BASF has officially begun construction on ‘one of the world’s largest’ industrial heat pump systems to provide steam for formic acid production at its Ludwigshafen site in Germany, as part of the firm’s efforts to move towards climate-neutral chemical production.

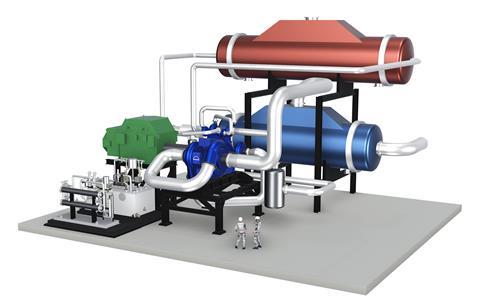

The system is being developed in partnership with GIG Karasek and will be powered by renewable electricity (allocated from BASF’s various renewable power agreements, which covered 26% of the firm’s total electricity consumption in 2024). With a thermal output of 50MW, or 500,000 tonnes of steam per year, BASF says the heat pump is expected to cut greenhouse gas emissions for the steam it supplies by up to 98%, equivalent to approximately 100,000 metric tonnes of CO2 annually.

Because heat pumps move heat rather than generating it directly, they can provide the same amount of heat output for a fraction of the energy input compared to fossil fuel systems. ‘Emission-free steam from the heat pump will partially replace fossil-based steam, helping us offer customers products with a lower carbon footprint,’ said Helmut Winterling, BASF’s president of European Verbund sites. The Ludwigshafen site requires around 15 million metric tonnes of steam per year in total.

Jan Rosenow, professor of energy and climate policy at the University of Oxford, UK, says the move is a very significant step. ‘BASF is the largest chemical company in the world,’ he points out. ‘[Putting its] weight behind heat pumps at this scale signals confidence in the technology in the chemicals sector and beyond.’

The heat pump will take in waste heat from one of the site’s two steam crackers. This is important for heat pumps that deliver high temperature outputs, says Rosenow, as the bigger the difference between heat input and output (the ‘temperature lift’), the less efficiently the heat pump operates. BASF says the system will ‘set new standards in terms of temperature lift and capacity’.

The football field-sized heat pump is scheduled for commissioning in mid-2027. The German government is supporting the project with up to €310 million (£270 million) through its Carbon Contracts for Difference programme, aimed at accelerating the market ramp-up of low-carbon technologies.

Rosenow explains that much of whether subsidies are necessary depends on the ratio of electricity to gas prices. The narrower this ratio, the more economically viable heat pumps become. ‘In the near future, government support will be essential in most countries,’ he says. As supply chains grow and capital costs come down, less financial support will be needed.

Rosenow says that existing heat pump technology could already displace most low and medium temperature industrial heat demand. But how fast and how far that change happens will ‘depend on whether governments and industry are willing to take bold action.’

No comments yet