Binding strengths of polymer–boron nitride nanotubes are higher than those reported for carbon nanotubes

Boron nitride nanotubes reinforced with polymers have been shown to be even stronger than carbon nanotube composite counterparts. Carbon nanotubes on their own have been estimated to be at least 30 times stronger than Kevlar – a synthetic fibre specifically engineered by DuPont to stop bullets.

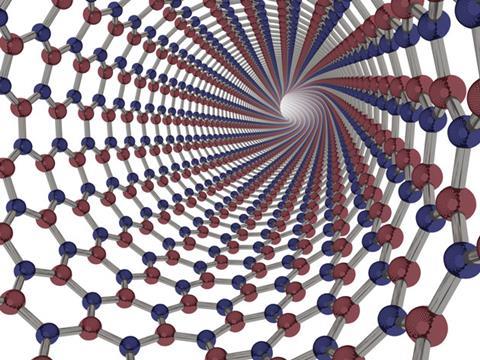

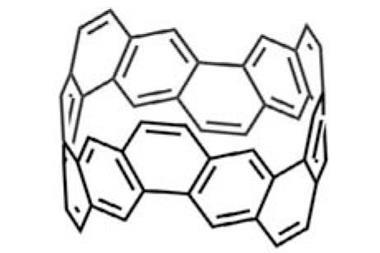

Like carbon, boron nitride can form single atom thick sheets that can roll up into cylinders to create nanotubes. Boron nitride nanotubes alone are almost as strong as carbon nanotubes, but their real advantage in a composite material is how strongly they can bind polymers.

Changhong Ke, at the State University of New York at Binghamton, and colleagues used a nanomechanical test to probe the strength of the interface between polymers and boron nitride nanotubes in composites of the two materials. They found that binding strengths were higher than those reported for carbon nanotube composites – 35% higher for the poly(methyl methacrylate) interface and approximately 20% higher for the epoxy interface.

The researchers suggest that boron nitride nanotubes bind more strongly to polymers because of how the material’s electrons are arranged. In carbon nanotubes, carbon atoms share electrons equally. However, in boron nitride, nitrogen atoms monopolises more of the electrons in the bond. It is this unequal charge distribution that seems to create a stronger attraction between the boron nitride and the polymer molecules, which was demonstrated in molecular dynamics simulations carried out by Ke’s team, along with a group at the University of Georgia.

However, the major drawback of boron nitride nanotubes is their cost. They sell for about $1000 (£675) per gram, while carbon nanotubes cost between $10 and $20 per gram.

The main reason boron nitride nanotubes are so expensive is because production volumes are still low, Ke explains. He notes that boron nitride nanotubes are quite difficult to synthesise because of their curved cylindrical geometry. ‘Researchers have been working on efficient production methods with high yield, in particular those can be scaled up for mass production,’ Ke tells Chemistry World.

He says the price of carbon nanotubes in the 1990s and early 2000s was ‘orders of magnitude higher’ than their current cost, suggesting that the price of boron nitride nanotubes will continue to drop in future.

Ke describes boron nitride nanotubes as ‘multi-functional materials’. They are light, have excellent mechanical and thermal conductivity properties, and can survive high temperatures. Boron nitride nanotubes are also chemically inert, and can absorb neutron radiation. These properties make them useful as mechanical or thermal reinforcing additives for polymeric, ceramic and metallic composites. Additional applications of boron nitride nanotubes include use as protective shields, electrical insulators and sensors.

References

X Chen et al, Appl. Phys. Lett., 2015, 107, 253105 (DOI: 10.1063/1.4936755)

No comments yet