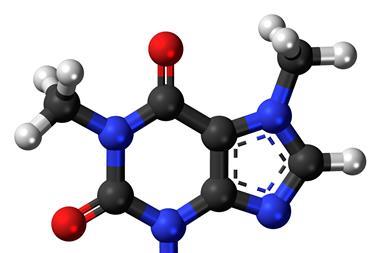

Discovery could help researchers engineer flexibility into designer molecules

Indian chemists have discovered a highly elastic but crystalline material made from caffeine. The crystals maintain their elasticity down to -100°C, and could provide new design principles for making flexible electronic or micromechanical materials that take advantage of the highly ordered nature of crystals to improve energy and charge transfer properties.

Malla Reddy and Soumyajit Ghosh at the Indian Institute of Science Education and Research in Kolkata were attempting to co-crystallise caffeine and another flat molecule, 4-chloro-3-nitrobenzoic acid (CNB), into crystals in which the molecules were arranged in flat, sheet-like layers. When they dissolved the two compounds in methanol and allowed the solvent to slowly evaporate, they got some of these crystals, but also some long needle-like crystals.

Investigating the structure of these needles, it was immediately obvious that they were unusually elastic. ‘Normally, crystalline materials are very brittle and snap when you bend them more than a few degrees,’ Reddy says. Alternatively, the molecules can slip over each other and remain in their new positions when the force is removed, leading to permanent, plastic deformation.

This doesn’t happen for Reddy’s elastic co-crystals – they spring back when released. The team did x-ray diffraction experiments to show the molecules return to the same place after bending. The x-ray studies also revealed the unique features of the crystal structure that give it its properties. The caffeine and CNB are arranged in interlocking comb-like sheets, with channels in between, in which molecules of the methanol solvent are trapped.

‘This flexible co-crystal solvate was completely unexpected,’ says Reddy, adding that the trapped methanol seems to be necessary for the elasticity. ‘Like all solvates, it also tends to lose solvent over time,’ he adds. ‘Without the solvent, the host structure becomes less stable and probably develops some defects which lead to breakage.’

But if the molecules aren’t moving over each other, how does the material bend? Reddy proposes that ‘in the bending process the sheets themselves stretch and contract on the outer and inner arcs of the crystal’, with the trapped solvent molecules helping maintain the relatively weak intermolecular interactions that hold the sheets together as the molecules themselves are pulled apart or pushed together.

The list of performance requirements for elastic materials to be used in applications from flexible electronics to artificial muscles is huge, comments Pance Naumov, who researches functional materials at New York University Abu Dhabi in the United Arab Emirates. ‘Understanding the underlying molecular processes by which an external force generates a mechanical response is critically important for target-oriented design,’ he adds. ‘The results bring research on [these] materials to a new level, where one could screen and possibly intentionally tune the mechanical properties, simply by modifying one or more of the chemical components.’

No comments yet