Anti-reflective coating could improve solar cells

Meet the blackest thing in the world. Researchers have unveiled the least shiny material ever made, a chunk of pure darkness that has the most anti-reflective coating known to science.

The special coating relies on a nanomaterial that has a refractive index almost equalling that of air. These films could be used to improve the efficiency of solar cells, to make brighter solid-state lighting devices, or to create a ’black body’ - a hypothetical material that reflects no light.

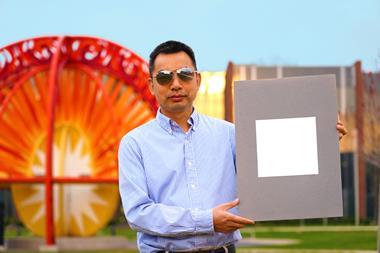

The thin multi-layered films created by Fred Schubert and colleagues from the Rensselaer Polytechnic Institute, New York, US, cut out reflection from a broad spectrum of light wavelengths striking their surfaces at all angles; at best, just 0.1% of light hitting the surface is reflected. That’s in stark contrast to conventional single-layer coatings which tend to cut out one single wavelength of light, and whose performance drops off as light strikes them at more oblique angles.

The key to the new coatings is a material with a record low refractive index - the fundamental property determining how fast light can travel through the material, and how it reflects, refracts, or diffracts at surfaces. By depositing silica nanorods at around 45? onto a thin film of aluminium nitride, Schubert’s team managed to create a porous material with a refractive index of 1.05, very close to air’s 1.0.

According to laws formulated in 1821 by French physicist Augustin-Jean Fresnel, the closer the refractive indices of two materials, the less light is reflected at their boundary. So the next challenge for the US researchers was to create a smooth gradient of materials running the gamut of refractive indices from air to aluminium nitride; at each interface, as little light as possible would be reflected back.

Such ’graded-index’ coatings have been investigated before: their mathematical basis was first demonstrated by Lord Rayleigh in 1880. But before the new silica rods, no optical material could come close to matching air’s refractive index; the coatings had therefore always reflected too much light at the first hurdle.

Schubert’s team deposited a series of five silica and titanium oxide porous nanorod layers onto aluminium nitride film. Each successive layer, around 100 nm thick, had a slightly lower refractive index, carefully controlled by the angle of nanorod deposition. The final coating effectively eliminated light reflection. There’s room for improvement, Schubert conceded, since one could always add even more finely graded nanorod layers, but five seemed practically sufficient for the proof-of-principle material.

The coating could be useful for any situation where researchers needed to get light into or out of a material, Schubert said. For example, it could increase solar cell efficiency, by allowing more sunlight to reach the cell’s active region. It could make LEDs brighter by eliminating reflection, or even create a ’black body’, a material which reflects no light at all. And the ability to precisely control a film’s refractive index in this way means that the same ideas could be used to make ultra-reflective materials too, the team suggest.

Richard Van Noorden

References

J-Q Xi et al, Nature Photonics, 2007 DOI:10.1038/nphoton.2007.26

No comments yet