Arm can pick up, place and release molecule cargo mimicking factory assembly line

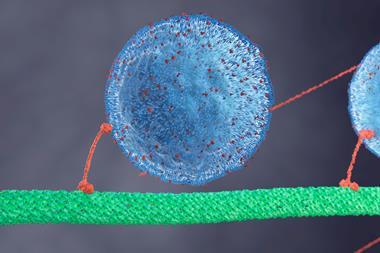

UK chemists have devised a nanoscale robot that can grasp a cargo molecule, pick it up, place it in a new position some distance away and release it. At no time does the cargo dissociate from the machine or exchange with other molecules. While such a sequence of actions is trivial on a macroscopic scale, to achieve it synthetically with small molecules is unprecedented and could mark the start of a new era of molecular robotics. Multiple similar robots in sequence could, for example, replicate a factory’s assembly line to build increasingly complex molecular structures.

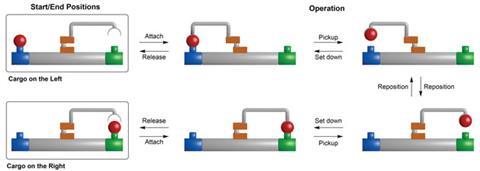

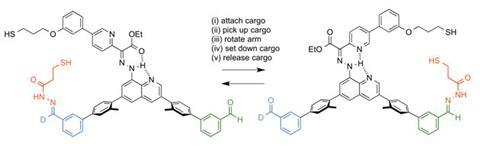

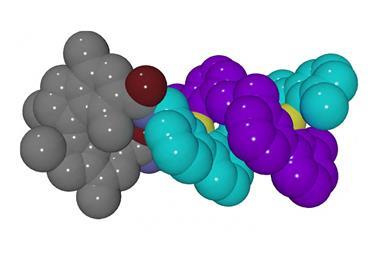

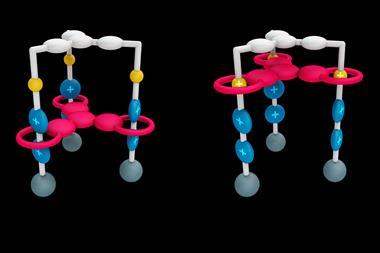

The robotic molecule, developed by David Leigh’s laboratory at the University of Manchester, consists of three main components: a rotatable arm, a molecular platform and the small cargo molecule, 3-mercaptopropanehydrazide. The robot arm sits in centre of the platform, at either side of which is an aldehyde group. The cargo molecule attaches at one side of the platform through a covalent hydrazone bond with the aldehyde on that side of the platform.

The gripping end of the robot arm possesses a thiol group. In the presence of iodine under basic conditions the thiol group of the arm and the cargo react to form a disulfide bond. The cargo is now attached to both the gripper and the platform. When acid is added, three processes occur sequentially. First the disulfide bond connecting the gripper and the cargo becomes locked, secondly the hydrazone bond between the cargo and the platform is loosened, and there is a rearrangement of hydrogen bonds at the nitrogen-rich fulcrum of the robot arm. This introduces strain, causing the arm to swing across to the other side of the platform, taking the cargo with it.

Basic robot

Once the cargo is the vicinity of the aldehyde group on the far side of the platform it attaches via a hydrazone bond and a change to basic conditions locks it in place. This also loosens the grip of the arm, depositing the cargo in its new position, around 2nm from where it started. Repeating the process under slightly different conditions of acidity causes the arm to pick up the cargo, swing it in the opposite direction and release it back to its original position.

‘We are very excited about this,’ says Leigh. ‘We have taken components from the existing supramolecular toolbox and combined them into a multicomponent molecular machine where we can programme the movement of molecules to accomplish a task through highly synchronised dynamic covalent chemistry.’

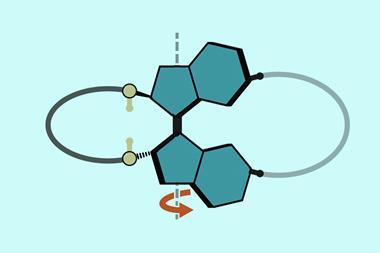

This simple molecular device could represent an important stage in the evolution of synthetic molecular machines, Leigh suggests. ‘I think this shows that a multicomponent assembly can do much more than the sum of its parts, and could open the way to more complex structures. For example if we put lots of these in series we could pass a cargo from one arm to another – similar to a factory assembly line.’

‘Stunningly efficient’

Other experts in the field have applauded the group’s achievement. ‘This is another stunningly elegant molecular machine from the Leigh group,’ says Euan Kay of the University of St Andrews in the UK. ‘They have brought together several cutting-edge synthetic molecular machine components, and combined these to perform a task that has until now been beyond fully synthetic molecular machines.’

Kay adds: ‘In terms of operation, on one hand this machine is stunningly efficient: about 80% of the robots work properly on any given cycle, which in molecular terms is very, very good. But on the other hand, the pickup–reposition–release cycle involves five distinct operator inputs – and these are chemical inputs, each of which generates resulting waste. Achieving these sorts of complex machine operations but using just a single stimulus to trigger an ordered cascade of processes is one of the next important challenges for the field, as is finding ways of dealing with the waste and having machines work for multiple cycles with no drop-off in efficiency.’

Feihe Yuang of Zheijiang University in China comments: ‘This amazing work is a significant step forward in the development of artificial molecular machines that work, and provides novel thought to manipulate substrates for controllable molecular construction in the future. Meanwhile, continuous cargo transporting as factory assembly lines will be worth the wait.’

References

S Kassem et al, Nat. Chem., 2015, DOI: 10.1038/nchem.2410

No comments yet