New strain sensor from Japan uses carbon nanotube network that separates and folds back together in the same way each time.

New strain sensor from Japan uses carbon nanotube network that separates and folds back together in the same way each time.

A sensor that can measure the movements of a human body has several requirements: it must report the movement quickly and consistently; hug curves; and survive considerable and repeated stretching. A material that ticks all the boxes is hard to come by, but researchers in Japan say their new carbon nanotube strain sensor can do it all.

The sensor measures strain through electrical resistance, which increases as the sensor is stretched. Unlike similar sensors, the sensor made by Kenji Hata and his colleagues at the National Institute of Advanced Industrial Science and Technology in Tsukuba can withstand and measure huge strains repeatedly.

Hata has shown that the sensor can be extended to 280 per cent beyond its normal size, survive 10,000 repeated stretches to 2.5 times its length, and report stretching after just a 14 millisecond delay - the shortest known for a material that can measure such large strains.

’The performance and strains reported are exceptional,’ says Gordon Wallace director of the Intelligent Polymer Research Institute at the University of Wollongong in Australia, adding that the sensors ’far exceed anything previously reported in the scientific literature.’ John Rogers who works on flexible circuits and sensors at the University of Illinois at Urbana-Champagne in the US is also ’very impressed’ and describes as the design as ’clever’.

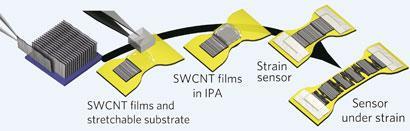

Hata and his colleagues grew thin films of single-walled carbon nanotubes and set the films onto a piece of silicon rubber with the length of the tubes running broadside to the direction of the strain. A drop of isopropyl alcohol pushed out the air between the film and the substrate, creating strong adhesion.

The first pull on the dense network of carbon nanotubes generates cracks between them, turning the network into a series of thick islands and filamentous bridges. The bridges create bottlenecks in electron traffic and this showed up as resistance in the sensor’s electrical conductivity.

When strain is released, the bridges and islands fold back into a network of parallel carbon nanotubes like an accordion, but next time the sensor is stretched, they reappeare in the same configuration. The material does not repeatedly break in new places and according to Hata this is the key to the sensor’s durability. Hata has even shown that the sensor has outlasted the silicon rubber it’s attached to.

In addition to testing the properties of the sensor, Hata and his colleagues have also attached it to bandages, stockings and gloves to test how well it detected the motion of a human body. ’Any large motion can be detected, and it can be used for millions of times,’ explains Hata.

Affixed to the chest as a respiration monitor, the team suggest it might help prevent sudden infant death syndrome (SIDS) but Hata’s favourite application is the "data glove", which senses the movement of each finger. The group’s glove sensed the motions of typing, but they say a version could be used to guide robots which perform surgery. Hata also has more fun applications in mind, such as game controllers and virtual reality systems.

Kate McAlpine

References

Nat. Nanotechnol., 2011, doi: 10.1038/NNANO.2011.36

No comments yet