A rapid route to synthesise graphene capsules has been developed by researchers in the US and Korea. The capsules can be nano-engineered on demand and show promise in oil absorption.

Hollow spheres of graphene or graphene oxide (GO) have previously been made, but usually via complicated routes that involve the assembly of GO sheets onto template particles and then a separate template removal step. Now, a team led by Jiaxing Huang at Northwestern University and HeeDong Jang at the Korea Institute of Geoscience and Mineral Resources has developed a quick new route to synthesise graphene capsules in just one step.

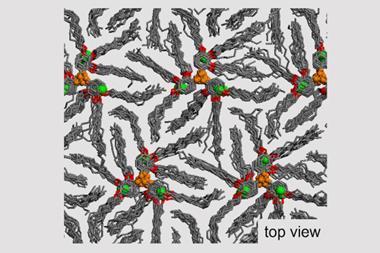

The scientists use a technique called aerosol spray pyrolysis to make their nanocapsules. They spray aerosol droplets containing GO sheets and a polystyrene template into a furnace. As the mixture enters the furnace the liquid rapidly evaporates, forcing the flexible GO sheets to mould to the template surface. Simultaneously, the GO is reduced and the template is burnt away creating graphene capsules in a single step.

Dan Li, an expert in graphene based materials at Monash University, Australia, says that 'this work presents a beautiful demonstration that the chemical behaviour of graphene-derived macromolecules is unique, which could lead to new powerful methods for synthesis of functional materials'.

Huang and Jang show that the graphene capsules have a high free volume and promising oil absorption properties, but they suggest that this is just the beginning. 'One advantage of the spray pyrolysis method is that one can incorporate multiple components into the aerosol droplets to serve different purposes,' say the researchers in their paper, adding that this makes the technique 'a very convenient tool for on demand engineering of the structures and properties of the resulting particles'.

References

- K Sohn et al, Chem. Commun., 2012, DOI: 10.1039/c2cc32049e

No comments yet