At COP28 over 20 countries pledged to triple the world’s nuclear energy capacity by 2050 in another step towards net zero. For many, this was a controversial declaration: the devastating consequences of nuclear accidents are well-documented and the fission process generates worrying quantities of long-lived radioactive waste with the potential for use in chemical weapons.

But, according to developers behind new thorium reactor technologies, the nuclear power plants of the future are very different from this historical picture. ‘You get thorium from rare earth refining, but it’s considered a nuisance material,’ says John Kutsch, executive director of the Thorium Energy Alliance in the US. ‘It should be the civilian nuclear fuel – it’s easier to handle than uranium, we burn it in a pure cycle, we have much less waste and you can’t make a bomb out of it.’

Conventional nuclear reactors use enriched uranium-235, the fissile minor isotope that makes up just 0.7% of natural uranium reserves on Earth. The major uranium-238 isotope is non-fissionable and significant pre-reactor processing is required to raise the percentage of uranium-235 to around 5%. Within the reactor core, these unstable nuclei fission spontaneously to release heat and neutrons, the latter then bombarding neighbouring nuclei and inducing further fission, sustaining the nuclear chain reaction.

However, only 5% of the fuel material can participate in productive nuclear reactions, with the remaining 95% instead forming hazardous long-lived transuranic products. ‘Where most of the fuel bar is made of U-238, you have quite a number of neutron captures,’ says Jean-Christophe de Mestral, chief financial officer of Swiss start-up Transmutex. ‘It becomes U-239 which converts into plutonium-239, which captures new neutrons so you have 240, 241, which then converts into americium. So you have a whole process here for the transuranics to be created in a uranium reactor and that’s very difficult, very active waste.’

The thorium fuel cycle

Transmutex is just one of the companies turning instead to the thorium fuel cycle and recently received a $23 million (£18 million) investment to develop their thorium reactor concept. Thorium-232 is a fertile material meaning it’s not itself fissionable but may be converted to a fissile material under specific conditions, such as those found in a cyclotron. ‘When it’s inside the core, the thorium is transformed because of the neutrons flying around [from the conventional nuclear waste],’ explains de Mestral. ‘So thorium-232 becomes thorium-233 which, by way of beta-decay, becomes protactinium-233 and again, this product is radioactive and becomes uranium-233.’

The unnatural uranium-233 isotope is fissionable and, as almost all the thorium is converted to uranium-233, this nuclear reaction does not produce any potent, long-lived transuranic products. Another huge advantage is that the chain reaction requires an initiator material to begin fission, with the reaction ceasing immediately upon its removal. And the ideal material to supply these vital initiating neutrons is the hazardous waste generated from conventional nuclear fission. ‘It’s an efficient machine to destroy nuclear waste and weapons so it brings quite some advantages in terms of existing waste management,’ says de Mestral.

Copenhagen Atomics is another company hoping to commercialise this alternative vision of nuclear energy and the team have plans to turn on their first prototype reactor within the next two years. But given these many advantages, why has it taken so long for this technology to attract commercial interest?

Unfortunate timing

According to Kutsch, this is largely down to bad timing. Many of the modern projects edging towards commercialisation are based on the molten salt reactor designed by Alvin Weinberg at the Oak Ridge National Laboratory in the 1960s. Typical reactors circulate a coolant around the reactor core, transferring heat away for use in electricity generation or other processes. However, focusing on creating a safer reactor, Weinberg mixed the fuel salts in with the molten coolant, creating a single self-regulating system.

‘When the fluid goes through the moderated section [which sustains the nuclear reaction by slowing down the neutrons], it gets hot and that’s where your fission is happening,’ explains Kutsch. ‘But as the molecules get hot, they spread apart and then they’re not close enough together to fission anymore. So they cool down and move closer together and then they can fission again. It’s self-regulating so there’s no prompt critical [event].’

Initial tests on uranium-235 and later uranium-233 successfully demonstrated this as a safe and successful reactor concept and the Oak Ridge scientists were keen to explore the potential of generating uranium-233 in situ from thorium. However, the project was decommissioned before these tests could take place with cold war demand for nuclear weapons unofficially blamed for the government’s decision to invest in proliferative uranium nuclear power over safer thorium technologies.

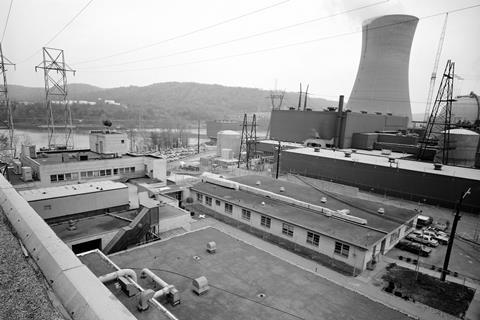

The thorium fuel cycle was largely forgotten until 1977 when the Shippingport nuclear plant in Pennsylvania was used as a trial reactor for thorium fuel. The reactor core, loaded with pellets of thorium dioxide and uranium-233 oxide, ran for almost 30,000 hours over five years, producing around 2.1 billion kWh of electricity before decommissioning in 1982. Analysis of the spent fuel revealed that the core contained 1.4% more fissile material than the initial fuel, indicating that successful thorium breeding had occurred. ‘These results were extremely positive and two reports were produced, one for the plant itself and one for the fuel,’ says de Mestral. ‘But the report for the plant was produced in March 1986 and one month later there was Chernobyl so this report was basically buried because the timing was really bad.’

The next generation

In the years since, there has been sporadic interest in reviving this technology, particularly as the cost of uranium fluctuated. But for Kutsch, the real focus on different reactor technologies started in 2000. ‘I think that there was a realisation that renewables were not going to be able to do the heavy lifting that some people had dreamed about, but that we also had left a huge amount of nuclear technology sitting on the table,’ he says.

Timeline

Countdown to a thorium future

1938–39

Fission fires up

Otto Hahn, Fritz Strassmann, Lise Meitner and Otto Frisch discover nuclear fission. The following year, Meitner and Frisch calculate and measure the energy of uranium fission and Hahn and Strassmann prove the possibility of chain reactions.

1951

Criticality milestone

Chicago Pile-1 becomes the first nuclear research reactor to achieve criticality.

1951

Electricity first

A small experimental breeder reactor at the Argonne National Laboratory in Idaho, US becomes the first nuclear reactor to produce electricity.

1956

Nuclear goes commercial

The first commercial nuclear power station at Calder Hall, Windscale in England is connected to the National Grid.

1965–69

Thorium thwarted

The Molten Salt Reactor Experiment at Oak Ridge National Laboratory in Tennessee, US reaches criticality but is decommissioned in 1969 before thorium can be tested as an alternative nuclear fuel.

1977–82

First for thorium

The Shippingport Atomic Power Station in Pennsylvania, US successfully demonstrates thorium breeding for the first time.

1986

Disaster strikes

Chernobyl nuclear disaster. Uranium prices plummet and interest in nuclear power declines.

1993

Burning waste

Carlo Rubbia proposes an accelerator-driven system as a means to incinerate nuclear waste and generate energy from thorium.

2000

The next generation

The Generation IV International Forum is launched to support the global development of safer next-generation nuclear technologies for deployment from 2030.

2018

Thorium reactor commissioned

The Chinese government grants approval for construction of the first thorium reactor in Gansu province.

2022

Thorium prototype

Copenhagen Atomics complete first prototype molten salt reactor unit.

2023

Nuclear commitment

Twenty-two countries at the COP28 summit commit to triple nuclear power output by 2050.

2025–26

Thorium future

Copenhagen Atomics hopes to deploy first 1MW thorium test reactor in a European country.

2028

Going commercial

Copenhagen Atomics hopes to deploy first commercial reactor.

Advanced reactors have finally begun to attract the interest of governments again, particularly across Asia. Nuclear is a central part of India’s strategy to achieve energy independence and thorium is a particularly attractive option, with the country home to 25% of the world’s reserves, compared with just 2% of global uranium. The government has invested heavily in a three-stage programme to develop the nuclear infrastructure for thorium energy and hopes to begin testing by December 2024. However, commercial exploitation of the country’s thorium reserves using breeder reactors is unlikely before 2050 and India has yet to build a reactor prototype.

China is perhaps closest to harnessing thorium power. The Shanghai Institute of Applied Physics began construction of a pilot thorium reactor in Wuwei city, Gansu province in 2018. The reactor, which was finished three years ahead of schedule, will use a blend of thorium and 20% enriched uranium-235 salts to generate an estimated thermal power output of 2MW. If this experimental reactor is successful, the country has plans for a larger-scale reactor with a capacity of 373MW by 2030.

In the west, legislative red tape is proving more of an obstacle to development. Several countries across Europe, including Switzerland and Germany, have completely banned construction of new nuclear power plants, while several others have phased out nuclear power entirely. But despite this apparent political antipathy, research into new technologies is thriving within the private sector.

A digital approach

The recent $23 million investment in Transmutex is perhaps indicative of the west’s slowly shifting attitudes to nuclear. The Swiss start-up builds upon decades of work started by physics Nobel laureate Carlo Rubbia at Cern in the 1990s.

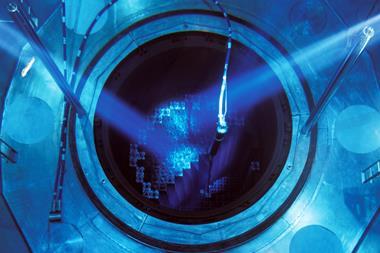

The company’s concept combines a particle accelerator called a cyclotron with a subcritical lead-cooled reactor. ‘It’s built with about 3% missing neutrons which is a very important safety feature for us – if you pull the plug on the accelerator the reactor stops in milliseconds,’ explains de Mestral. ‘This sub-criticality is also crucial in order to have an efficient machine able to transmute nuclear waste.’

When you talk to people, they’re stuck in a certain view of nuclear

Jean-Christophe de Mestral, Transmutex

However, rather than rushing to build a prototype, the Transmutex team intend to use this investment to develop a complete digital simulation of the whole reactor system. ‘We want to bring this virtual twin as far as possible so it will be faster and easier, with fewer mistakes to actually build,’ de Mestral says. ‘The second element is the selling or marketing process – we’re a private company so during this period we need to find a client: a state interested in building this system.’

At present, the accelerator-driven subcritical reactor system is unfamiliar to politicians and de Mestral cites the design’s complicated image as a possible reason for governments dragging their feet. ‘If you only want to produce electricity, maybe there are other systems that are simpler, but that’s not all we do,’ he says. The dual accelerator–reactor system is key to the design’s innate safety, non-proliferation and waste transmutation which the company believes are major selling points of the technology.

In particular, the team are marketing the design towards countries with concerns about their existing waste stockpiles and, according to de Mestral, conversations with governments, including the traditionally anti-nuclear Swiss parties, have so far been encouraging with Transmutex estimating that they could build their first reactor within 10 to 12 years. ‘Our project does not require research, it requires development,’ says de Mestral. ‘Nuclear power will be making a comeback and it will be a very strong and present market for thorium.’

Energy as a service

Commercial state-owned power generation is not the only application of this technology. Copenhagen Atomics is taking a completely different approach, focusing on small molten salt reactor units to meet the energy needs of private companies. The modular reactors each produce 100MW of thermal energy, with the possibility of combining an unlimited number of units for greater power output.

But rather than selling the reactors themselves, Copenhagen Atomics’ business model allows customers to effectively buy thermal energy as a service, with the company handling deployment, operation and decommissioning of reactors. ‘Our product is the heat source and then it’s for the customer to decide how they want to use it,’ says Jesper Glahn, chief commercial officer at Copenhagen Atomics, Denmark. ‘A huge energy use case is commodities and processes: it could be liquid fuels, solid-form fertiliser, green steel, desalination, mining – the market is endless.’

Founded in 2015, Copenhagen Atomics has already developed a 1MW prototype reactor and is currently seeking regulatory approval to deploy this system into a northern European country by 2026. At present, the UK is under consideration to host a trial of this technology and the company is currently in conversation with the National Nuclear Laboratory about a collaboration.

If the UK embraces this prototype experiment, Glahn says Copenhagen Atomics would like to build their first commercial reactor in 2028, deploying a further 300 units with a total capacity of 12GW by 2035. ‘There’s no investment by the UK government or UK taxpayers because of this as-a-service business model. This energy would be as an annuity £8 billion less than the current baseline on energy,’ he says. ‘There would also be a huge upfront saving because if you wanted to build Hinkley Point C with the same capacity, you would have to pay £160 billion.’

Currently, the biggest barrier to thorium power in the west is political will to commit to new nuclear technologies, but de Mestral hopes that as people become more familiar with this technology, these attitudes will change. ‘When you talk to people, they’re stuck in a certain view of nuclear which is the Generation II. But when we explain what Generation IV is: when we talk about small modular reactors and thorium systems, that changes a lot and there is a strong interest, even in political parties that are traditionally against nuclear,’ he says. ‘There are a lot of possibilities and it will be interesting to see how to combine them to meet the world’s needs.’

No comments yet