Vaccines could be made cheaper and more effective using nanoparticle manufacturing techniques

Laura Howes/San Diego, US

Applying nanoparticle fabrication techniques to vaccine production could dramatically cut their cost per dose. Joseph DeSimone and his spin out Liquidia, presented their nano-production process for vaccines at the American Chemical Society annual meeting in San Diego, US, and hope that their work will improve immunisation rates in the developing world.

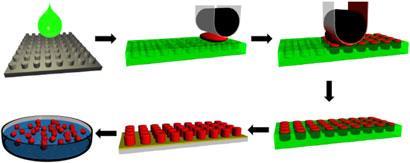

DeSimone has done a lot of work on the mass production of nanoparticles using nanolithography - materials are moulded and then transferred to films in a streamlined, reel to reel, process. ’We say we’re harnessing the power of the precision and uniformity of the microelectronics industry for making vaccines and medicines,’ he explains. And because this is a dry moulding technology, with no concerns about partitioning, DeSimone adds, ’you can access compositions you couldn’t access before’.

Altering the material properties of nanoparticles - shape, charge, flexibility - can change where they end up in the body. This property holds great potential for drug delivery, but also for vaccinations. Vaccine makers have started moving away from using live viruses or bacteria for immunisation due to safety concerns, but just using viral coat proteins or polysaccharides from the surface of bacteria is not as effective. ’We know damn well your innate immune system processes these small molecules much differently to larger objects [like bacteria],’ says DeSimone.

Adding these viral coat proteins or sugars to nanoparticles can improve the efficacy of the treatment and Liquidia now have one such vaccine in Phase I clinical trials and several others in development. But DeSimone is suggesting going one better, making the nanoparticle completely out of bacterial polysaccharides.

The vaccine DeSimone wants to make will be targeted against Streptococcus pneumonia, a bacterium that causes pneumonia. Doctors are currently battling antibiotic resistant strains of the bacterium. And of course, once the technology has been shown to work for one vaccine, the technique could be targeted at other diseases. ’If this turns out to be plug and play the way we think it is,’ says DeSimone. ’It’d be really powerful to have all sorts of vaccines.’

’I think Joe’s work is great,’ says Bob Langer from the Massachusetts Institute of Technology, US. ’I think materials science can broadly affect medicine. Designing materials that can provide targeted or controlled release of vaccines is one important area.’

No comments yet