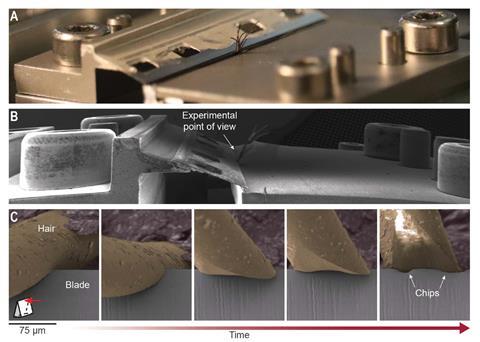

Have you ever wondered how something as tough as a razor blade gets blunted by trimming something as soft as human hair? Researchers at the Massachusetts Institute of Technology (MIT), US, have now used scanning electron microscopy to watch how hair wears down these sharpened shards of stainless steel, a material that is 50 times harder than hair.

The key is that the blade’s edge is covered in tiny imperfections to begin with. Even very sharp, fresh blades have numerous microscale notches running along their surface. The MIT team’s simulated shaving experiments showed that it’s the location of those imperfections relative to hair follicles that contributes to the wear on the blade.

Microcracks were more likely to seed when a notch came into contact with the outer edge of a hair strand. These cracks initially cut straight into the blade, but can change direction and form wider chips in the blade’s edge. Changes in the cutting angle as hairs bend and the distribution of carbides within the blade material also influence the chipping process.

The researchers suggest that longer lasting blades could be designed by using more homogenous materials or perhaps nanostructured alloys to create a more uniform cutting edge.

References

G Roscioli, S M Taheri-Mousavi and C C Tasan, Science, 2020, DOI: 10.1126/science.aba9490

No comments yet