How the supreme glassblower of his day shows the value of technical staff

Our department lost its mechanical workshop recently. A huge facility with all manner of mills and lathes, it was rationalised and combined with the workshops in engineering. While there were plenty of reasons why this had to happen, the decision was met with gloom. Technicians matter, and losing their experience puts at risk innovation and development that can only take place through face-to-face contact. One of the more spectacular examples of this was the glassblower Heinrich Geissler, who devised the first true high vacuum pump and permanent discharge tube.

Heinrich Geissler was born in the small town of Igelshieb in the German region of Thuringia, a forested area renowned for its glass works. His parents ran one such business, which specialised in higher-value technical glassblowing, especially the manufacture of thermometers and barometers. Geissler was one of 12 siblings, and it was natural that he should start working at a very young age with little schooling. By age 14 he is recorded as being a craftsman. He soon left home, and is believed to have apprenticed as a glassblower in several universities before working with one of his brothers in The Hague, Netherlands in the early 1840s.

By 1852, he was back in Germany, having set up a workshop at the University of Bonn. He was by now an outstanding instrument maker, and was one of four Germans to be awarded a silver medal at the Paris Exhibition of 1855. In Bonn he met the professor of mathematics, Julius Plücker, who asked Geissler to build him some accurate ‘compensating thermometers’. Geissler obliged, then developed devices for measuring the vapour pressure of alcohol and dissolved CO2 in liquids. He also developed an all-glass balance that would be essential for Plücker’s magnetic investigations.

Around 1857, Plücker’s assistant, Theodore Meyer, instructed Geissler to build him some gas discharge tubes about 40cm long with platinum electrodes embedded in the ends in order to study the patterns of dark and bright regions in the discharge. Geissler had in fact already been making such tubes for the instrument maker Heinrich Rühmkorff in Paris, and had become aware that the vacuum pumps of the time – basically piston pumps little changed since the 17th century – were not up to the job. Geissler came up with an ingenious solution.

Inspired by Evangelista Torricelli and Vincenzo Viviani, who had ‘created’ a vacuum simply by using mercury in a sealed tube, as well as by the experiments of Robert Boyle and Edme Mariotte, Geissler wondered whether the mercury could not be used as a piston to move gas around.

The pump he developed was simple in principle. Using flexible rubber hose, one could raise or lower the level of a mercury reservoir connected to a glass tube. The tube was equipped with a three-way hollow ground-glass stopcock of Geissler’s own design. By alternately raising and lowering the mercury and turning the stopcock, gas could be drawn out of one manifold and transferred into another, or expelled to the atmosphere. Although extremely slow, with patience one could quite easily pump a bulb to unheard of pressures and refill it with specific gases or vapours. It was a revolutionary design that would open the path to the investigation of high vacuum, and within a decade inspired August Töpler and Hermann Sprengel to design faster pistons.

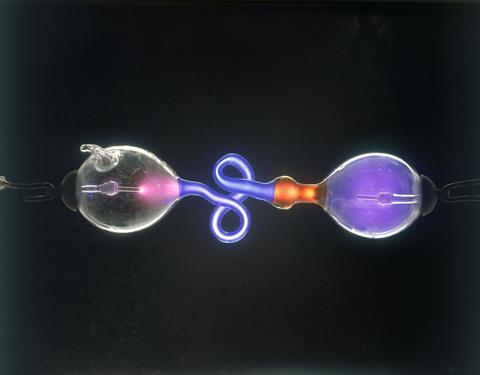

Geissler made several further innovations. He developed a method for embedding platinum wires in glass, either using liquid mercury as a sealant or by matching the coefficient of expansion of the glass to that of the wire, to create gas discharge tubes. Often made in fluorescent uranium glass, or with sections surrounded by a jacket containing fluorescein or other dyes, and powered by Rühmkorff’s induction coil, Geissler’s exquisite designs – full of bubbles, curves and twists – gave off a mesmerising glow when a high voltage was applied. Soon Geissler tubes and their mysterious ‘electric light’ were in demand, both for scientific demonstrations and as spectacular adult toys for middle class gentlemen.

By now Plücker was seriously interested and poor Meyer, possibly miffed by his boss muscling in on ‘his’ area of research, left for Marburg. The relationship between Plücker and his apparatus maker was not always smooth – Plücker complained that Geissler kept mucking about with the shape of the tubes, Geissler that he didn’t get enough credit for his contribution to the work, not least the recognition that different gases gave different colours.

Yet for all the tension between them, Plücker would later support Geissler for the unheard of award of an honorary doctorate from the university in 1868. By then Geissler’s fame had spread, and his students and apprentices would go on to have a huge impact across Europe as the subatomic world was revealed.

Geissler was a supreme instrument maker, and perhaps the best example of why close partnership between technical and academic staff is so critical. Not only do we need in-house workshops, but we must also encourage our technicians with their decades of experience to participate in our play. What might we discover together?

Our department lost its mechanical workshop recently. A huge facility with all manner of mills and lathes, it was rationalised and combined with the workshops in engineering. While there were plenty of reasons why this had to happen, the decision was met with gloom. Technicians matter, and losing their experience puts at risk innovation and development that can only take place through face-to-face contact. One of the more spectacular examples of this was the glassblower Heinrich Geissler, who devised the first true high vacuum pump and permanent discharge tube.

Heinrich Geissler was born in the small town of Igelshieb in the German region of Thuringia, a forested area renowned for its glass works. His parents ran one such business, which specialised in higher-value technical glassblowing, especially the manufacture of thermometers and barometers. Geissler was one of 12 siblings, and it was natural that he should start working at a very young age with little schooling. By age 14 he is recorded as being a craftsman. He soon left home, and is believed to have apprenticed as a glassblower in several universities before working with one of his brothers in The Hague, Netherlands in the early 1840s.

By 1852, he was back in Germany, having set up a workshop at the University of Bonn. He was by now an outstanding instrument maker, and was one of four Germans to be awarded a silver medal at the Paris Exhibition of 1855. In Bonn he met the professor of mathematics, Julius Plücker, who asked Geissler to build him some accurate ‘compensating thermometers’. Geissler obliged, then developed devices for measuring the vapour pressure of alcohol and dissolved CO2 in liquids. He also developed an all-glass balance that would be essential for Plücker’s magnetic investigations.

Around 1857, Plücker’s assistant, Theodore Meyer, instructed Geissler to build him some gas discharge tubes about 40cm long with platinum electrodes embedded in the ends in order to study the patterns of dark and bright regions in the discharge. Geissler had in fact already been making such tubes for the instrument maker Heinrich Rühmkorff in Paris, and had become aware that the vacuum pumps of the time – basically piston pumps little changed since the 17th century – were not up to the job. Geissler came up with an ingenious solution.

Inspired by Evangelista Torricelli and Vincenzo Viviani (Chemistry World, September 2016, p70), who had ‘created’ a vacuum simply by using mercury in a sealed tube, as well as by the experiments of Robert Boyle and Edme Mariotte, Geissler wondered whether the mercury could not be used as a piston to move gas around.

The pump he developed was simple in principle. Using flexible rubber hose, one could raise or lower the level of a mercury reservoir connected to a glass tube. The tube was equipped with a three-way hollow ground-glass stopcock of Geissler’s own design. By alternately raising and lowering the mercury and turning the stopcock, gas could be drawn out of one manifold and transferred into another, or expelled to the atmosphere. Although extremely slow, with patience one could quite easily pump a bulb to unheard of pressures and refill it with specific gases or vapours. It was a revolutionary design that would open the path to the investigation of high vacuum, and within a decade inspired August Töpler (Chemistry World, January 2011, p68) and Hermann Sprengel (Chemistry World, February 2008, p67) to design faster pistons.

Geissler made several further innovations. He developed a method for embedding platinum wires in glass, either using liquid mercury as a sealant or by matching the coefficient of expansion of the glass to that of the wire, to create gas discharge tubes. Often made in fluorescent uranium glass, or with sections surrounded by a jacket containing fluorescein or other dyes, and powered by Rühmkorff’s induction coil, Geissler’s exquisite designs – full of bubbles, curves and twists – gave off a mesmerising glow when a high voltage was applied. Soon Geissler tubes and their mysterious ‘electric light’ were in demand, both for scientific demonstrations and as spectacular adult toys.

By now Plücker was seriously interested and poor Meyer, possibly miffed by his boss muscling in on ‘his’ area of research, left for Marburg. The relationship between the Plücker and his apparatus maker was not always smooth – Plücker complained that Geissler kept mucking about with the shape of the tubes, Geissler that he didn’t get enough credit for his contribution to the work, not least the recognition that different gases gave different colours.

Yet for all the tension between them, Plücker would later support Geissler for the unheard of award of an honorary doctorate from the university in 1868. By then Geissler’s fame had spread, and his students and apprentices would go on to have a huge impact across Europe as the subatomic world was revealed.

Geissler was a supreme instrument maker, and perhaps a critical example of why close partnership between technical and academic staff is so critical. Not only do we need in house workshops, but we must also encourage our technicians with their decades of experience, to participate in our play. What might we discover together?

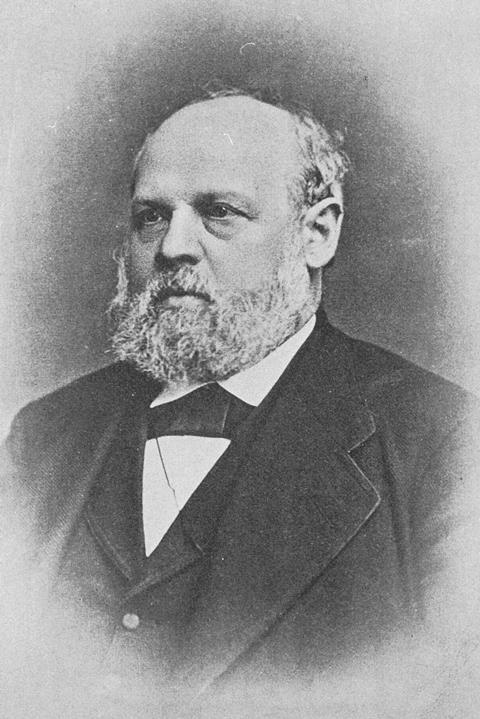

:: FOR PORTRAIT CAPTION::

Heinrich Geissler

German instrument maker (1814–1879). Inventor of the Geissler tube and pump

No comments yet