Sustainable technologies combined to make grapes go further

Italian scientists have devised an innovative and economically feasible biorefinery that can squeeze more chemicals out of the mountains of grape waste produced during wine production.

Last year around 28 billion litres of wine were produced globally – enough to fill over eleven thousand Olympic sized swimming pools. But after pressing the last of the juice from the grape, a whole lot of skins and seeds are left – around 5 million tons of the stuff.

Traditionally this waste, known as pomace, is redistilled to produce spirits such as grappa. But changes in EU policy have reduced the subsidies given to distillers in an attempt to get more from this resource. Though useful chemicals such as polyphenols (natural antioxidants used in cosmetics and preservatives) or methane-rich biogas can be extracted from red grape pomace, you’d be hard pressed to turn a profit from existing single-product valorisation processes.

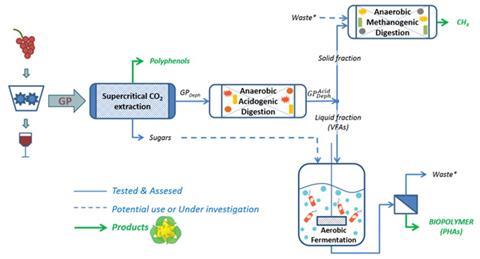

Raise a glass then to Lorenzo Bertin and colleagues at the University of Bologna, who have developed a multi-purpose biorefinery which not only produces polyphenols, but fatty acids, biopolymers, and biomethane too. Using supercritical carbon dioxide, the team extracted the useful polyphenols and sugars, before using anaerobic digestion to produce other useful compounds such as fatty acids. The leftover solid waste underwent further microbial treatment to produce methane, whilst any remaining liquid waste was aerobically fermented to produce environmentally friendly polymeric materials. Bertin’s biorefinery is striking for the sheer range of products it is able to extract from a single integrated process – making this green approach much more industrially viable.

Evan Beach, a biorefinery specialist at Yale University, US, toasts the sustainable chemistry on display. ‘This is an excellent example of life-cycle thinking applied to green technology. It’s been a major challenge to go beyond isolating a single product of interest. Bertin’s team have designed a process that yields a range of valuable products, which helps improve the process economics while minimising the life-cycle impacts of waste streams.’

Gonzalo Martinez, who worked on the project, tells Chemistry World there’s still a wide range of potential products just waiting to be tapped. ‘We’ve only shown one strategy for this biorefinery. If we change the order of steps we will obtain different materials – for instance if we anaerobically digest the pomace before extracting the polyphenols, we’ll obtain other fatty acids which will be even more interesting.’ For Martinez, the ultimate aim is 100% valorisation.

Biorefinery expert Franck Dumeignil, at the University of Lille, France, describes the integrated process as remarkable. ‘The production of multiple high value added products from industrial wastes like this is highly relevant to address the food versus biofuel competition debate.’

References

This article is free to access unti 01 December 2015

G A Martinez et al, Green Chem., 2015, DOI: 10.1039/c5gc01558h

No comments yet