K Heinz, began producing standard glass joints and a range of glassware equipped with them. Its owner, Werner Heinz, was so proud of the product that the firm’s logo was designed with a crossed cone and socket. In 1927 W K Heinz took out a series of advertisements in Nature illustrating their innovative products. The firm’s catalogue from 1934 looks thoroughly modern, using cross-sectional diagrams showing cones and sockets, rather than the more traditional artistic woodcuts. Greiner & Friedrich began producing standard joints at the same time. By 1929 there was a German DIN (Deutsches Institut für Normung) standard for tapered ground glass joints and their use would gradually spread as production increased and costs dropped.

Both firms continued production up until the second world war. Although apparently undamaged by the fighting, both firms found themselves on the Soviet side of the Iron Curtain. The Heinzs and the Friedrichs fled to the West, their factories taken over. Fritz would work with the Americans to outline how the glass industry could be rebuilt as part of the Marshall Plan. At the same time, he and his brother Josef would set up a new glassworks called, appropriately, Normschliff Glasgeräte Gmbh (the Standard Ground Joint Glass Equipment Company) in the town of Wertheim, which would employ several thousand people and continue production into the 2000s. W K Heinz still exists, making scientific glassware and ground glass joints under family management.

Friedrichs died in 1958, leaving behind a wealth of glassware designs and standards. His 1951 book Das Glas im Chemischen Laboratorium, which he dedicated to his father, is a glorious technical tribute to the contribution that glassblowers have made to modern science.

Were any chemistry film made today, there would not be a cork or a bung in sight. Tapered joints would be everywhere. Yet none of them would bear the mark of Heinz or Friedrichs, but they might well have a stylised blue logo in the shape of a double-walled letter Q: the logo of Quickfit. However, as we’ll see in the next article in this series, it was another, now forgotten, firm that introduced standard ground glass joints to Britain: W G Flaig.

Were any chemistry film made today, there would not be a cork or a bung in sight. Tapered joints would be everywhere. Yet none of them would bear the mark of Heinz or Friedrichs, but they might well have a stylised blue logo in the shape of a double-walled letter Q: the logo of Quickfit, a story we will explore next month.

Acknowledgements

I am hugely indebted to a huge number of people who helped with this article. Among them are David Allan, glassblowers John Cowley, Reece Bramley, Ian Pearson (BSSG), and Alan Gall, archivist for the Institute of Science and Technology, Sheffield. Anna Hillier found company information about Greiner & Friedrichs while Christoph Salzmann and Timoer Frelinck made ultimately fruitless efforts to get information and images from W K Heinz.

References

1 F Friedrichs, Angew. Chem., 1910, 33, 2425

2 S F Acree, J. Ind. Eng. Chem., 1919, 11, 338

3 J Dathe, Angew. Chem., 1919, 32, 207

4 F Friedrichs, Angew. Chem., 1920, 33, 56; ibid. 151; ibid. 157; ibid. 163; ibid. 186.

The story of Quickfit, part one: Friedrich's joints

In the first article in a special Classic Kit series on Quickfit, Andrea Sella tracks the origin of standardised ground glass joints to 1900s Prussia

Currently

reading

Currently

reading

Friedrichs’ joints

- 2

- 3

No comments yet