Researchers in China have created a dual-phase ceramic that deforms rather than cracks when compressed. The team believes the technique, in which silicon nitride absorbs stress through bond switching during gradual phase change, could potentially be applied in other hard ceramics made from covalent bonds.

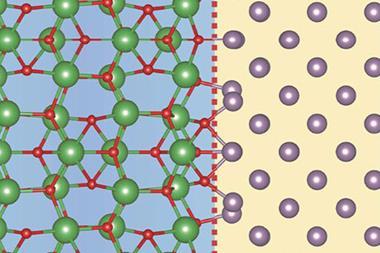

Covalent ceramics like silicon nitride are among the strongest, hardest materials in engineering because of the rigid chemical bonds network holding the structure in place. However, this also tends to make them brittle as they cannot easily absorb energy by deformation. Ceramics such as zirconium dioxide, which is used in dentistry, can show slight plasticity through microstructural transformations. However, zirconium dioxide is regarded as an ionic compound – its atomic planes can slip past one another when pressure is applied. This isn’t possible in covalent ceramics.

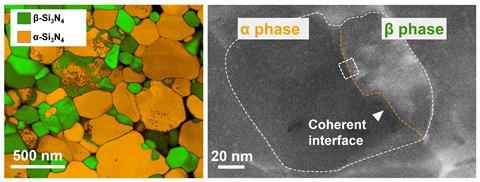

But Kexin Chen and colleagues at Tsinghua University in Beijing found a way to double the fracture strength of silicon nitride nanopillars. Silicon nitride (Si3N4) is used in everything from cutting tools to microshutters aboard the James Webb Space Telescope. It has two polymorphs, α and β. The conventional sintering process forms almost pure β-Si3N4 crystal. However, the researchers devised a lower-temperature sintering protocol that produces a ceramic in which each grain contains α and β regions.

When compressed, the grains undergo a phase transition towards α-Si3N4, releasing strain energy stored in the bonds. This occurs through a process of bond breaking and immediate, and permanent, rebonding at the interface that the researchers term bond switching.

The researchers believe deformable silicon nitride could be useful for applications from bulletproof armour to engine components and artificial hip joints. Moreover, they note that other ceramics, such as the ultrahard silicon carbide, have multiple polymorphs and could therefore potentially be toughened by the same mechanism.

‘Scientifically, it’s very interesting: I don’t think I’ve seen anything like this before in these kinds of materials,’ says materials scientist Nitin Padture of Brown University in Rhode Island in the US. He notes, however, that materials are weaker when stretched than when compressed because, when cracks initiate, they are pulled open and propagate throughout the material. ‘It’s really the toughness in tension that’s the Achilles’ heel in ceramics,’ he says. He believes the dual-phase ceramic should also be tested under tension – rather than just compression – by introducing a crack. ‘My money is that fracture will occur without evidence of this kind of boundary motion occurring in front of the crack tip.’

Padture does, however, think bond switching could conceivably increase tension resistance in other ceramics where the atoms can rearrange at lower strains – but not ultrahard ones like silicon carbide, in which the bonds are even more rigid than in silicon nitride.

References

J Zhang et al, Science, 2022, 378, 371 (DOI: 10.1126/science.abq7490)

No comments yet