New system allows polymers to 'self-heal' repeatedly

US researchers have taken a leaf out of nature’s book to develop a polymer-based system that can heal itself when it becomes damaged. The material relies on an underlying network of vessels - similar to blood capillaries - that carry a healing agent to areas on the material’s surface that become damaged. Unlike previous self-healing systems that relied on capsules of agent buried in the polymer and which became depleted after one use, the new system can respond to damage at the same point many times over.

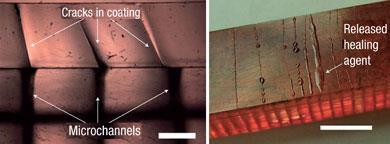

Nancy Sottos’s team at the University of Illinois used a technique called direct-write to create an epoxy-resin base infused with a network of interconnected horizontal and vertical channels 200

m in diameter. These channels were filled with low-viscosity, monomeric dicyclopentadiene - the healing agent. A solid epoxy resin layer was deposited on top of the vascularised substrate. Grubbs’ catalyst, benzylidene-bis(tricyclohexylphosphine)dichlororuthenium, was incorporated into this outer coating.

’After damage occurs at the coating, healing agent wicks from the microchannels into the crack(s) through capillary action,’ the researchers report in the journal Nature Materials. ’Once in the crack plane the healing agent interacts with the catalyst particles in the coating to initiate polymerisation, rebonding the crack faces autonomically. After a sufficient time period the cracks are healed and the structural integrity of the coating restored. As cracks reopen under subsequent loading the healing cycle is repeated.’

The ability of the system to heal itself repeatedly is significant. Previous work with self-healing systems involved the use of capsules of healing agent embedded within the polymer substrate. These could only be used once before being spent.

The Illinois team likens the system to that found in nature. ’Healing in biological systems is accomplished by a pervasive vascular network that supplies the necessary biochemical components,’ they noted. ’A cut in the skin triggers blood flow from the capillary network in the dermal layer to the wound site rapidly forming a clot. Owing to the vascular nature of this supply system minor damage to the same area can be healed repeatedly.’

Ian Bond, of the aerospace composites research group at the University of Bristol, UK, is impressed. ’In the world of high-performance materials such as aerospace, where there are many safety-critical aspects, the idea of self-healing materials is very attractive if you can make it work,’ Bond told Chemistry World. ’This study moves the subject of self-healing forward into a situation where you can have repeated healing, something that has not been demonstrated up to this point.’

The concept of ’vascularising’ a polymer substrate is also intriguing, he said. ’This could lead to many more applications, such as thermal management. The idea of a vascular network in these materials is very interesting in its own right.’

Simon Hadlington

Enjoy this story? Spread the word using the ’tools menu’ on the left.

References

K S Toohey et al, Nat. Mater., 2007, DOI: 10.1038/nmat1934

No comments yet