Precise weighing and sample preparation are critical throughout the lifecycle of battery design, manufacture and material recovery. The experts at Sartorius share their experience of supporting chemists in the analysis and manufacture of safe, high quality batteries for use in a range of applications.

With car manufacturers increasingly developing electric vehicles and bans on new petrol and diesel vehicles set to go into effect in coming years, the need for more effective and efficient batteries has never been more important. The desire to reduce reliance on fossil fuels is speeding up research into new battery materials and battery technology.

R&D in the battery sector has ramped up significantly, and those research efforts are underpinned by analytical chemistry. And underpinning those analytical efforts is the need for accurate weighing, and interference-free sample preparation.

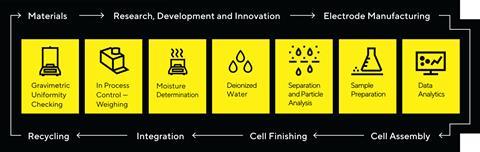

To make a rechargeable battery, there is a clear workflow, and a simplified version is shown below. At the start are raw materials, sourced from mining, extraction or recycling scrap or end-of-life batteries, which may well need refining. Next, cathodes and anodes are produced, with slurries prepared from the materials being coated onto a foil, usually made from aluminium or copper. These have to be dried, calendered and slitted.

The cells are then assembled into individual batteries, with the electrodes being notched before they are stacked, and packed within a cell. Cell finishing follows, which involves filling the cell with electrolyte, ahead of the individual cells being packed into the final module, ready for integration into the vehicle or other device.

After a number of years, the batteries will reach the end of their useful life within that device. There are several options. It may be possible to reuse the cells in another application that requires less power, such as a storage system for wind energy, for example. The batteries could also be crushed, and the metals within them recovered and reused, returning the raw materials back to the start of the workflow, creating a circular process.

Raw materials

At many points in this workflow, precise weighing and sample preparation is critical. At the outset, it is vital that the raw materials are of the necessary purity. ‘After extraction or recycling, accurate, high resolution balances – if not microbalances and ultramicrobalances – are essential when making, for example, density checks,’ says Myriam Gueye, Segment Marketing manager at Sartorius. ‘Similarly, when performing Karl Fischer tests to determine residual water traces or running thermogravimetric analyses, for example, high precision weighing is important if the results are to be sufficiently accurate.’

If water is used to prepare the samples, it’s important that this is exceptionally pure, to avoid introducing impurities. ‘If ghost peaks are introduced, then the accuracy of the tests will clearly be affected,’ she says. ‘High resolution analytics are only possible with high quality sample preparation tools.’

we design our balances to ensure that they can be upgraded as requirements change and technologies move on […] extending the lifetime of the balance rather than having to buy a new one

Myriam Gueye

Effective filtration is also important in ensuring accuracy. Syringe filtration devices, for example, are used to prevent blockage of your HPLC columns. ‘And, of course, in chemical characterisation, if you are wanting to measure the residue of ignition, for example, ash-free filter papers are required,’ she says. These types of sample preparation tools, or pre-analytics, play an important role in the quality of your analytical results.

It is also vital to make specific surface area determination . ‘This is really crucial for the raw material, as it is the surface that will be in contact with the electrolyte,’ she says. ‘The surface is never going to be fully rounded, and imperfections on the surface increase the total surface area. Precision weighing is once again crucial when making these measurements, and balances that can weigh large samples down to microgram levels, not just small ones, are key.’

Of course, there are many other considerations. When weighing raw materials with such high precision, a balance must be easy to clean to ensure no residual material remains to contaminate future weighings. ‘We even design our balances to ensure that they can be upgraded as requirements change and technologies move on,’ Gueye says. ‘Sartorius Cubis balances are fully customisable; perhaps users might want to add or change a draft shield, for example, or upgrade data collection features, extending the lifetime of the balance rather than having to buy a new one.’

With moisture critical, procedures are commonly carried out in a very dry environment such as a glove box, but this is likely to lead to problems with static electricity, potentially resulting in both inaccurate weighings and contamination with the balance that can affect subsequent weighings. ‘A deioniser within the balance can help remove the static effect,’ she says. Other devices, such as antispilling weighing pan and different shaped sample holders, are also useful tools for improving accuracy.

Electrode production development

Clearly, very accurate weighing is also essential in the development of electrodes. To make the slurries for coating, all the active materials, thickeners, binders and additives have to be mixed in very precise mass ratios. ‘In these dosing steps, weigh cells that are integrated into the production line are a valuable tool for speeding up the procedure without losing accuracy,’ Gueye says.

Water is another key component at this stage. Deionised water is used as a raw material, and clearly it is important that this is sufficiently pure that it does not introduce ionic contamination into the mix.

The coating procedure itself is carried out via dispensing heads that accurately dose the slurry, onto the foils to create the electrodes, and integrated weigh cells are used to check the heads are continuously delivering the best precision.

Moisture determination comes into play again in the drying steps, as an intermediary control, but here the moisture is not just water: it is the volatile components, too – anything that can evaporate from the sample.

Cell assembly and finishing

Filling the cell with electrolyte is another step where weight and accuracy are critical. The electrolyte is introduced via a dispensing head, and Gueye says the simplest way of ensuring the correct volume has been delivered is again by weight. ‘For very small batteries, we even have a robotic dispensing head to deliver the electrolyte,’ she says.

Weight, albeit with less need for microgram precision, is a simple way of checking that a battery has been accurately assembled. ‘This is, essentially, check weighing,’ she says. ‘It’s a non-destructive test, and compares whether the weight of the completed battery falls within the required tolerances when compared to a control battery.’ Moisture determination, again, plays a role here, with the purity of the plastics, glue and gap fillers used in the assembly all being checked to minimise further quality issues.

Weighing comes in once more when the individual batteries are packed into the final module, where they are carefully arranged at a constant distance from each other to ensure sufficient cooling to limit overheating, before the terminals are connected with the busbars. Glue and gap filler dispensing heads can again be controlled via a balance or an integrated weigh cell, and of course correct assembly of the entire unit checked by weight.

Recycling and data analytics

There are two forms of material that can be recycled: batteries that have reached the end of their life, but also the scrap offcuts from production. Even for a very efficient manufacturing process, sometimes up to 15% of the material is lost to production scrap. By recovering valuable raw materials, not only will costs be saved, but it will also certainly help companies meet future regulatory requirements for recycling as and when they are implemented.

the more precise you are with your analytics, the more likely you are to avoid safety issues

Myriam Gueye

This scrap is much easier to deal with than exhausted batteries, because it is likely to be far more homogeneous. In contrast, an end-of-life battery will have degraded and the composition of the materials within them will be highly variable. But either way, as they move back into the raw material stream, all the same tests and checks are required to ensure the material that is returned into the production cycle is sufficiently pure.

Data are critical in ensuring accurate production, and also safety, particularly with the risks of thermal runaways from malfunctioning or damaged batteries. ‘The more precise you are with your analytics, the more likely you are to avoid safety issues,’ she says.

Being able to collect data from the balances automatically is a significant advantage when it comes to collating and analysing data effectively. ‘We have applications embedded within our balances that enable data to be collected directly,’ she says.

A tremendous amount of data are collected during battery R&D – petabyte levels. ‘At every stage of the production process, data will be collected. There are so many things that might go wrong, and they need to understand what happened. Our analytics software can, for example, help highlight trends in data, both at the design of experiments stage in R&D, and multivariate analytics later on in production.’

No comments yet