By chemically modifying a soft film material, researchers in China have developed an especially lightweight, small and flexible refrigeration system, the most efficient of its kind.1 The device, developed by Xiaoshi Qian of Shanghai Jiao Tong University (SJTU) and colleagues, uses an electrical field to move the film and drive heat into and out of it. ‘This is the first experimental demonstration of materials that can serve as cooling and an artificial muscle,’ Qian tells Chemistry World.

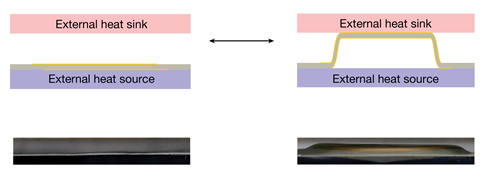

Applying an electrical field changes how disordered and strained the material is. That causes it to take in heat next to one surface, change shape to touch a different surface, release heat, then return to its original shape to start again. While the SJTU team has made films several square metres in area, they focus on circular films 20mm in diameter to cool down electronic chips.

The SJTU researchers rely on two scientific principles to make the device. The first, known as the electrocaloric effect, is caused by voltages applied to materials making them more or less disordered, increasing or lowering their entropy respectively. Temperature and entropy are related by the second law of thermodynamics. Systems take in heat as their entropy increases and release it as their entropy decreases.

Existing electrocaloric refrigeration systems use a cooling fluid, such as water, to carry heat away. This requires power supplies and pumps that make them bulky. To avoid this, Qian’s team uses a second principle, known as the electrostrictive effect, relating to the fact that electrical currents don’t pass across electrical insulators. In an electric field some electrically charged ions within the insulator do still move, with positively and negatively charged ions travelling in opposite directions. That movement pulls and stretches the insulating material, creating a force known as strain.

Elegant and compact

In the new cooling device, the SJTU team use force created by the electrostrictive effect to move a film, flexing it between different shapes. The film bumps up and down, using the electrocaloric effect to absorb heat at a hot surface and then release it at a metal heat sink that can carry heat away.

To make the new device, Qian’s team modified a soft film material known as a relaxor ferroelectric polymer. They had previously modified such relaxor ferroelectric polymers to maximise the amount of entropy change driving the electrocaloric effect.2 To do so, they put the material through a dehydrochlorination reaction, introducing double bonds. In the latest study, the team changed the ratio of components of the original polymer to maximise both the electrocaloric and electrostrictive effects.

The scientists measured the device to have a 32% thermodynamic efficiency, the best performance for an electrocaloric cooling device to date. They used it to cool down an electronic chip on a printed circuit board, reducing its temperature by 17.5°C in 50 seconds. The cooling power the device achieves per unit space ‘is nearly a hundred times higher’ than other reported devices, they claim.

‘It is a clever idea and the device is elegant, very compact,’ says Qibing Pei from the University of California, Los Angeles, who wasn’t involved in the study.

Emmanuel Defay from the University of Luxembourg agrees that the ‘main strength of this approach is its simplicity’. He calls the reported performance values ‘convincing’. ‘It confirms that electrocaloric materials can be very efficient,’ Defay adds.

Qian, however, stresses that the material is not ready for commercialisation. The material is too fragile, he admits. The voltage required to achieve the effect, 2000V, is also too high. ‘When you provide a device that can pump heat at the 100V level, then I think this can really move from a paper to industry,’ Qian says.

Update: A quote from Qibing Pei was updated on 21 May 2024 due to a misattribution.

References

1 D Han et al, Nature, 2024, DOI: 10.1038/s41586-024-07375-3

2 X Qian et al, Nature, 2021, 600, 664 (DOI: 10.1038/s41586-021-04189-5)

No comments yet