How comprehensive 2D chromatography from Waters helps scientists hit polymer analysis sweet spots and unravel complex chemical structure

The challenge of separating complex polymer blends for use in military applications is what inspired Waters’ market development manager Jennifer Bain to focus her attention on the benefits offered by comprehensive 2D liquid chromatography.

And though her interest in the technology was initially sparked within an academic environment, Bain has led collaborations with Waters’ customers across industries and leveraged multi-dimensional chromatography during R&D processes to help organisations accelerate their product innovation.

Separating three or even four polymers in a blend enables better and faster R&D decision-making

Jennifer Bain

‘The ability to apply a multi-dimensional chromatographic approach is key to gaining a more robust understanding of the chemical composition of polymers.

‘The process enables separation of analytes by two different, sequential retention mechanisms – allowing for analytes to be separated from other compounds that would normally co-elute in a single dimensional separation. Being able to separate polymeric samples by chemical composition and then by molecular weight is what makes comprehensive 2D chromatography beneficial for researchers in the R&D space,’ says Bain.

‘I see the highlights of multi-dimensional chromatography as answering all the questions that cannot be answered with traditional single dimensional chromatographic analysis. I worked in academic labs where I had impossible polymers to analyse that required all sorts of weird and wonderful analytical techniques thrown together to achieve what were considered the most innovative results at the time,’ she adds.

Investigating block copolymers, Bain was keen to know more about the ratio of blocks in complete or novel polymers ‘because the ratio of two different blocks affects assembling’, she says. ‘With comprehensive 2D chromatography, you see the actual polymer chains whereas in traditional size exclusion chromatography (SEC), you only see a blob.’ Bain adds that, while the technique itself is a bit more complex, once grasped, routine use of the Acquity Advanced Polymer Chromatography (APC) system Waters’ designed specifically for material scientists, becomes an experience to enjoy.

The ability to separate three or even four polymers in a blend enables scientists and chemical engineers to make better and faster decisions during the R&D process, Bain says.

‘Multi-dimensional chromatography is often perceived as quite advanced and scary, but it isn’t as inaccessible as many believe it to be – at least not anymore,’ says Bain. ‘Many see it as being only for specialists and academics or experts in that type of technique, but it’s becoming more and more relevant and accessible – especially as organisations seek to gain a competitive advantage by taking their products to market before the competition.

‘We decided to expand the capabilities of our APC System to support materials scientists with deeper insight into today’s complex polymer blends and increasing use of sustainable alternatives such as lignin and polylactic acid (PLA), which require more advanced separation techniques.’

System configuration

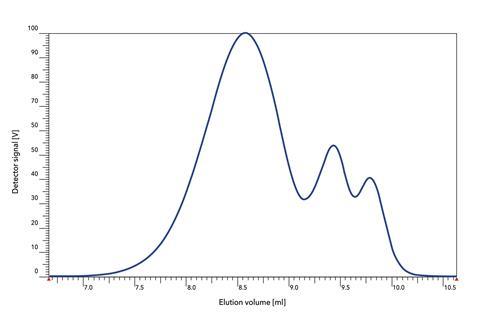

As R&D becomes more complex, the need for multi-dimensional separations is becoming more prevalent, especially for analysis of both co-polymers and architectural polymers. Size exclusion chromatography (SEC) is considered the go-to technique for polymer chemists and material scientists, with both molecular weight and polydispersity influencing the bulk properties of the resulting materials.

A growing demand for advancement in the materials sciences calls for an improvement in both LC technologies and separation methods to overcome challenges experienced with traditional SEC – which often suffers from limited peak resolution, low peak capacity, convoluted peaks, co-elution of species, and difficulty identifying impurities in the sample.

Increasing analyses’ peak capacity with comprehensive 2D chromatography

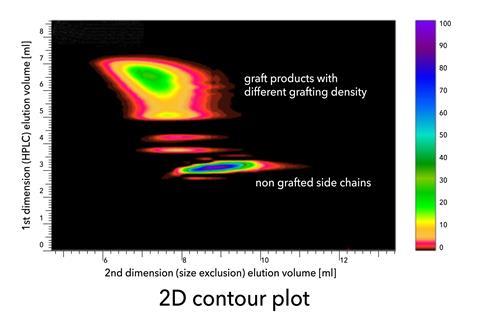

Comprehensive 2D separations offer a new level of insight for 2D analysis of complex polymer samples, offering analysts huge improvements in both separation selectivity and peak capacity. 2D separation combines separation first by chemistry and then by size, significantly enhancing the identification of components in complex polymer samples such as co-polymers and polymer blends. The result is improved separation selectivity and peak capacity.

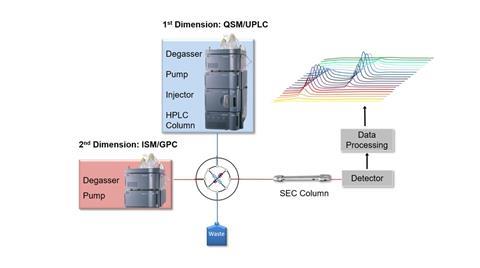

Comprehensive 2D chromatography employs a combination of two different columns and separation modes between the first and second dimensions (see figure 1) completely transferring a sample from the first dimension to the second dimension without significant loss of the first dimension resolution. It offers the best solution for multidimensional separation of complex polymer samples.

Since syntheses rarely yield a 100% conversion rate, 2D analysis can be helpful in separating the architectural product with different grafting density from non-grafted side chains (see GPC data) where it is clearly visible that a 1D analysis would not sufficiently separate the reaction mixture.

Partners in comprehensive 2D chromatography innovation

When combined with WinGPC UniChrom software from Germany-based Polymer Standards Service (PSS), Waters’ APC System enables researchers to gather an impressively high level of insight into their complex polymeric materials using a multidimensional separation approach – increasing the peak capacity of a single chromatographic analysis.

Waters partnered with PSS to bring a robust comprehensive 2D chromatography solution to the market. Their innovative solution enhanced the speed and solvent compatible capabilities of the APC system and leveaged the benefits of PSS software. It is a partnership that extends the prospects for the full characterisation of the most complex polymers and additives with multi-dimensional distributions.

‘Not only was comprehensive 2D chromatography very difficult in the past,’ says Bain. ‘It was time consuming and difficult to set up. We now have fully automated a 2D solution that includes a guided 2D set up with the software that controls the instrument – making the APC system an essential addition to polymer research laboratories across all industries,’ Bain adds.

Explore the technique deeper with Waters’ white paper Comprehensive 2-Dimensional liquid chromatography for polymer applications which is available to download free of charge.

No comments yet