Researchers have reduced the cost of making a proton exchange membrane water electrolyser (PEMWE) by developing stainless steel-based components to replace titanium ones. PEMWEs can be used for green hydrogen production but the cost of titanium components had been limiting their commercial viability – a problem that this research could help address.

Green hydrogen is produced by electrolysers running on surplus renewable energy. It’s a promising alternative to fossil fuels and renewable technologies that rely on certain weather conditions and geographical locations. The most commonly used electrolytic methods for generating hydrogen are alkaline water electrolysis (AWE) and PEMWE. While PEMWE could potentially produce over 12 times more hydrogen than AWE, it has a higher capital cost due to its titanium cell components, namely its porous transport layers and bipolar plates. Titanium is used as it can resist the corrosive electrolysis conditions and avoids poisoning the device’s catalyst-coated membrane.

Aldo Gago, from the German Aerospace Centre, and colleagues have previously demonstrated that stainless steel can serve as a base material for bipolar plates by using a coating to protect it against corrosion. And other researchers have experimented with porous transport layers made from coated and uncoated stainless steel. The porous transport layers and the bipolar plates represent between 60–70% of the PEMWE stack cost so the opportunities for cost savings are significant. ‘Not only is the price of stainless steel lower, manufacturing sophisticated and complex structures in titanium is very expensive due to the tools that are required,’ explains Gago.

Building on their previous work, the team has now developed a working PEMWE cell with mainly stainless steel components. ‘There were two main challenges: protect the stainless steel against corrosion in such an aggressive environment, and use the cheapest stainless steel porous structure and modify it to achieve performances equal to any commercial electrolysers,’ explains Gago.

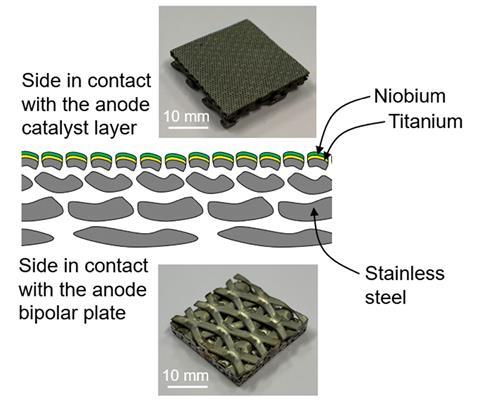

They used vacuum plasma spraying to coat four-layer mesh-type stainless steel porous transport layers with niobium and titanium. Using these coated porous transport layers alongside titanium-coated stainless steel bipolar plates on the anode side, and uncoated versions on the cathode side, they tested the cell’s durability using an accelerated stress test.

Not only did the coating protect against corrosion and catalyst poisoning, it also reduced electrical resistance. This meant an efficiency increase of 12% and comparable performance to commercial electrolysers. While this is important in reducing the cost of hydrogen production, Gago points out there are still challenges ahead. ‘There is still much to be done to reduce the cost of the electrolyser, electricity, water and many other factors that contribute to the high cost of green hydrogen. However, the use of stainless steel in PEMWE should have a positive impact on the cost, especially at large scales.’

‘I think the porous transport layers are going to be a fairly big challenge to do commercially,’ comments Katherine Ayers, vice president of R&D for Nel Hydrogen US. ‘That’s both the challenge and the opportunity – almost all of the components have room for cost reduction but you’re going to have to do all of them to get to the cost targets.’

References

This article is open access

S Stiber et al, Energy Environ. Sci., 2021, DOI: 10.1039/d1ee02112e

No comments yet