New 'dip and dry' process adds waterproof coatings to a range of materials

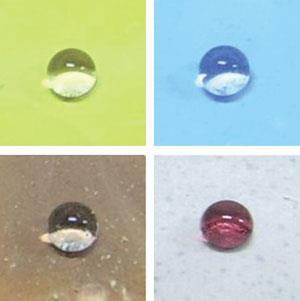

Materials scientists in China have developed a simple process to add an extremely waterproof coating to a variety of materials. The super-hydrophobic coatings can be made in a range of different colours and applied by an easy ’dip and dry’ process.

The research team from Hunan University in Changsha, hope that their new, colourful technology will be useful for making stain-proof clothing, self-cleaning road signs or snow-resistant glass.

Super-hydrophobic coatings are considered the panacea of waterproofing technology. Their water-repelling, self-cleaning capacity is often called the ’Lotus effect’, after the leaves of the lotus plant. The plant grows in muddy lakes and rivers, but its leaves are kept spotlessly clean by tiny wax nanocrystals, which make the leaf surface so rough that water is unable to absorb onto it. Water droplets simply roll off, taking any mud or dirt with them.

Although there are already many synthetic super-hydrophobic materials available, most are very complicated and expensive to produce. The new application process developed by the team is much cheaper and simpler. ’Our coatings can be added by a "dipping and drying" procedure at room temperature,’ says Hua Wang, a lead author on the project, adding that it only takes around 20 minutes for the coating to dry.

The coating is made from a bisphenol A type polycarbonate dissolved in dichloromethane. Materials are dipped into this polymer solution, and then into a non-solvent solution, which causes the polymer to precipitate, forming a super-hydrophobic layer on the material surface.

’Almost all common material substrates can be given our super-hydrophobic coating, including metals, glass, plastic, cement, paper and fabric,’ says Wang. By adding small amounts of oil-based paints or dyes, the team can also make the coating in a range of different colours. They suggest that unusual shapes, such as twisted or tube-shaped objects, which are normally tricky to coat, could be waterproofed via this process.

Avi Marmur, who has worked on similar technology at the Israel Institute of Technology in Haifa, Israel, says the technology is interesting, but that more work needs to be done for outdoor uses. ’The long term problem of all coatings is that they do not withstand the test of exposure to environmental ageing, such as sun and wind,’ he says.

Wang, however, is confident about the potential of the coating. His team is in the process of patenting the new coating and believes that commercial applications could be seen within two years.

Lewis Brindley

No comments yet