Genetically engineered bacteria have been created that can convert polyethylene terephthalate (PET), the polymer plastic bottles are made from, into paracetamol.

The researchers, from the University of Edinburgh and AstraZeneca, both in the UK, said their work demonstrates an integrated chemical and biological approach for sustainable plastic remediation and upcycling.

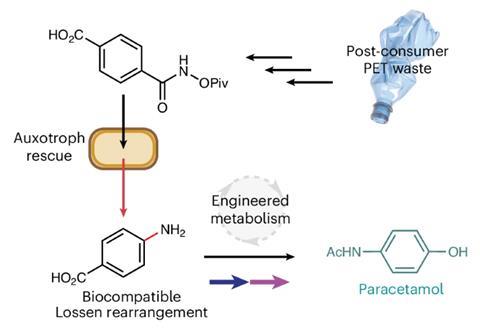

The work started with the discovery that a synthetic reaction, called a Lossen rearrangement, can take place in living cells in mild, non-toxic conditions, using phosphate as a catalyst. Lossen rearrangement is a non-enzymatic reaction that typically converts hydroxamate esters into isocyanates and then amines.

With this knowledge, the researchers designed a biocompatible Lossen rearrangement, which started with an acyl hydroxamate substrate, to generate para-aminobenzoic acid (PABA), a nutrient essential for Escherichia coli growth.

When a strain of E. coli that was deficient in PABA was cultured with various O-acyl substituted hydroxamate esters, without additional catalysts, the researchers found that the bacterium continued to grow, indicating that Lossen rearrangement had occurred within the culture. They later found that the reaction had been catalysed by phosphate in the growth medium.

The researchers then looked at synthesising acyl hydroxamate esters from PET, specifically the PET monomer terephthalic acid, and found that the PABA-deficient E. coli grew just as well with the plastic-derived esters as in the presence of PABA. They then found that by introducing two genes – one from a fungus and one from another bacterium – into the E. coli, PABA could be further converted into paracetamol with a maximum yield of 92%.

The one-pot process was carried out at room temperature and created virtually no carbon emissions, unlike traditional paracetamol production.

The researchers said the findings may be the first instance of paracetamol being produced from E. coli using a waste product and that other types of bacteria or plastic might be used to generate useful products.

References

N W Johnson et al, Nat. Chem., 2025, DOI: 10.1038/s41557-025-01845-5

No comments yet