A smart fabric could help keep you cool by modifying heat transfer depending on how hot or cold you are – or rather how sweaty you are. The material could lead to clothing that can keep you warm in cold conditions or help cool you when it’s hot.

Infrared radiation is responsible for around 40% of our bodies’ heat loss. While smart textiles have been made before that either enhance or prevent infrared absorption to retain or lose heat respectively, no fabric had been designed that can do both.

‘Our textile is the first that can dynamically gate infrared radiation,’ says YuHuang Wang, who led the study at the University of Maryland, US. ‘This is desirable as it turns your clothes into an automatic thermoregulation system that is dynamically responsive to one’s personal thermal discomfort.’

The initial inspiration came when Wang was thinking about how responsive clothing could be a solution to save energy in buildings. ‘It was an “aha” moment,’ he says. ‘I was looking at the blinds in my office window and it occurred to me that we need a switch for our clothes.’

Joining forces with Maryland physicist Min Ouyang, the team has now designed a ‘metatextile’. The textile is akin to a window blind that can block or permit infrared radiation to pass through it – in this case in response to moisture such as sweat and thus, indirectly, to body temperature.

Spinning a yarn

The textile is knitted from a yarn of triacetate cellulose, which is already used in clothing. The material can respond to humidity because the triacetate in each fibre absorbs water while the cellulose component repels it. This opposition causes fibres in each thread to tighten and twist together the wetter they get, creating larger pores between overlapping threads for heat to escape through. Conversely, when dry the fibres relax and spread out, which shrinks the pores and reduces heat loss.

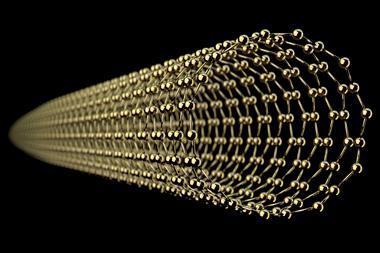

Knowing this property of triacetate cellulose, the team wondered if they could use it to modulate IR heat transfer by coating the yarn with carbon nanotubes (CNTs), which possess excellent thermal conductivity. CNTs can modulate infrared radiation emission because electromagnetic interactions at the infrared wavelength-range alter depending on the distance between the CNTs – known as resonant electromagnetic coupling.

The closer the CNTs get, the greater the coupling effect and the more infrared radiation is dissipated. However, the further apart they are the less infrared radiation escapes. This means that as the yarn twists tighter in response to moisture the nanotubes get bunched up and dissipate heat more efficiently, whereas the reverse happens as the fibres relax, helping to retain heat.

Smart switch

‘No one before had found a way to switch both the porosity and infrared transparency of a textile so as to provide increased comfort in response to environmental conditions,’ comments Ray Baughman, a nanotechnology expert developing CNT yarns at the University of Texas, US. ‘There are many opportunities for improving and generalising this remarkable technology for clothing textiles.’

To demonstrate its scalability, the team knitted a 0.5m2 piece of fabric using triacetate cellulose threads and then coated the cloth with CNTs. Experiments that controlled humidity in an environmental chamber revealed the fabric would be able to both cool and insulate a person at the range of temperatures experienced in everyday life.

What’s more, the textile responds in less than a minute, so clothes made with this yarn could be helping regulate your body temperature before you even feel too hot or cold. However, Wang acknowledges that rain or extreme environmental humidity could prevent the textile from working properly.

The researchers have applied for a US patent and now get into high performance clothing. ‘We are hoping to make the first applications in sports apparel since thermal management is key to performance,’ says Wang. ‘This technology may also find use in infant care and others who need constant attention to thermal comfort.’

References

X A Zhang et al, Science, 2019, 363, 619 (DOI: 10.1126/science.aau1217)

No comments yet