Scientists in the US have produced an economically viable, sustainable fire retardant by combining a waste product from water treatment plants with a viscoelastic hydrogel.

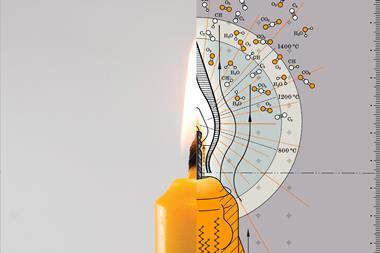

Wildfires are a serious problem in the US, threatening homes, lives and health with increasing prevalence. The US Forest Service aerially deploys thousands of cubic metres of fire retardant every year. This fire retardant typically consists of ammonium polyphosphate in water thickened with clay and polysaccharides.

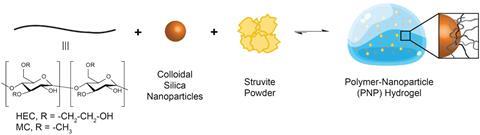

In 2016, Craig Criddle and Eric Appel from Stanford University reported a method for making a hydrogel that could be used to deliver fire retardants. It involved mixing cellulose derivatives (commonly used as viscosity modifiers) and colloidal silica nanoparticles together in water. ‘The main goal of engineering those materials was to improve the adherence of the sprayed retardant onto the vegetation of interest and improve its retention at that site to create a durable barrier that would last for the duration of the fire season,’ explains Appel.

While looking into other phosphorus-based chemicals, they discovered an obscure reference to magnesium ammonium phosphate being used as a flame retardant for textiles. Magnesium ammonium phosphate, or struvite, is well-known as an inconvenience in the water industry. ‘It’s usually a pest’, says Criddle. ‘It tends to block pipelines and precipitate in places where we don’t want it, and so people will invest quite a bit of energy and cost to remove it.’

The group wondered if struvite would work with their hydrogel in a wildfire setting, given that it has similar chemical properties to ammonium polyphosphate. So they ground struvite pellets into a fine powder and mixed it into the hydrogel by shaking them together in a bottle. Subsequent experiments suggested that struvite-suspended hydrogels are as good at fighting fire as commercial ammonium polyphosphate-based fire retardants, and even better at sticking to surfaces.

Currently, struvite recovered from waste streams tends to be used as a slow-release fertiliser, however this is not the most cost-effective use of the crystals. Investigations into the value of the struvite recovered for firefighting purposes showed that it was the second most valuable resource obtained from the wastewater treatment train, after the water itself. Further analyses showed that there is enough struvite produced as waste throughout the US to meet the demands of wildfire suppression programmes. Therefore, using it as a fire retardant could be economically viable as well as environmentally friendly. ‘Struvite as a green source of wildland fire retardants recycled from wastewater has a lot of potential to reduce the need for mined phosphorus and promote cleaner water bodies,’ adds Appel.

Andrea Hicks, a sustainability expert at the University of Wisconsin-Madison in the US, comments ‘The economic discussion is particularly interesting, as the firefighting agent would have a greater value than what is currently found when the struvite is sold for fertiliser, and has the potential to incentivise more struvite production from wastewater treatment plants.’

Appel launched a start-up called LaderaTECH to commercialise the wildfire prevention technology. In May 2020, LaderaTECH was acquired by Perimeter Solutions, which produces all the fire retardants used by the US Forest Service.

No comments yet