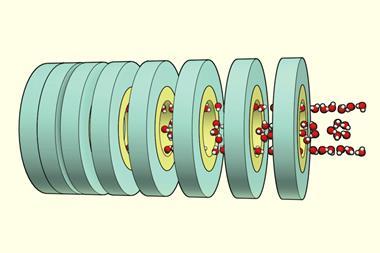

A new polymer membrane for separating hydrocarbons in crude oil might one day save huge amounts of energy by removing the need for fractional distillation. The polymer is similar to reverse osmosis membranes used for desalination of seawater, making it potentially scalable to the large volumes that would be needed in industry.

Fractional distillation of crude oil consumes nearly 1% of global energy and accounts for 6% of the world’s carbon emissions. In 2016 chemical engineers Ryan Lively and David Sholl at Georgia Institute of Technology in Atlanta, US, placed the isothermal separation of crude oil top of a list of ‘seven chemical separations to change the world’. Lively was subsequently part of the first team to demonstrate the process in 2020, using a spirocyclic polymer. Other groups have now demonstrated it using other materials.

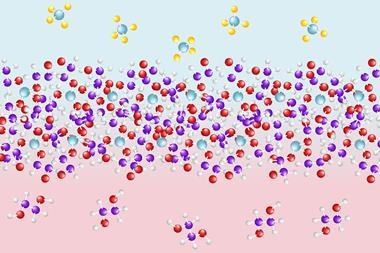

Reverse osmosis plants can desalinate large volumes of salt water many times faster than the world’s largest refineries can fractionate similar quantities of crude oil. They achieve this using membranes produced by interfacial polymerisation. This technique, which traditionally involves dissolving the two monomers – one in water and one in an organic solvent – to form a crosslinked polymer at the interface, is therefore highly attractive for scalable production of hydrocarbon-separation membranes.

Producing polymers to separate hydrocarbons poses specific challenges, however. First, for hydrocarbons to flow through them, the materials need to be lipophilic. However, as polymers are themselves hydrocarbons, membranes that are not structurally rigid may absorb the liquids and swell, altering the pore sizes and filtration properties. ‘Some of the materials worked quite well, but not really satisfactorily,’ says Tae Hoon Lee, a researcher at Sungkyunkwan University in South Korea, who helped develop the new membrane during his postdoc at the Massachusetts Institute of Technology (MIT) in the US. ‘That’s why we started this work to develop a proper polymer membrane for organic solvent reverse osmosis while still adopting the interfacial polymerisation technique.’

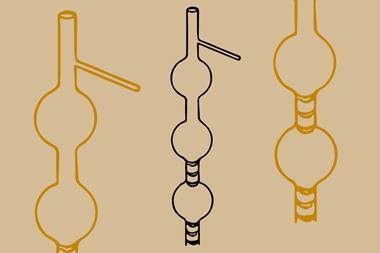

The researchers designed triptycene and spirobifluorene monomers that retained their shape when solvent passed through them. To join these together, they replaced the traditional amide linkages with less polar imine linkages – each formed by reacting an amine group on the triptycene with an aldehyde group on the spirobifluorene. As the monomers are insoluble in water, they dissolved both of them in the organic solvent, and instead dissolved the acid catalyst needed for the reaction to occur in the aqueous phase. The resulting microporous polyimine membrane showed continuous and stable ability to separate out the components of a mixture of naphtha-, kerosene- and diesel-grade fuel with efficiency better than state-of-the-art competitors and remained stable during 7 days of operation.

The researchers now hope to develop the process further and commercialise it. ‘What about the pharmaceutical industry and semiconductor industry?’ says MIT’s Zachary Smith, who led the project. ‘There’s many places where solvent separations or solvent–solute separations are needed. We’re looking to optimise, to scale, and to get this out into the real world.’

Lively, who was not involved in the present work, believes that, despite the inertia of industrial chemistry, ‘it is just a matter of time before a demonstration [of membrane crude oil fractionation] outside the university occurs’. He says this new idea is promising and the figures presented appear impressive, but cautions the technology is at an early stage. ‘I think separating a real crude oil needs to be tested,’ he says.

References

T H Lee et al, Science, 2025, DOI: 10.1126/science.adv6886

No comments yet