Interest for testing from L’Oréal, BASF and Procter & Gamble could be a stepping stone towards bespoke organs

3D bioprinting’s allure has attracted blooming interest from the skincare industry, with three leading firms each launching skin printing initiatives in mid-2015 that they hope will revolutionise cosmetic testing. The initial challenge is making skin slivers for new product experiments conducted in multiwell analytical plates, but success could lead to much grander schemes. The expertise gained could feed into pharmaceutical research, and even help enable patients’ own cells to be made into almost perfectly compatible skin grafts and eventually replacement organs.

Two projects are partnerships with startups: L’Oréal’s US-based global technology incubator has joined forces with Organovo in the US; and German-headquartered BASF with French firm Poietis. Meanwhile, US consumer products giant Procter & Gamble has invited research proposals from Singaporean academics within a five-year S$60 million (£27.4 million) programme with the country’s Agency for Science, Technology and Research (A*Star).

Today skin tissue is routinely grown in cell culture, explains Priya Viswanathan from King’s College London, but producing a centimetre-square piece can take up to four weeks. Using the same initial cells, which for lab testing purposes are typically donated by plastic surgery patients, 3D printing can potentially do the same in less than a day. Skin is a multi-layered organ with different cell types, and 3D bioprinting is well suited to depositing cells in that arrangement. ‘You still need to grow the cells, but printing in a multilayer format you wouldn’t need to culture it additionally for that much longer,’ Viswanathan says.

Bioinks for 3D printing can be created by dispersing cells in a standard culture medium. Any printing technology could theoretically then be used to deposit them, Viswanathan explains, making experiments relatively cheap and easy. However, dedicated tools are likely to deliver better results, making them especially attractive if they’re affordable. ‘The lower the cost of the manufacturing and the better the resolution of the printer, the easier it is to take into biological applications,’ Viswanathan underlines.

Challenges inevitably accompany these benefits. The hurdles that stand in the path to skin with full natural functionality include preventing the heat generated in the printing process damaging cells’ health, or viability. It’s also ‘extremely difficult to print the entire complexity of any organ or tissue including the vasculature’, explains Viswanathan, because real tissue needs biochemical inputs including growth factors and cytokines. ‘We rely on the fact that cells produce these themselves, which is good but means that you’re missing a lot of the key ingredients,’ she adds. Additionally, natural tissues combine different types of cell, giving printers a tough choice between simplified single cell-type or complex multiple cell-type processes.

Inkjet or laser printer?

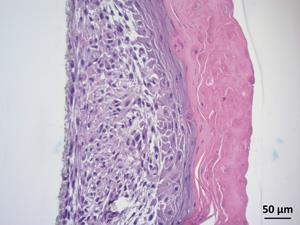

Organovo aims to use its 3D printing method to create a convincing version of cells’ natural growth microenvironment. ‘Our goal with each of our tissues is to recapitulate the biochemical production of proteins and enzymes, the gene expression and histology of native tissue,’ says Michael Renard, Organovo’s executive vice president for commercial operations. ‘Our technology allows for the precise control of the spatial relationships between various cell types to mimic the form and function of native tissue.’

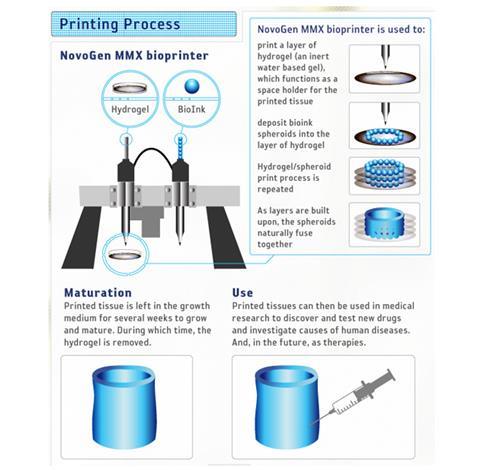

The company’s approach, built on research originating from the University of Missouri’s Gabor Forgacs, uses an ink of cultured cells, formed into spheroids. Its printer deposits ink via a capillary tip with one print head into layers of hydrogel dispensed with a second print head. The spheroids naturally fuse together and are left to grow for several weeks, over which time the hydrogel is removed. Organovo has previously produced nerve guides, blood vessels, lung tissue and cardiac sheets or patches. ‘We have already built multi-layered skin consisting of dermis and epidermis layers,’ Renard adds. Organovo’s partnership with L’Oréal involves developing 3D printed skin tissue for product testing and other areas of advanced research, ‘building new breakthroughs in skin modelling’.

Time to mature

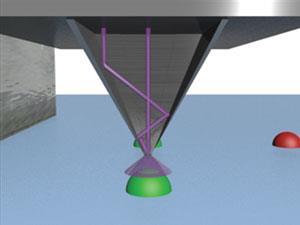

Reflecting the importance of self-organisation as printed tissue matures, Poietis calls its approach ‘4D bioprinting’, where the fourth dimension is the architecture that evolves between printing and readiness. To make the first three dimensions it coats cells and surrounding materials, such as hydrogels or collagen, tens of micrometres thick onto glass slides. The bioprinter uses a laser to detach picolitre droplets from the slides, depositing them with high precision and resolution, according to Bertrand Viellerobe, the company’s chief technology officer.

‘Different technologies such as bioextrusion or inkjet are complementary, but laser is the best so far,’ Viellerobe claims. ‘The viability of cells is the highest and it’s the only one capable of single-cell printing in very high precision.’ Printing 10,000 drops per second, the template for one layer in the centimetre-square skin pieces used for testing can be formed in less than 30 seconds, he adds. ‘For skin we need to do multilayer printing, in this case it would still take less than ten minutes, and the fourth dimension depends on the type and function of the tissue. Today the standard maturation will be in the range of several days to 1–2 weeks.’

The printed structure serves as a blueprint for the final tissue, but evolution during maturation is also a critical process that must be studied closely, Viellerobe stresses. As well as the geometry of the cells, parameters such as temperature, nutrients and growth factors, oxygen and carbon dioxide levels must be optimised while they incubate, he explains.

Going for the hard cells

BASF’s initial 3D printing focus is its skin model technology, Mimeskin. BASF’s tissue engineering and cell culture expert Sebastien Cadau says that his company was attracted to work with Poietis because of the high resolution its system offers. ‘This allows better understanding of the skin mechanisms when it comes to the development and testing of advanced cosmetic bioactives for skin care,’ he says. ‘We are convinced that thanks to this new technology it will be easier to build complex biological patterns, for instance. Other expected advantages include higher predictability before in vivo clinical studies, higher throughput studies (bringing cost and time savings) and higher reproducibility.’ The throughput advantage comes because automated reproduction of Mimeskin tissue will take just 1-3 days.

Cadau is confident that the combination of BASF and Poietis’ expertise will enable them to quickly identify the constituents needed for the best cell development and self-organisation environment. ‘The goal is to obtain the closest model to human skin, with various dermal and epidermal markers to characterise the future bioprinted skin,’ he says. ‘We will be able to assess the efficacy of active ingredients on defined targets and it will help us in a better understanding regarding unknown skin metabolic pathways.’

Beyond Mimeskin, the BASF–Poietis collaboration is due to proceed to more advanced models containing additional cell types. ‘We are focusing first on fibroblasts and keratinocytes, which are the main cells in skin, and then on other dermal or epidermal cell types, such as endothelial cells, melanocytes or immune cells,’ Cadau says. ‘Mastering the complexity of biology is an endless path, but each technical improvement increases our knowledge. In the near future, complex structures with different cell phenotypes could be addressed, such as sebaceous glands or hair follicles, and will depend less on self-organisation.’

In its own research, Poietis is working on printing full-thickness human dermis and epidermis, with Viellerobe hinting at promising results for printing them separately, albeit missing some biological markers. ‘We’re quite confident that with time we’ll be able to fit these layers together,’ he adds.

The anti-Frankenstein?

While recent deals have focused on using 3D bioprinted skin for cosmetic testing, all of the companies involved are also looking further. ‘The field of application has no limit,’ Cadau stresses. ‘Each application previously using 3D models could be replaced by 3D bioprinted models with cost and time savings. Bioprinting will also have a huge impact on skin grafts and patient healthcare.’

Renard highlights that designing and creating functional, three-dimensional human tissues for both medical research and therapeutic applications is exactly Organovo’s aim. ‘We are collaborating with pharmaceutical and select partners to develop human biological disease models in three dimensions,’ he says. ‘These 3D human tissues have the potential to accelerate the drug discovery process, enabling treatments to be developed faster and at lower cost. Because our mission is to build tissues for use in both the laboratory and the clinic, we look to leverage our R&D investment across that continuum.’

3D printing skin could revolutionise grafting operations, Viswanathan highlights, using a small sample of cells to cover a large area and changing the medical procedure itself. ‘You have the ability to print cells very quickly onto the wound site, and enable its repair much faster,’ she says. She highlights research on printing skin directly onto burns at the US Armed Forces Institutes of Regenerative Medicine, led by Wake Forest University in Winston-Salem, North Carolina. ‘Because this has to be used in combat the technology is portable,’ she underlines.

And unlike some biotechnological innovations, using 3D bioprinting to provide replacement body parts using a patient’s own cells is relatively popular, asserts Viellerobe. Consequently, alongside its conventional startup funding, Poietis is seeking to raise €600,000 (£436,000) through crowdfunding by early October. ‘Everyone can understand and see that it will be useful for healthcare,’ Viellerobe says. ‘If someone has had cancer and part of their skin has been removed, you can take other cells from the patient and make very similar tissue in terms of colour, hair follicles, and vascularisation. Maybe you won’t even see where the graft is. The ultimate vision is to print every type of cell with very high precision to make every type of tissue or organ.’

No comments yet